1. Efficiency and profitability advantages

Recovery rate leads the industry

• Adopting the "pre-waste disposal + flotation enhancement" process, the comprehensive copper recovery rate is ≥88% (measured data of Mexican high-sulfur ore), which is 5%-8% higher than the traditional process.

• Collaborative recovery of associated gold and silver: Through reagent optimization, the recovery rate of gold and silver is simultaneously increased to 65%-75%, and an additional income of 5%-10%.

Stable concentrate quality

• The copper grade of the concentrate is 25%-30% (the standard for the Mexican smelter is ≥20%), and the water content is ≤12%, which directly meets the trade requirements without secondary processing.

2. Cost control advantages

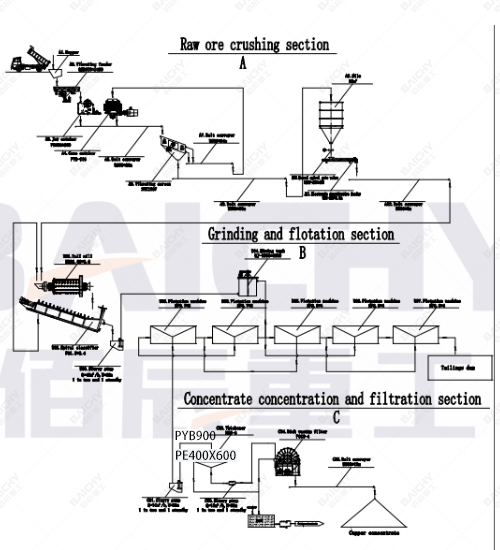

Investment savings

• Equipment selection accurately matches the hardness of Mexican ore (Bond work index 12-15kWh/t), "two-stage crushing + single-stage ball milling" design, saving 25% of infrastructure investment and 35% of energy consumption compared with traditional three-stage crushing.

• Modular layout: supports gradual expansion from 200 tons/day to 500 tons/day to avoid repeated investment.

Operation cost optimization

• Reagent compounding technology (yellow medicine/black medicine + customized inhibitor), reagent cost per ton of ore ≤ US$1.2 (industry average US$1.5-2).

• Tailings dry discharge + water return circulation: water resource utilization rate ≥90%, wastewater treatment cost reduced by 60%

3. Flexibility and reliability

Wide adaptability of ores

• Compatible with sulfide ores (chalcopyrite, bornite) and oxide ores (malachite), and special solutions are designed for complex ores such as high sulfur (S content 15%-30%) and high arsenic (As ≤ 0.5%).

Risk-resistant design

• "Diesel + photovoltaic" hybrid power supply system: to cope with fluctuations in the Mexican power grid, ensuring an annual operating rate of ≥ 95%.

• Intelligent monitoring system: German Siemens PLC control + vibration sensor, real-time warning of equipment abnormalities, reducing the failure rate by 40%.