Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The YGM160 high-pressure grinding mill is an innovative upgrade of the R-type Raymond mill. Its enhanced mainframe structure and unique booster mechanism significantly improve grinding efficiency and fineness control, making it particularly suitable for large-scale production of medium-fine powders ranging from 80 to 425 mesh (up to 500 mesh).

1. High Efficiency and Energy Saving: Its overlapping, multi-stage sealed grinding roller mechanism prevents powder leakage while increasing output by 10-20% compared to traditional Raymond mills at the same fineness level, while also reducing energy consumption.

2. High-Quality Finished Product: The finished product boasts uniform particle shape, a screening rate of up to 99%, and flexible fineness adjustment between 80 and 425 mesh, meeting the fineness requirements of various industries.

3. Wear-Resistant and Durable: The core grinding rollers and grinding rings are made of high-manganese steel or alloy steel, specially treated for exceptional wear resistance and a long service life, effectively reducing maintenance costs.

4. Environmentally friendly and low-noise: The entire system operates under negative pressure and is equipped with a high-efficiency pulse dust collector. Dust emissions fully comply with national environmental standards, ensuring a clean working environment.

5. Stable operation: The smooth transmission system and sturdy construction of key components ensure long-term, continuous operation and a low failure rate.

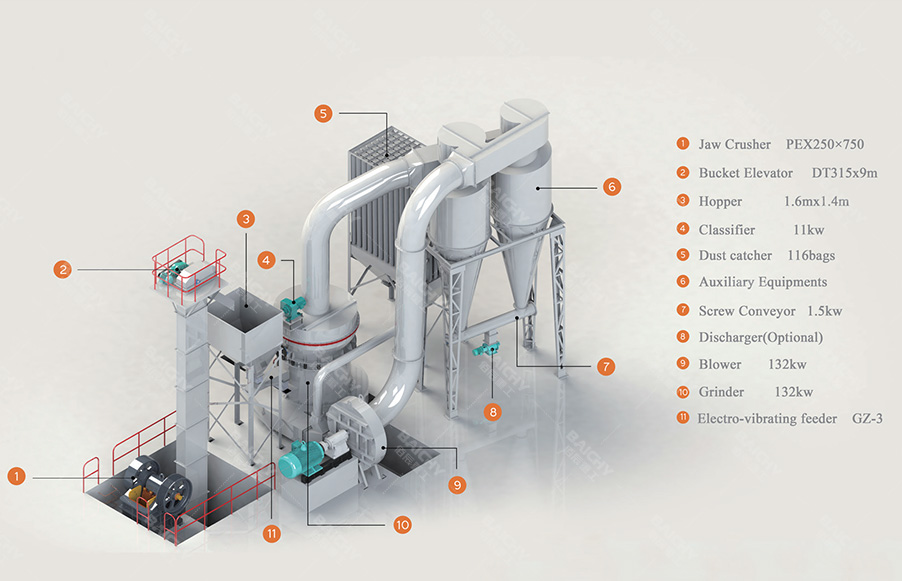

| YGM160 MILL QUOTATION | |||||

|---|---|---|---|---|---|

| Name | Model | Specification | Power (KW) |

Qty (set) |

|

| High pressure suspension roller mill production line | YGM160 | Milling system | Main Grinding Mill | 132 | 1 |

| Classifier | 15 | ||||

| Blower | 132 | ||||

| Cyclone powder collector | / | ||||

| Bag type dust collector | / | ||||

| Connected pipes | / | ||||

| Crusher | Jaw crusher PEX250x750 | 22 | 1 | ||

| Accessory equipment | Bucket elevator T310x9.55m | 4 | 1 | ||

| Transmit hopper Size | / | 1 | |||

| Ele ctro vibrating feeder GZ-4 | 0.45 | 1 | |||

| Electrical cabinet system | Installed power: 305.45 kW | / | 1 | ||

A: The maximum feed size of the YGM160 high-pressure mill is generally ≤30 mm. We recommend crushing the raw materials to a size of 25-30 mm or less to ensure smooth feeding, improve grinding efficiency, and reduce abnormal wear on the grinding rollers and rings.

A: The YGM160's finished product fineness range is typically between 80 mesh and 425 mesh (approximately 0.175 mm to 0.033 mm). Adjustment is very easy, primarily by adjusting the speed of the analyzer (analyzer) above the main unit. The faster the speed, the finer the finished product.

A: The main consumable parts include the grinding roller, grinding ring, and scraper blade. Their service life depends on the abrasiveness of the material being ground. For example, when grinding medium-hard materials such as calcite and limestone, a set of high-quality alloy consumable parts can have a service life of 1-2 years or even longer. However, when grinding high-hardness or highly abrasive materials (such as quartz and zircon sand), the service life is significantly shortened.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.