In the construction and operation of quarries, the design of the crushing process is the cornerstone determining investment costs, operational efficiency, and product quality.

Among these decisions, "Should we use two-stage crushing or three-stage crushing?" is a primary technical decision faced by almost all investors and engineers.

There is no absolute "right" or "wrong" choice, only whether it is the "most suitable." This article will provide an in-depth analysis of the advantages and disadvantages of the two processes and offer a scientific basis for selection.

Stone Crushing Plant PDF, Download ↓↓↓

I. Understanding Two Mainstream Crushing Processes

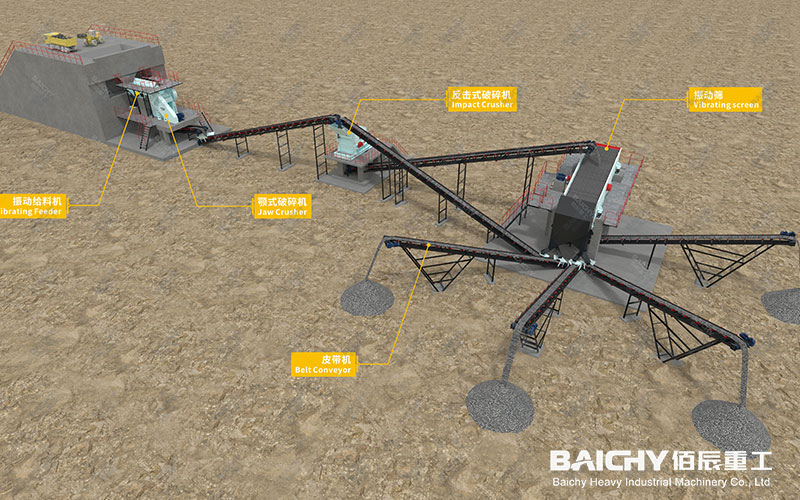

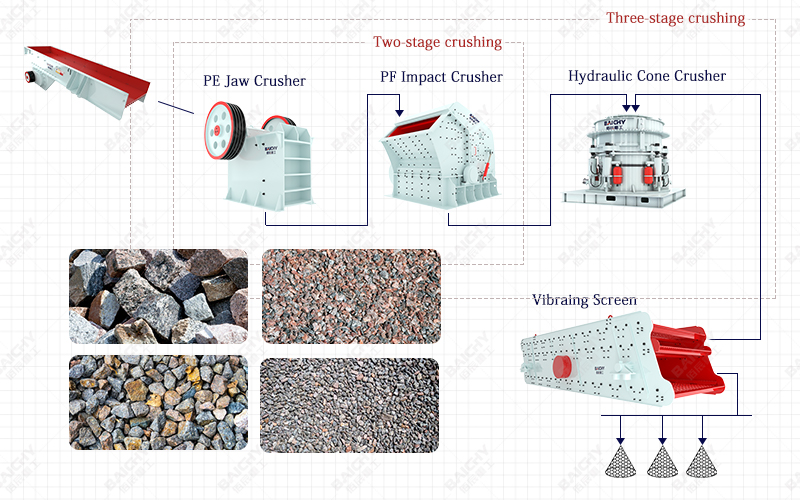

1. Two-Stage Crushing Process:

◦ Process: Coarse crushing (jaw crusher) → Medium and fine crushing (impact crusher or cone crusher) → Finished product screening.

◦ Features: Simple system, fewer pieces of equipment, lower investment cost, and smaller footprint.

◦ Disadvantages: High performance requirements for the crusher; relatively difficult to control product particle shape; suitable for applications with less stringent particle size requirements or smaller raw material particle sizes.

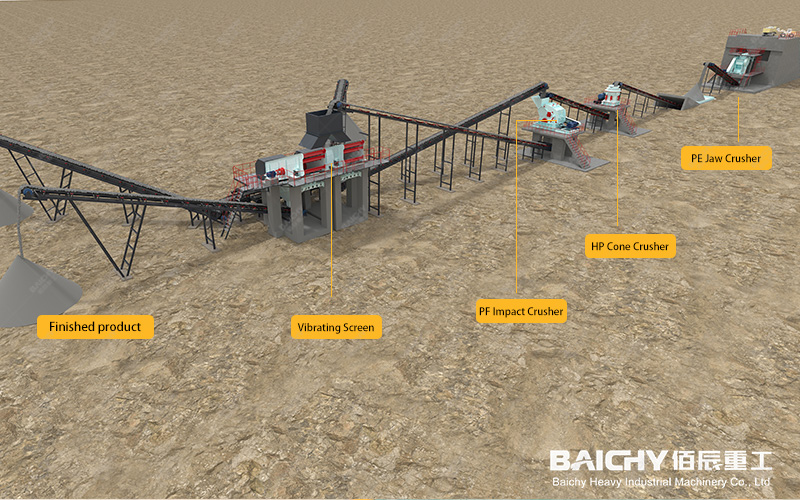

2. Three-Stage Crushing Process:

◦ Process: Coarse crushing (jaw crusher) → Medium crushing (cone crusher) → Fine crushing (cone crusher or vertical shaft impact crusher) → Finished product screening.

◦ Features: Large crushing ratio, uniform product particle size, good particle shape, high system flexibility, and potentially lower total energy consumption.

◦ Disadvantages: Long process flow, large equipment investment, large footprint, and relatively complex operation and management.

II. How to Choose?

Which process is suitable for your quarry? Please make a comprehensive judgment based on the following five core factors:

1. Physical properties of the raw material (hardness, particle size, mud content)

• High-hardness materials (e.g., granite, basalt): Three-stage crushing is recommended. Using a cone crusher in the medium crushing stage is more efficient and has lower wear costs for hard rock. If two-stage crushing is forced, the impact crusher's hammers will wear very quickly, leading to a surge in operating costs.

• Medium-low hardness materials (e.g., limestone): Two-stage crushing is an economical and efficient choice. Impact crushers not only crush but also shape the aggregate, resulting in products with better particle shape.

• Large raw material size: If the raw stone from blasting is very large, three-stage crushing can achieve gradual crushing at each stage, reducing the load on a single unit.

2. Design capacity requirements

• Small to medium capacity (below 500 tons per hour): Two-stage crushing is preferred to control initial investment.

• Large capacity (above 500 tons per hour): Three-stage crushing has significant advantages. It rationally distributes the total crushing task across three machines, avoiding overly large single-machine specifications, resulting in more stable system operation, easier maintenance, and potentially lower energy consumption per unit product.

3. Final product specifications and market demand

• Demand for multiple aggregate specifications (e.g., simultaneous need for 0.5, 1.2, and 1.3 grit): The screening circuit of three-stage crushing is more flexible, making it easier to accurately control the particle size and proportion of each stage of the product.

• Primarily producing high-quality manufactured sand: A three-stage crushing process is essential, with the final stage using a vertical shaft impact crusher (sand making machine). This is crucial for obtaining high-value manufactured sand with excellent particle shape.

• Product requirements are singular, with less stringent particle shape requirements: Two-stage crushing can meet basic needs.

4. Investment and Operating Cost Budget

• Tight budget, seeking quick returns: Two-stage crushing has lower initial equipment investment and civil engineering costs.

• Focus on long-term benefits and operating costs: Although the initial investment for three-stage crushing is higher, the cost of its wear parts (such as the mantle and crushing wall of a cone crusher) is generally lower than that of the hammer plate of an impact crusher, and power consumption is more rationally distributed, potentially making it more economical in the long run.

5. Site Conditions and Layout

• Limited space, steep slope: Two-stage crushing has a shorter process flow and a more compact layout, making it a more realistic choice.

• Flat site, ample area: Provides ideal layout space for three-stage crushing, utilizing the slope to achieve gravity flow of materials and reduce conveying equipment.

Conclusions and Recommendations

| Characteristics | Two-stage crushing recommended | Three-stage crushing recommended |

| Material Hardness | Medium to low hardness (e.g., limestone) | High hardness (e.g., granite, basalt) |

| Capacity Scale | Small to medium (≤500t/h) | Medium to large (>500t/h) |

| Product Requirements | Ordinary aggregate, not demanding on particle shape | High-grade aggregate, high-quality manufactured sand, multiple specifications |

| Investment Budget | Limited budget, control initial investment | Sufficient budget, focus on long-term operational benefits |

| Site Constraints | Small site | Open site |

Final Recommendation: Choosing a crushing process for a quarry is a complex systems engineering decision. The most reliable approach is to collaborate with a professional mining design institute or experienced equipment supplier, providing detailed raw material testing reports, capacity targets, and product plans. Experts will conduct simulation calculations and techno-economic comparisons to tailor the optimal crushing solution for you. Making the right choice is the first step to your quarry's profitability.