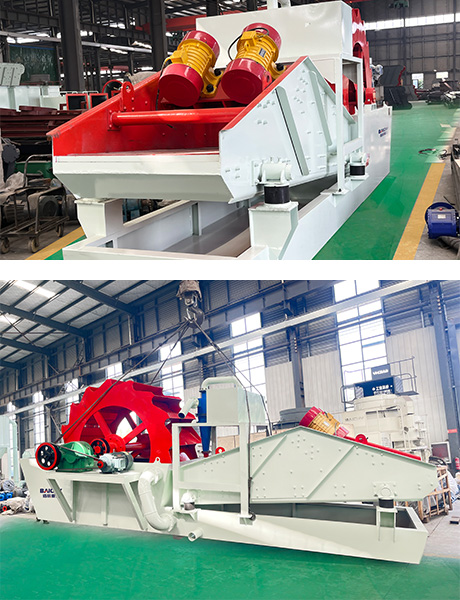

The integrated sand washing and dewatering machine is a highly efficient integrated solution for modern sand and gravel production lines. It innovatively combines three major functional modules: wheel bucket washing, high-frequency dewatering screening, and fine sand recovery, achieving a single-machine assembly line operation of "feeding-washing-dewatering-discharging".

This single machine handles washing, dewatering, and recycling, providing an efficient and integrated solution for producing high-quality, high-value finished sand.

1. Highly integrated, efficient and cost-effective

2. High-quality finished products, significantly increased value

3. Fine sand recovery, increased production and environmental protection

The wheel bucket sand washing machine is a classic, sturdy, and durable cleaning equipment for coarse granular materials. Its working principle is that the impeller rotates in the water tank, driving the sand and gravel materials to tumble and rub against each other, thereby powerfully removing mud and impurities from their surfaces. The transmission part of this equipment is isolated from water and sand, resulting in a low failure rate and easy maintenance. It is especially suitable for cleaning medium and coarse aggregates such as stones, pebbles, and river gravel.

With its robust structure and strong washing capabilities, it is the classic and durable workhorse equipment for cleaning coarse materials such as stones and pebbles.

1. Robust structure, durable and long-lasting

2. Strong washing power, high cleanliness

3. Large processing capacity, easy maintenance

The spiral sand washing machine is a device that combines cleaning and rough grading functions. During operation, the material is driven by rotating spiral blades in an inclined tank. Through continuous scrubbing and upward lifting, it completes cleaning and preliminary separation according to particle size. This equipment has a good effect on retaining fine sand, with a low flushing loss rate and stable and reliable operation.

It performs gentle washing while simultaneously carrying out rough classification, making it a practical model for applications requiring high retention of fine sand and stable operation.

1. Washing and grading, one machine for two purposes

2. Fine sand retention, low loss rate

3. Stable operation, strong adaptability

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Core Selection Logic: Based on your "core raw materials" and "core objectives."

• Core Raw Materials: Primarily manufactured sand, crushed sand (0-5mm), or fine-grained materials with high clay and powder content.

• Core Objectives: Seeking high added value for finished sand, requiring clean and dry sand (low moisture content) that can be directly sold as commercial sand, and aiming to reduce fine sand loss, save production line space, and reduce construction costs.

Recommendation: Choose this if you want to sell high-priced commercial sand. This is a modern upgrade option for improving sand quality and profitability.

• Core Raw Materials: Primarily stones, pebbles, crushed stone, slag, and other medium to coarse-grained aggregates (above 5mm).

• Core Objectives: To powerfully remove dirt and impurities attached to the surface of aggregates, meeting the cleanliness requirements for concrete aggregates or building materials, and requiring robust, durable equipment with low operating costs.

Recommendation: Choose this for washing stones and pebbles. This is a time-tested "tough guy" equipment in the field of coarse aggregate cleaning.

• Core Raw Materials: Natural sand, mountain sand with low clay content, or materials where maintaining the gradation (ratio of coarse to fine sand) is required.

• Core Objectives: To gently wash while maximizing the retention of effective fine sand, or requiring simple particle size classification. The dryness of the finished sand is not a high priority.

Recommendation: Choose this if you want to retain fine sand and maintain gradation. This is a practical equipment focusing on sand retention rate and stable operation.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!