Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The YGM130 high-pressure grinding mill is a high-efficiency grinding device, an innovation based on the traditional Raymond mill. By enhancing the pressure-applying capacity of the grinding roller assembly, it increases the grinding force exerted by the grinding rollers by 1.2 times, achieving higher output and finer grinding accuracy at the same power. It is particularly suitable for a large number of non-metallic minerals with a Mohs hardness below 9.3.

The YGM130's operating principle can be summarized as "multi-layer grinding, efficient grading."

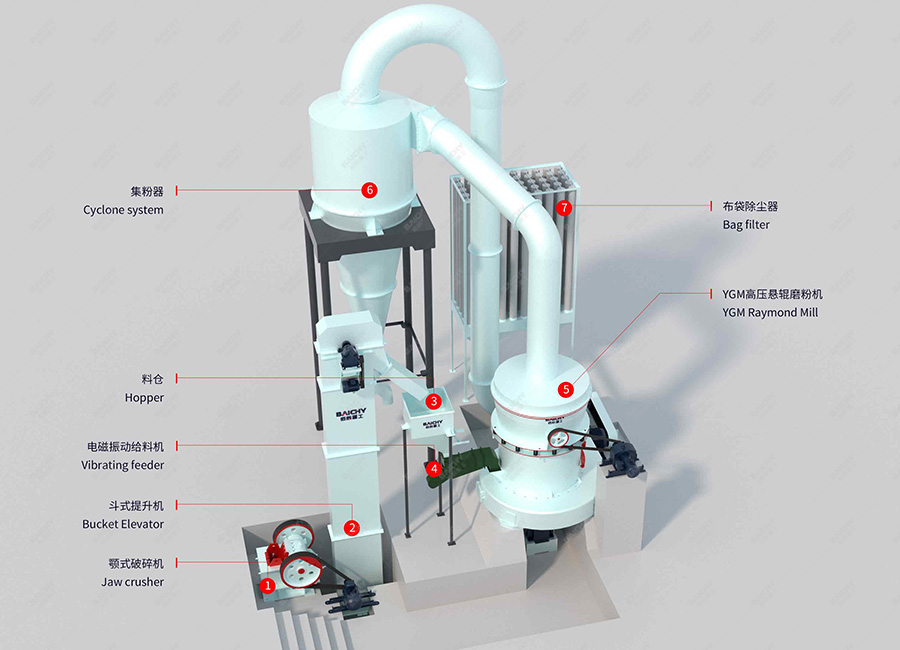

1. Feeding and Grinding: After initial crushing in the jaw crusher, the material is conveyed by an elevator to the storage silo, and then evenly fed into the main grinding chamber via a feeder. Centrifugal force causes the grinding rollers to swing outward, pressing firmly against the grinding rings.

2. High-Pressure Compaction: The core of this process lies in the device's built-in high-pressure spring mechanism. As the grinding rollers compress the material, the springs provide continuous, stable, and intense pressure, firmly compacting the material against the grinding rings for efficient crushing.

3. Analyzer Screening: The crushed powder is lifted by the fan airflow and sent to the analyzer at the top. Unacceptable coarse powder is returned to the analyzer blades for re-grinding, while acceptable fine powder is carried by the airflow into the cyclone collector and ultimately collected as the finished product.

This design ensures a uniform, fine particle size and a high screening rate in the finished product.

| YGM130 MILL QUOTATION | |||

|---|---|---|---|

| Line | Description | Model | Power (KW) |

| 1 | Grinding Mill | YGM130 | Control Cabinet |

| 2 | Fine Jaw Crusher | PE250x400 | 15 |

| 3 | Hopper | 1.5 | |

| 4 | Bucket Elevator | TH200x6.5 | 3 |

| 5 | Belt Feeder With VFD | B500x4M | 3 |

| 6 | Main Unit | — | 110 |

| Classifier | 22 | ||

| Blower | 90 | ||

| Cyclone Collector With Connect Pipes |

0 | ||

| Discharge value | 1.5 | ||

| Bag Filter | |||

| 7 | Control Cabinet | 0 | |

A: Equipment prices vary depending on configuration, after-sales service, and other factors; there is no fixed price. Please provide your specific material, output, and fineness requirements, and we will provide you with the most accurate quote.

A: Absolutely. The YGM130 is designed for a hardness upper limit of 9.3, making it capable of handling materials with a hardness of 7. However, it is recommended that grinding rollers and rings be made of highly wear-resistant materials to extend their service life.

A: We provide turnkey services, from foundation drawings and equipment installation instructions to worker training, to ensure smooth commissioning.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.