Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

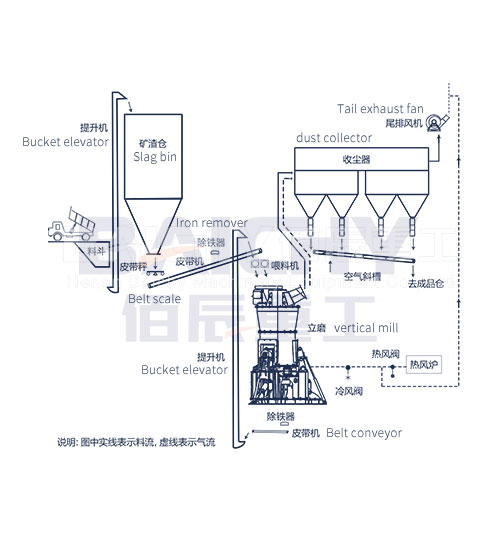

A slag vertical mill is a vertical roller mill designed specifically for processing industrial solid waste such as steel slag. It integrates crushing, grinding, drying, and powder selection, offering significant advantages over traditional ball mills when processing hard, abrasive steel slag.

1. High-Efficiency Grinding: Utilizing the material bed grinding principle, it achieves high energy efficiency and grinding efficiency far exceeding that of traditional equipment.

2. Energy Saving and Consumption Reduction: System power consumption can be reduced by 30%-50%, significantly lowering production costs.

3. High-Quality Finished Product: Steel slag can be easily ground into active micropowder with a specific surface area of ≥420 m²/kg or even higher, resulting in a highly active and stable product.

The product of the slag vertical mill—fine slag powder—is the key to achieving value transformation.

1. In the Cement Industry: As a cement admixture, it can effectively improve cement performance and reduce cement production costs.

2. In the Concrete Industry: As a concrete admixture, it can significantly enhance concrete's durability, strength, and workability, while reducing cement usage and achieving green production.

Our steel slag vertical mill system is trusted by major steel companies and grinding plants worldwide. It efficiently transforms steel slag from industrial waste into a valuable green raw material for the concrete and cement industries, delivering both environmental and economic benefits.

Why choose our system? Backed by deep expertise in solid waste processing, we offer:

Optimized for abrasive steel slag, our mill features extended-wear components and can be tailored to your specific material and capacity needs.

Designed for reliable, low-noise performance with integrated dust removal, ensuring emissions stay well below national standards for clean production.

Benefit from significant energy savings and product value enhancement, leading to a quick return on investment and long-term profitability.

| Model | Grinding table dia.(mm) | Max feeding size(mm) | Discharge size(um) | Discharge size(mesh) | Air-in tempreture(℃) | Air-out tempreture(℃) | Input material moisture | Final moisture | Capacity(t/h) | Motor Power(kw) |

|---|---|---|---|---|---|---|---|---|---|---|

| SRM1300 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 10-35 | 185-250 |

| SRM1500 | 1500 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 13-48 | 250-355 |

| SRM1700 | 1300 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 18-68 | 355-600 |

| SRM1900 | 1900 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 23-85 | 450-600 |

| SRM2200 | 2200 | ≤38 | 212-45 | 70-325 | ≤350 | 70-95 | 4-15% | ≤1% | 36-135 | 710-1000 |

A: The principles of the two are similar, but not entirely interchangeable. The main differences are:

Material Properties: Steel slag contains a small amount of metallic iron, making it more abrasive, and its composition and grindability fluctuate more.

Equipment Design: Steel slag vertical mills utilize special materials and designs for wear-resistant components such as roller sleeves and liners that are more resistant to impact and wear. The internal classifier and iron removal device are also optimized to address the characteristics of steel slag.

Conclusion: While slag vertical mills can process some easily grinded steel slag, to ensure long-term stable operation, high efficiency, and low maintenance costs, it is strongly recommended to use a vertical mill specifically designed for steel slag.

A: Modern steel slag vertical mills have excellent grinding capabilities. By adjusting parameters such as the classifier speed, the fineness of the finished product can be flexibly controlled. Typically, the finished product surface area can consistently reach above 420-450 m²/kg, and even 500-600 m²/kg or finer, to meet the requirements of different cement grades and concrete admixtures.

A: The steel slag vertical mill is highly efficient, energy-efficient, and environmentally friendly.

Low Energy Consumption: Utilizing the material bed grinding principle, it achieves high energy efficiency and low system power consumption.

Environmentally Compliant: The entire system operates under negative pressure, features fully enclosed conveying, and is equipped with a high-efficiency pulse bag dust collector. Dust emission concentrations are far below national environmental standards (typically below 20 mg/Nm³).

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.