How to choose the right aggregate crusher?

Selecting the optimal crusher requires a comprehensive evaluation of several key factors to ensure it meets your operational and economic goals. Primary considerations include:

1. Material properties: including hardness, wear resistance, moisture content, and feed size.

2. Capacity requirements: Determine the equipment's processing capacity based on the scale of production.

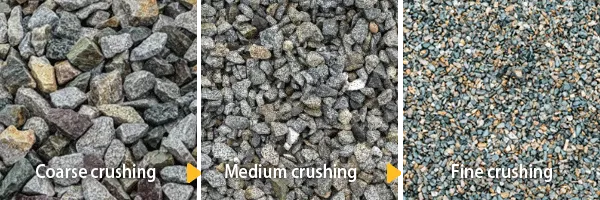

3. Product requirements: Required particle size and shape of the finished product.

4. Investment budget: Balance between equipment purchase and operating costs.

5. Environmental requirements: Dust and noise control standards.

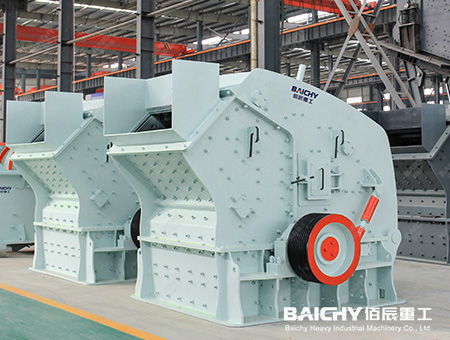

As core equipment in building material production, the performance of the aggregate crusher directly impacts aggregate quality and production costs. With technological advancements, modern crushing equipment is becoming more efficient, intelligent, and environmentally friendly. Selecting the right crusher and properly operating and maintaining it are crucial for improving production efficiency and reducing operating costs.

When selecting equipment, it is recommended to consult with professional technicians based on actual production needs and conduct a comprehensive evaluation before making a decision.