Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

As core grinding equipment in modern industry, vertical coal mills play a dual role in the energy, building materials, metallurgy, and other fields:

Due to its superior performance, the vertical coal mill has become an ideal alternative to traditional ball mills and is hailed as the "heart" of coal pulverization systems in modern large-scale production lines.

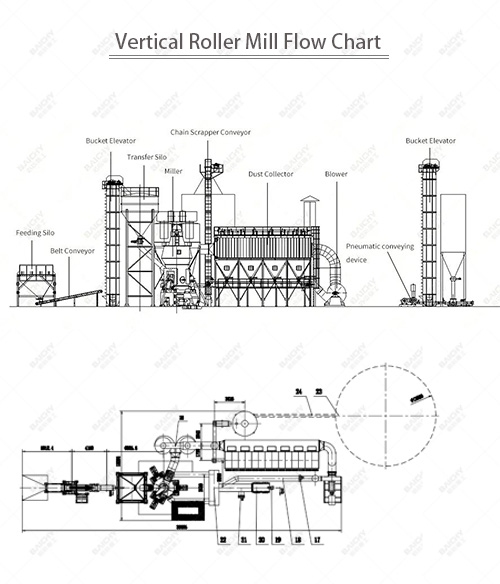

The core of the mill lies in its unique "crushing and drying" process. Raw coal is fed from the top of the mill and lands on the center of the rotating grinding disc. Centrifugal force moves it between the grinding disc and the grinding rollers. A hydraulic system drives the grinding rollers to apply pressure, crushing the coal. Simultaneously, hot air introduced from the bottom lifts the pulverized coal, efficiently drying it within the chamber before sending it to the top separator for sorting. Fine coal of acceptable fineness is transported by the airflow into the collection system, while coarse coal falls back to the grinding disc for further grinding.

This operating principle results in significant energy efficiency: concentrated force is applied to the material, resulting in high energy utilization, and the integrated drying function significantly improves the overall energy efficiency of the system.

1. High efficiency and energy saving, low operating costs:Vertical coal mills utilize the material bed grinding principle, resulting in high energy efficiency and saving 20%–30% compared to traditional ball mills, making them truly energy-efficient coal mills.

2. Compact structure and small footprint:The vertical layout offers high integration, effectively reducing plant floor space and lowering construction investment.

3. Low noise and environmental friendliness:The equipment operates smoothly, with significantly lower noise levels than ball mills. The system utilizes a fully enclosed negative pressure system, effectively controlling dust emissions and improving the working environment.

4. Strong drying capacity and wide adaptability:High-temperature flue gas can be introduced to simultaneously dry and grind high-moisture raw coal. The resulting powder fineness is stable and uniform, facilitating smooth control of the subsequent combustion process.

Vertical coal mills are highly efficient and energy-efficient grinding equipment widely used in various fields, primarily for grinding lump or granular materials into fine powder.

1. Power Industry: Pulverized Coal Boiler Systems

In thermal power plants, vertical coal mills are used to grind raw coal into pulverized coal for efficient combustion in boilers, directly impacting power generation efficiency and stability.

2. Building Materials Industry: Cement Production Lines

Preparing pulverized coal for cement rotary kilns and precalciners provides a stable heat source, particularly suitable for processing high-humidity coal, contributing to energy savings and consumption reduction.

3. Metallurgical Industry: Blast Furnace Coal Injection Systems

Producing pulverized coal that meets blast furnace injection requirements, replacing some coke and reducing ironmaking costs, is a key component of green smelting.

Mainly includes bituminous coal, anthracite, and other coal types, suitable for pulverizing coal in industries such as power, building materials, and metallurgy.

| Model | Grinding table dia.(mm) | Max feeding size(mm) | Discharge size(um) | Discharge size(mesh) | Air-in tempreture(℃) | Air-out tempreture(℃) | Input material moisture | Final moisture | Capacity(t/h) | Motor Power(kw) |

|---|---|---|---|---|---|---|---|---|---|---|

| SRM1300 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 10-35 | 185-250 |

| SRM1500 | 1500 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 13-48 | 250-355 |

| SRM1700 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 18-68 | 355-600 |

| SRM1900 | 1900 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 23-85 | 450-600 |

| SRM2200 | 2200 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 36-135 | 710-1000 |

The main advantages are:

Low energy consumption: Utilizing the material bed grinding principle, it offers high energy efficiency and saves approximately 20%-30% more electricity than a ball mill.

Small footprint: The vertical mill's compact structure occupies approximately 50%-70% of the floor space of a ball mill.

Low noise: Operating noise is typically below 80 decibels, creating a better working environment.

Strong drying capacity: Hot air can be introduced, allowing it to process materials with high moisture content (up to 15%-20%).

Easy product fineness adjustment: Product fineness can be quickly adjusted by adjusting the classifier speed.

This is primarily achieved by adjusting the classifier speed. Higher speeds increase the centrifugal force, allowing only finer particles to be carried away by the airflow, resulting in a finer product. Conversely, lower speeds result in a coarser product. The adjustment process is simple, flexible and fast.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.