How to choose a suitable concrete crusher?

When purchasing a concrete crusher, the following factors need to be considered:

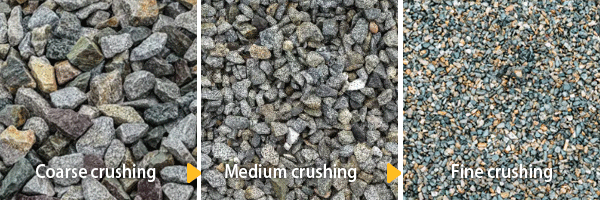

1. Crushing requirements: feed size, output requirements (tons/hour), and finished product particle size.

2. Equipment performance: motor power, wear-resistant parts material (such as high manganese steel jaw plate), and hydraulic system stability.

3. Use environment: fixed (suitable for long-term production) or mobile (suitable for temporary projects).

4. Budget and brand: Different brands have large price differences. It is recommended to compare multiple manufacturers and pay attention to after-sales service.

Concrete crushers play an important role in construction waste treatment and recycled aggregate production. Choosing the right equipment can not only improve production efficiency but also reduce costs. I hope this article can help you understand the characteristics and prices of different types of crushers and make wise purchasing decisions.

If you want to learn more or get exclusive solutions, please contact us!