In the sand and gravel aggregate industry, granite, with its high hardness, high compressive strength, and durability, has always been the preferred raw material for high-quality building materials. However, its high hardness also poses a severe challenge to crushing equipment.

A scientifically designed crushing production line with powerful and reliable core equipment is key to success. For medium-scale production lines with an hourly output of 100-150 tons, the PYB1200 spring cone crusher is undoubtedly a "powerful engine" for the medium crushing process, making it an ideal choice for many investors due to its superior performance.

I. Why is the PYB1200 cone crusher a "perfect match" for granite crushing?

The PYB1200 is a standard spring cone crusher, its design perfectly matching the requirements of medium crushing (secondary crushing) processes for granite.

1. Powerful crushing capacity and applicable particle size: The PYB1200 has a feed opening size of 145mm and a maximum allowable feed particle size of 160mm, perfectly handling the primary crushing products of jaw crushers (such as PE600×900). Its production capacity precisely covers the range of 100-150 tons/hour, accurately matching the target output and avoiding overcapacity or undercapacity.

2. Unique Layered Crushing Principle: For high-hardness granite, the cone crusher employs a layered crushing principle, achieving crushing through the mutual compression and grinding between particles. This not only ensures high efficiency but also effectively reduces the content of needle-like and flaky particles, producing cubic aggregates with excellent gradation and higher product value.

3. Spring Safety Device for Safe and Reliable Operation: The equipment's built-in spring overload protection system automatically releases pressure when uncrushable materials (such as iron blocks) enter the crushing chamber, increasing the discharge opening and allowing the foreign object to escape. This protects the core components of the main unit (such as the main shaft and cone) from damage, greatly improving the stability and service life of the equipment when crushing high-hardness materials.

4. Stable operation and uniform output: Compared to other crushing equipment, the PYB1200 cone crusher operates smoothly with low vibration and noise, continuously producing intermediate products with uniform particle size, laying a good foundation for subsequent sand making, shaping, or screening processes.

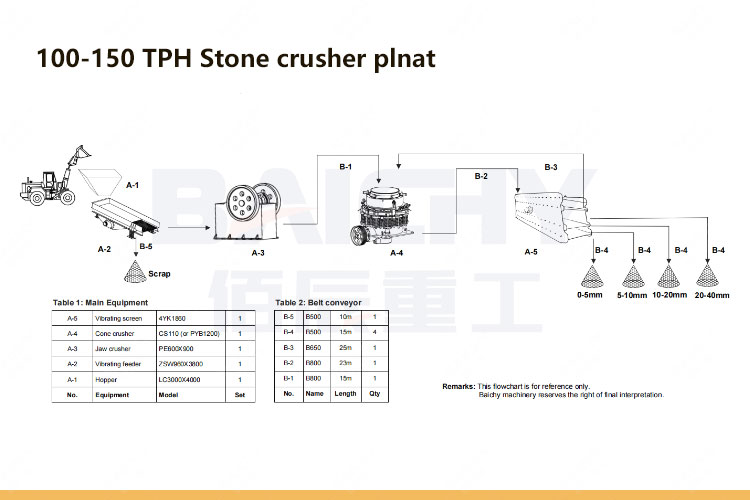

II. Core Configuration Scheme for a 100-150 Tons/Hour

Granite Production Line An efficient production line is the result of "multi-machine collaboration". A typical granite crushing production line, centered around the PYB1200, is configured as follows:

• Feeding Stage: ZSW490×110 vibrating feeder (uniform and continuous feeding)

• Coarse Crushing Stage: PE600×900 jaw crusher (crushes large granite pieces to ≤160mm)

• Medium Crushing Stage (Core): PYB1200 spring cone crusher (crushes stones smaller than 160mm to ≤60mm medium particle size)

• Screening Stage: 3YK1860 vibrating screen (screens the crushed material according to different particle size specifications; qualified products are stored, and oversized particles are returned to the cone crusher or enter the next stage)

• (Optional) Fine Crushing and Sand Making Stage: For extremely high particle shape requirements or the need for manufactured sand, a multi-cylinder hydraulic cone crusher or impact crusher can be configured.

Advantages of this configuration: Simple process, reasonable equipment investment, controllable operating costs, and excellent product particle shape, fully meeting the crushing needs of 100-150 tons of granite per hour.

III. Core Value of Investing in a PYB1200 Cone Crusher Production Line

1. High Return on Investment: The equipment is robust and durable with a low failure rate, ensuring continuous and efficient operation of the production line, maximizing uptime, and quickly recovering investment costs.

2. Superior Product Quality: The produced 12-13, 13-25, and 25-60mm stones have good particle shape and reasonable gradation, resulting in strong market competitiveness and higher selling prices.

3. Low Long-Term Operating Costs: Core wear-resistant parts (such as the mantle and crushing wall) are made of high-manganese steel, offering strong wear resistance and long replacement cycles, effectively reducing the consumption cost of vulnerable parts per ton of stone.

Choosing a suitable core intermediate crushing equipment is one of the decisive factors in the success of a granite crushing production line. The PYB1200 spring cone crusher, with its specialized design for high-hardness materials, stable and reliable spring protection system, and precisely matched capacity, has proven its irreplaceable value in production lines with an hourly output of 100-150 tons. If you are planning a high-efficiency, profitable granite crushing production line, the PYB1200 is undoubtedly a trustworthy partner.

Feel free to contact us anytime for a customized equipment quote and production line design!