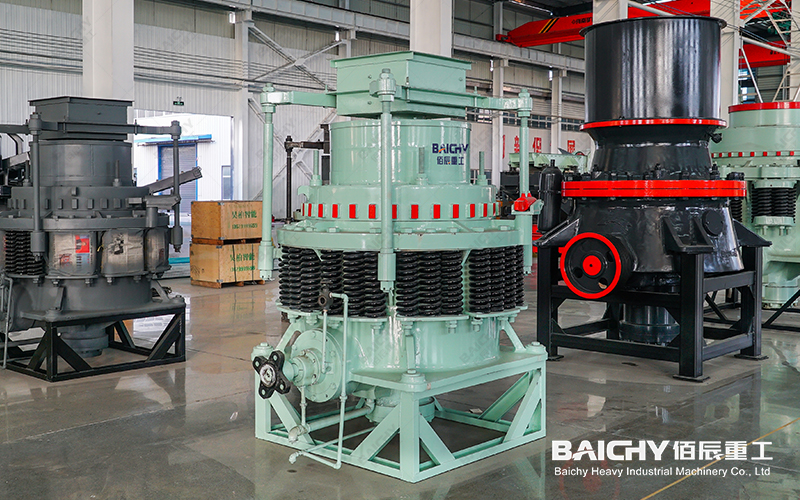

Symons 4.25 Ft Cone Crusher

In the field of mining crushing, Symons cone crushers, with their classic design and reliable performance, have withstood decades of market testing and are still hailed as the epitome of standard cone crushers. Among them, the Symons 4.25-foot cone crusher plays an indispensable role in medium-sized crushing operations. This article will provide an in-depth analysis of the performance and advantages of this equipment, and why it has become the core choice for many mobile crushing plant projects.

Equipment Overview and Technical Analysis

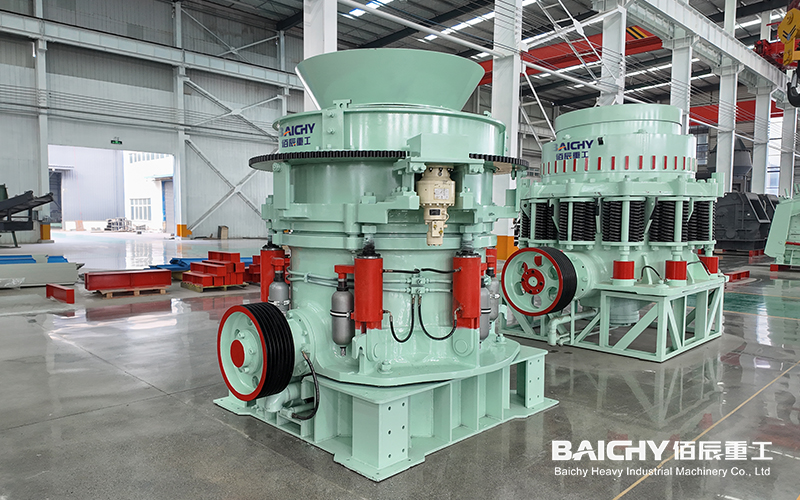

The Symons 4.25-foot cone crusher belongs to the spring cone crusher series. Its core working principle is that a motor drives a horizontal shaft to rotate, and through gear transmission, an eccentric sleeve drives the moving cone to oscillate in a circular motion, thereby achieving compression and impact crushing of materials. Its 4.25-foot specification mainly refers to the diameter of the bottom of the moving cone, which determines its processing capacity and maximum feed size.

This equipment is particularly suitable for secondary medium crushing and tertiary fine crushing. Compared to hydraulic cone crushers, Symons cone crushers have a more classic structure and mature maintenance procedures, making them a highly attractive option for customers seeking long-term stable operation and overall cost-effectiveness. They can effectively process high-hardness materials such as granite, basalt, and quartz.

Symons 4.25 Ft Cone Crusher

Key Advantages of the Symons 4.25-foot Cone Crusher

1. Superior Reliability and Durability

Symons equipment is renowned for its robust construction and simple mechanical design. Key components such as the bowl-shaped crusher and crushing wall are made of high-manganese steel, offering high wear resistance and a long service life. Its spring safety device automatically releases when uncrushable foreign objects such as iron enter the chamber, effectively protecting the main unit from damage and ensuring the Symons cone crusher's exceptional reliability under harsh operating conditions.

2. Excellent Finished Particle Shape and Size

Utilizing the principle of layered crushing, the material undergoes multiple compressions and impacts within the crushing chamber formed by the crushing wall and the jaw wall, resulting in a finished product with low flaky content, high cubic particle count, and uniform particle shape. This is crucial for the aggregate quality required for commercial concrete batching plants and high-grade highway construction. By adjusting the discharge port, the output particle size can be easily controlled to meet the needs of different customers.

3. Convenient Maintenance and Low Operating Costs

Standardized parts make replacement and maintenance simple and quick. The symmetrical design of the machine structure allows for reorientation after wear, extending the service life of vulnerable parts. For manufacturers of mobile crushing equipment for mining, integrating this long-maintenance, easy-to-operate equipment into mobile crushing stations can greatly improve end-customer equipment uptime and satisfaction.

Successful Application Cases

We provided a complete mobile crushing and screening station for a large granite quarry in East China, using a Symons 4.25-foot cone crusher as the core secondary crushing unit. This production line has a stable processing capacity of 150-200 tons per hour, further crushing primary materials with a particle size of approximately 100mm to below 30mm. The equipment has operated continuously for over 8000 hours without major overhaul. Its stable performance and excellent finished product quality have helped customers win aggregate supply contracts for several major infrastructure projects in the surrounding area, with a return on investment far exceeding expectations.

Recommended Equipment

To maximize the efficiency of the Symons 4.25ft cone crusher, we recommend using it in conjunction with the following equipment:

• Primary Crushing Equipment: Jaw crusher (e.g., PE600×900) for initial crushing of large ore blocks.

• Feeding and Screening Equipment: Heavy-duty vibrating feeder, circular vibrating screen, or linear vibrating screen, forming a closed-loop system.

• Mobile Platform: Wheeled or tracked mobile platform chassis for rapid relocation and flexible deployment of the equipment.

Frequently Asked Questions (FAQ)

What is the maximum feed size for the Symons 4.25ft cone crusher?

Typically, the maximum permissible feed size for the Symons 4.25ft cone crusher is approximately 150mm. However, the actual feed size needs to be fine-tuned based on the selected chamber type and the hardness and moisture content of the material to achieve optimal production efficiency and liner lifespan.

Can it be used to crush wet, sticky materials?

For materials with high moisture content and high viscosity, directly using a standard Symons cone crusher may pose a risk of clogging the crushing chamber. We recommend pre-screening or dewatering the raw material before feeding, or considering a specially designed chamber type during selection to ensure continuous production.

What is the approximate power consumption of this equipment?

The motor power for a Symons 4.25-foot cone crusher typically ranges from 110kW to 160kW, depending on the material hardness, required output, and discharge particle size. Our engineers will provide detailed power configuration recommendations for each customer.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!