Limestone Crushing Solutions

Limestone, a core raw material in industries such as construction, metallurgy, and environmental protection, directly impacts the operational efficiency of production lines due to its crushing efficiency and finished product quality. However, rapid equipment wear, high energy consumption, and substandard finished product particle shape have long plagued many production enterprises. This article will systematically introduce a highly efficient and energy-saving crushing solution to help you significantly reduce overall costs and enhance market competitiveness.

As a quarry operator, production line manager, or project decision-maker, do you frequently face the following challenges?

• Severe equipment wear, frequent replacement of vulnerable parts such as hammers and impact plates, resulting in high maintenance costs;

• Continuously rising electricity costs, high energy consumption of traditional crushers, and difficulty in controlling power consumption per ton;

• Poor finished product particle shape, with excessive needle-like and flaky content, affecting product selling price and market application;

• Complex production line debugging, insufficient equipment stability, and frequent shutdowns impacting overall output;

• Increasing environmental pressure, with dust and noise control failing to meet green production requirements.

Solution Introduction: Rock Solid II High-Efficiency Cone Crusher Solution

Addressing the aforementioned pain points, we introduce the Rock Solid II high-efficiency hydraulic cone crusher solution. This solution combines the principle of layered crushing with an intelligent hydraulic control system to systematically achieve high efficiency, low consumption, and stable operation in the crushing process, significantly extending the life of wear-resistant parts and precisely controlling the particle size of the finished product.

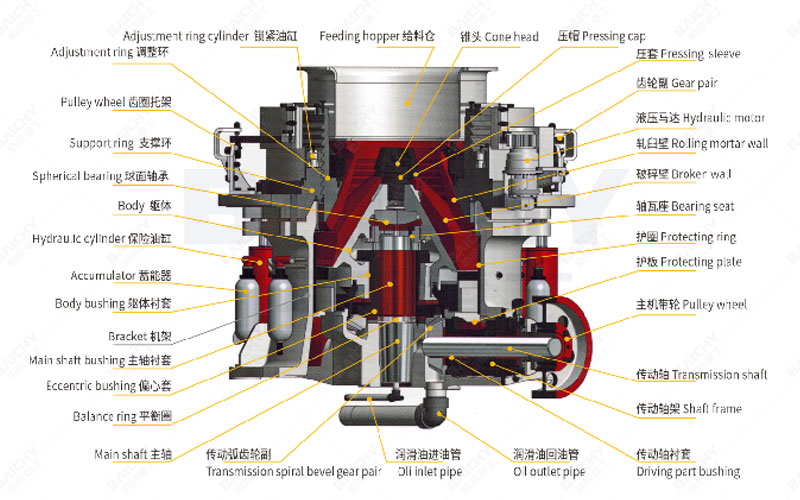

Structural diagram of a hydraulic cone crusher

Working Principle Explanation

The hydraulic cone crusher employs the principle of layered crushing, where materials are subjected to multi-dimensional compression and impact within the crushing chamber, rather than single-impact crushing. By adjusting the discharge port and crushing force in real time through the hydraulic system, it achieves a stone-on-stone self-crushing effect while avoiding over-crushing, thereby improving the yield and reducing ineffective energy consumption.

Key features include:

• A hydraulic adjustment and overload protection system for precise discharge port control and automatic foreign object removal;

• A large-diameter crushing spindle and heavy-duty frame design ensure stability under high load operation;

• Modular wear-resistant parts design supports online replacement of key components, reducing maintenance time;

• An intelligent control unit monitors spindle position, motor load, and other parameters in real time, enabling unmanned adjustment.

Core Advantages and Value

| Features | Actual Value Received |

| 40% Increase in Wear Part Life | Reduces spare parts procurement frequency, annual maintenance costs decrease by over 20% |

| Approximately 25% Reduction in Unit Power Consumption | Estimated annual electricity savings of over 150,000 RMB for a 300,000-ton-per-year production line |

| Finished Product Qualification Rate ≥95% | Uniform Particle Shape, High Cubic Proportion, Increased Product Premium |

| Intelligent Operation and Maintenance System Support | Real-time equipment status diagnosis, reduced unexpected downtime, improved capacity utilization |

Successful Cases/Application Scenarios

A large cement group's 2 million-ton-per-year limestone production line previously used a traditional jaw crusher + impact crusher solution, resulting in high equipment failure rates and a finished product needle-like/flaky content of 18%. After switching to the Rock Solid II solution:

• Average hourly output increased from 180 tons to 240 tons;

• Expanded crushing ratio adjustment range, one solution simultaneously meets multiple particle size requirements;

• Increased replacement cycle for wear parts from 450 hours to 750 hours;

• Annual comprehensive cost savings exceeding 800,000 RMB.

How to Choose and Matching Recommendations?

When selecting a solution, the following factors should be considered:

1. Raw material characteristics: feed particle size, moisture content, silicon content;

2. Production capacity requirements: Select the model based on current output and future expansion potential;

3. Finished product application: Different applications, such as aggregates, cement raw materials, or desulfurizers, correspond to different particle size requirements;

4. System matching recommendations: It is recommended to match with a high-efficiency vibrating feeder and a circular vibrating screen to form a closed-loop cycle, further improving overall efficiency.

Frequently Asked Questions (FAQ)

1. Is this solution suitable for high-silicon limestone?

The key components of the hydraulic cone crusher use high-chromium alloy steel wear-resistant parts, suitable for materials with a Mohs hardness ≤7. For high-silicon raw materials, we provide customized wear-resistant solutions to ensure equipment lifespan and stability.

2. What are the requirements for foundation construction for equipment installation?

The equipment offers two options: steel structure foundation and concrete foundation. If site conditions are limited, our company can provide an integrated steel frame base, shortening the installation cycle and reducing civil engineering costs.

3. Does it support remote monitoring and intelligent operation and maintenance?

Yes. The solution comes standard with a data acquisition module, which can monitor operating data in real time through a cloud platform, predict component lifespan, and provide fault warnings and handling suggestions.

Limestone crushing is not only a competition of output, but also a competition of efficiency. Hydraulic cone crusher solutions, with their long-term stability and economic reliability, have become the preferred upgrade choice for many enterprises. If you would like to obtain a customized production line assessment report or schedule an on-site trial, please contact our technical consultant immediately. We will provide you with customized solutions and full-cycle service support!

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!