1. Basic concepts of sand making production line

Sand making production line (Sand Making Production Line) is a complete mechanized production system that is specially used to process various rock raw materials into artificial sand that meets construction standards. Compared with traditional natural sand, artificial sand can accurately control the particle size, particle shape and gradation of sand particles through scientific processing technology to meet the specific needs of different engineering projects.

Modern sand production lines usually have the following characteristics:

• High degree of automation: automatic control of the entire process from feeding to finished product output

• Environmental protection and energy saving: equipped with dust removal and noise reduction system, in line with national environmental protection standards

• Flexible configuration: customized solutions can be made according to raw material characteristics and output requirements

• High quality finished products: the produced machine-made sand has good grain shape and controllable powder content

2. Core equipment composition of sand production line

A complete sand production line usually includes the following key equipment:

• Crushing equipment

Jaw crusher: used for primary coarse crushing of raw materials

Cone crusher/impact crusher: used for medium and fine crushing

Sand making machine (vertical shaft impact crusher): core equipment, realizing the crushing principle of "stone hitting stone" or "stone hitting iron"

• Screening equipment

Vibrating screen: multi-level screens for precise classification =

Air screen: used to control the powder content of finished sand

• Auxiliary equipment

Feeder: evenly and stably transport raw materials

Conveyor: belt conveyor system connecting each process

Dust removal system: collect dust in the production process

Control system: PLC automation control center

3. Typical sand production process

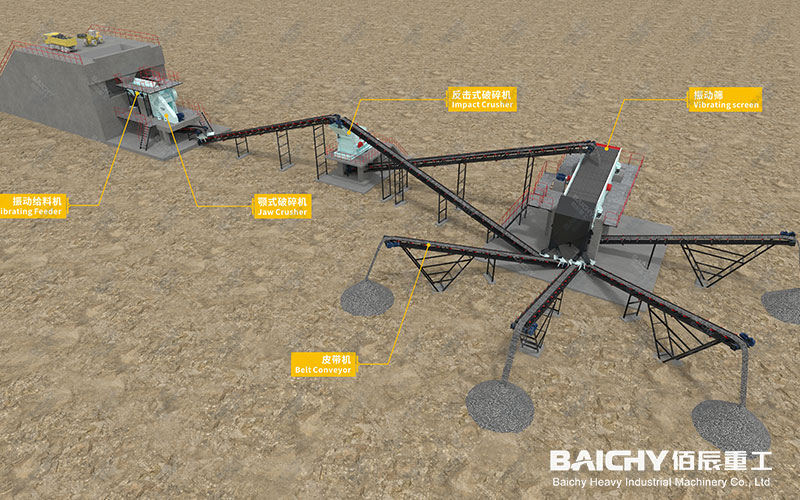

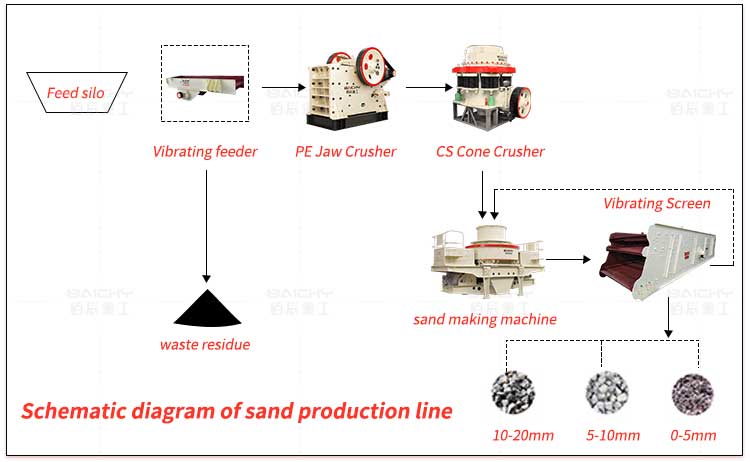

The workflow of a standard sand production line can be divided into five main stages:

• Feeding stage: The vibrating feeder evenly transports the raw materials to the jaw crusher

• Coarse crushing stage: The jaw crusher crushes the large pieces of raw materials into medium particle size

• Medium and fine crushing stage: Cone crusher or impact crusher performs secondary crushing

• Sand shaping: Vertical shaft impact sand making machine processes the ideal particle shape

• Screening and grading: Multi-layer vibrating screens separate products of different specifications

Note: The wet production line will also add a sand washing link to remove impurities and adjust the powder content

4. Application advantages of sand production line

Compared with traditional natural sand, the machine-made sand production line has significant advantages:

Comparison items Machine-made sand production line Natural sand

• Raw material source Various rocks, tailings, etc. River sand, mountain sand

• Quality control Can be precisely controlled Depends on natural conditions

• Environmental protection Dust controllable Damage to riverbed ecology

• Supply stability Stable production throughout the year Restricted by seasons

• Particle shape Can be optimized and adjusted Natural formation

5. Key considerations for purchasing a sand production line

Selecting a suitable sand production line requires considering multiple factors:

• Raw material characteristics: hardness, water content, mud content, etc.

• Output requirements: 50 tons or more than 500 tons per hour

• Finished product requirements: particle size distribution, particle shape standards

• Site conditions: space size, power supply

• Environmental standards: local emission requirements

• Investment budget: equipment purchase and operating costs

It is recommended to consult a professional equipment supplier to obtain a customized production line configuration plan and a detailed return on investment analysis.

With the increasing requirements for the quality of sand and gravel aggregates in the construction industry and the increasing shortage of natural sand resources, modern sand production lines have become the mainstream choice for sand and gravel production. Understanding the composition and principles of the sand production line will help users choose the equipment configuration that best suits their needs and achieve efficient, environmentally friendly and sustainable sand and gravel production.

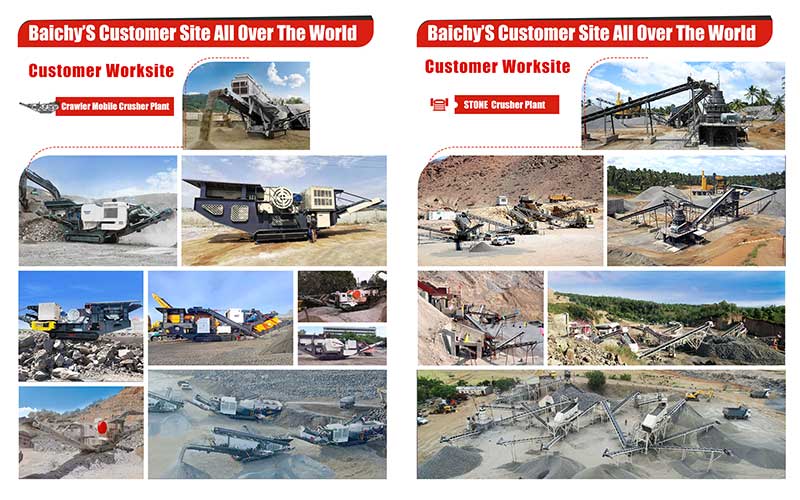

If you need to obtain specific technical parameters or successful case references, please contact a professional sand making equipment supplier for more professional advice.