In fixed production lines in large-scale mining, building materials, metallurgy, and other fields, the crushing system is the "first checkpoint" for raw material processing. The rationality of equipment selection directly impacts the efficiency, cost, and final product quality of the entire production line. Faced with a wide variety of crushing equipment, every project manager must face the challenge of choosing the optimal one based on material characteristics, production capacity requirements, and finished product requirements.

This article systematically reviews several core types of crushing equipment for fixed production lines, helping you build a foundation for efficient and stable production.

1. The "Powerhouse" of Primary Crushing: Jaw Crusher

• Working Principle: Simulating the movement of an animal's jaws, the jaw crusher breaks large materials into smaller particles through cyclical compression and release between the movable and fixed jaws.

• Application: Primary crushing (coarse crushing) in a production line.

• Processed Materials: Highly adaptable, it can handle a variety of hard and medium-hard materials, such as granite, basalt, river pebbles, and iron ore.

• Core Advantages:

◦ Large Crushing Ratio: Large feed opening, capable of handling boulders exceeding 1 meter in diameter.

◦ Simple Structure: Reliable operation, easy maintenance, and low operating costs.

◦ Wide Applicability: The most common and basic coarse crushing equipment in stationary production lines.

II. The "Refiner" of Medium and Fine Crushing: Cone Crusher

• Working Principle: The moving cone rotates within the fixed cone, subjecting the material to continuous compression and bending forces, thus crushing it.

• Applicable Scenarios: Secondary (medium) or tertiary (fine) crushing stages in production lines.

• Processed Materials: Primarily used for crushing high-hardness materials such as granite, basalt, and quartz.

• Core Advantages:

◦ High Production Efficiency: Continuous operation with high production capacity.

◦ Good Finished Particle Shape: Produces uniform stone particles with low needle-like and flaky content.

◦ Wear-resistant and durable: Utilizes a laminated crushing principle, resulting in minimal wear and a long service life.

• Note: Due to its relatively complex structure, investment and maintenance costs are higher than those of a jaw crusher.

III. The "all-rounder" for medium and fine crushing: the impact crusher

• Working Principle: Utilizes a high-speed rotating rotor to impact the material, causing it to gain kinetic energy and then collide with the impact plate for repeated impact crushing.

• Applications: Secondary crushing (medium crushing) in production lines, particularly suitable for materials of medium hardness or below.

• Processed Materials: Limestone, limestone, coal gangue, construction waste, etc.

• Core Advantages:

◦ Excellent particle shape: Utilizing impact crushing, the finished product is mostly cubic with a well-graded structure, making it the preferred choice for high-quality concrete aggregate.

◦ Easy Adjustment: By adjusting the gap between the impact plate and the hammer, the output particle size can be flexibly controlled.

◦ Low Investment Cost: Compared to cone crushers, the initial investment is more advantageous.

• Note: The hammer and impact plate wear out quickly, significantly increasing costs when processing high-hardness materials.

IV. The "Expert" in Sand Making and Shaping: Impact Crusher (Sand Making Machine)

• Working Principle: Utilizes the "stone-on-stone" or "stone-on-iron" principle, allowing materials to collide and rub against each other within the vortex crushing chamber, achieving fine crushing and shaping.

• Applicable Scenarios: The final stage of the production line, used for sand making or aggregate shaping.

• Processed Materials: Suitable for fine crushing and sand making of various rocks.

• Core Advantages:

◦ Excellent Shaping Effect: Produces rounded, continuously graded, and high-quality manufactured sand.

◦ Adjustable Fineness Modulus: The fineness modulus of the finished sand can be easily controlled.

How to Choose the Right Equipment for Your Fixed Production Line?

Choosing crushing equipment is not about choosing the most expensive; the key is "matching." You need to consider the following points:

1. Material Characteristics: Hardness, moisture content, mud content, maximum feed size.

2. Capacity Requirements: How many tons of material need to be processed per hour?

3. Finished Product Requirements: What are the specific requirements for output particle size and shape? (For example, is it for concrete aggregate or roadbed filler?)

4. Investment Budget: Including equipment purchase cost, installation cost, and long-term operation and maintenance cost.

Typical examples of stationary production line equipment configurations:

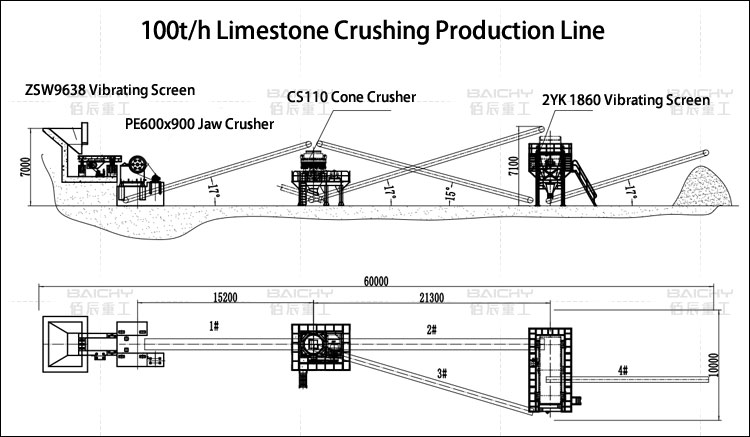

• High-hardness granite production line: Jaw crusher (coarse crushing) + Cone crusher (medium and fine crushing) + Impact crusher (sand making and shaping).

• Medium-hardness limestone production line: Jaw crusher (coarse crushing) + Impact crusher (medium and fine crushing) + Vibrating screen (grading).

A stationary production line is a system engineering project. Crushing equipment is the core, and its selection determines the "genes" of the entire system. A thorough understanding of the working principles and characteristics of various crushers, combined with the specific needs of your project, is essential to making the most scientific and economical decisions, thereby ensuring the long-term stable operation of the production line and creating maximum value.