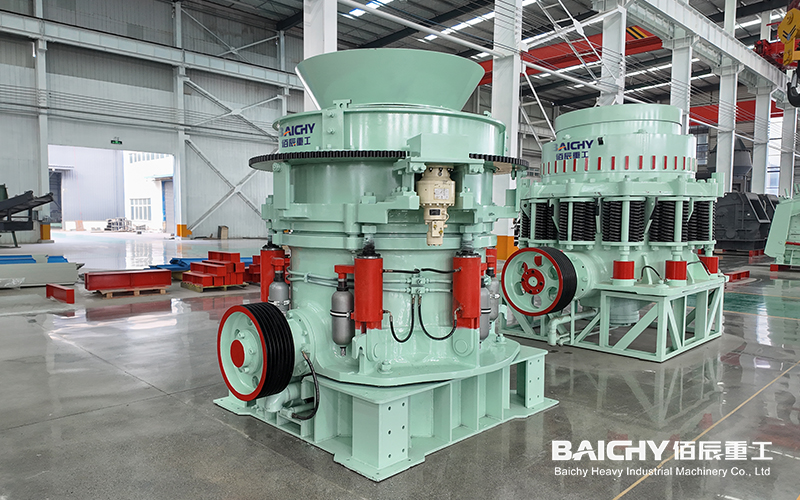

Stone Cone Crusher - Durable

Stone cone crushers are core equipment in mining crushing operations, excelling especially in processing high-hardness stones. Durable stone cone crushers are designed for high-intensity, continuous operation, possessing excellent wear resistance and stability, significantly reducing equipment failure rates and improving production efficiency. As a manufacturer of mobile crushing equipment for mining, we are committed to providing customers with reliable and durable crushing solutions.

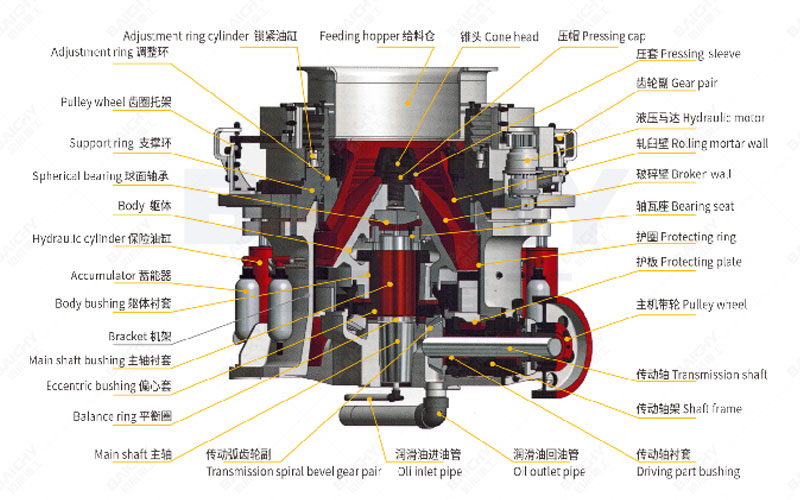

Stone Cone Crusher Structural Design and Working Principle

Cone fracture structure diagram

The stone cone crusher uses a motor to drive an eccentric sleeve to rotate, causing the moving cone to oscillate, forming a crushing chamber between it and the fixed cone. Within the chamber, the stone is subjected to compression, impact, and bending, achieving multi-stage crushing. Its hydraulic system can adjust the discharge opening size in real time, controlling the output particle size and ensuring uniform crushing results.

Core Advantages of Durable Stone Cone Crusher:

1. High-Strength Materials and Wear-Resistant Design:

Key components (such as the moving and fixed cones) are made of high-manganese steel or alloy steel castings, with a hard alloy liner covering the surface, increasing impact resistance by more than 50% and extending service life by 30% compared to ordinary models.

2. Intelligent Hydraulic System

Equipped with an overload protection device, it automatically releases pressure when encountering uncrushable objects to prevent equipment damage. The lubrication system features circulating filtration to reduce component wear.

3. Modular Structure

Main modules support rapid replacement, reducing downtime. For example, liner replacement takes only 4-8 hours, increasing efficiency by 40% compared to traditional equipment.

Real-world Application Case

Project Background: A granite quarry requires a daily processing capacity of 3000 tons, with stone compressive strength exceeding 180MPa.

Solution: Configure two durable stone cone crushers, employing a layered crushing process, with an output particle size adjustment range of 20-45mm.

Results: The equipment operated continuously for 12 months without major repairs, with a failure rate of less than 2%. The needle-like and flaky content of the finished aggregate was controlled within 8%, meeting high-speed rail construction standards.

Recommended Supporting Equipment

1. Feeder: Vibrating feeder ensures uniform feeding and avoids clogging of the crushing chamber.

2. Screening System: Multi-layer circular vibrating screen forms a closed-loop circulation with the cone crusher, improving the finished product yield.

3. Mobile Chassis: Can carry the crusher for flexible relocation, suitable for mines with multiple mining areas.

Frequently Asked Questions (FAQ)

Q1: Is the durable stone cone crusher suitable for processing basalt?

Yes. Its high-chromium alloy hammers and hydraulic protection design can handle the high abrasiveness of basalt. It is recommended to control the feed particle size to ≤200mm.

Q2: What is the equipment maintenance cycle?

The lubrication system needs to be checked every 500 hours. The liners should be replaced immediately when wear exceeds 70%. Under normal operation, the overhaul cycle is 3-5 years.

Q3: How to control the finished product particle size?

By hydraulically adjusting the discharge port or replacing different cavity liner types, for example, the standard cavity is used for medium crushing, and the short head cavity is used for fine crushing.

The durable stone cone crusher is an ideal choice for hard rock crushing due to its long service life and low operating costs. By combining intelligent control systems with modular design, it helps mines reduce costs and increase efficiency.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!