Primary Crushing Solutions

In mining operations, primary crushing is the cornerstone and starting point of the entire production process. Its efficiency and stability directly determine the capacity and cost of subsequent medium and fine crushing, and even the entire production line. This article will delve into what primary crushing solutions are, particularly how modern mobile crushing equipment can revolutionize traditional stationary production lines, bringing unprecedented flexibility and economic benefits to mine owners.

| Key Words | Primary Crushing Solutions |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤1200mm |

| Motor Power | 15-280kw |

| Capacity | 5-1100t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

What is Primary Crushing? Overview and Core Objectives

1. Core Definition of Primary Crushing

Primary crushing, also known as primary crushing, refers to the process of first-stage crushing of the large raw stones obtained after blasting in the stope. These raw stones are enormous, potentially exceeding 1 meter in size. The goal of primary crushing solutions is to crush these boulders to a size suitable for secondary crushing, typically below 200-300 mm.

2. Key Role of Primary Crushing

The core role of this stage lies in volume reduction and pre-processing. It sets the tone for the entire crushing process:

• Preparing for subsequent crushing: Crushing the raw material to a size suitable for the feed inlet of medium crushing equipment (such as cone crushers and jaw crushers).

• Improved overall production line efficiency: A stable supply of primary crushing material is fundamental to ensuring the full-load and efficient operation of subsequent equipment.

• Reduced overall costs: Highly efficient primary crushing significantly reduces energy consumption and equipment wear during transportation and secondary crushing.

Brazilian mobile crushing plant granite crushing site

Significant Advantages of Mobile Primary Crushing Solutions

Compared to traditional stationary production lines, using mobile crushing equipment for primary crushing brings revolutionary changes.

1. Unparalleled Flexibility and Convenience

The biggest advantage of mobile crushing equipment lies in its mobility. The equipment can drive itself into the work site without the need for piling and fixing, allowing it to closely follow the progress of the mining face, greatly reducing the transportation distance of stone between the quarry and the crushing station, saving significant truck transportation costs.

2. Rapid Deployment and Low Installation Costs

Traditional stationary crushing stations require complex foundation construction, such as concrete foundations and steel frame structures, which can take weeks or even months. Mobile crushing stations, on the other hand, require minimal on-site preparation and can be deployed and put into production within days, significantly reducing upfront investment and installation time costs.

3. Strong Adaptability and Environmental Friendliness

For mines with complex terrain and dispersed working faces, mobile crushing solutions can easily handle the challenges. Simultaneously, the crush as you mine model reduces dust and exhaust emissions from truck transportation, better meeting the environmental requirements of modern green mines.

Success Story: Primary Crushing Practice in a Large Brazilian Granite Mine

Client Background: A large granite mine in Brazil previously used the traditional blasting-truck transportation-fixed jaw crusher model, resulting in high transportation costs and significant efficiency bottlenecks.

Solution: We recommended and configured a tracked mobile jaw crusher station as the core equipment of our primary crushing solution. This equipment is deployed directly at the mining face.

Results:

• 40% Reduction in Transportation Costs: With the mobile station operating at the forefront, the distance for ore truck transportation was reduced by over 60%.

• 25% Increase in Production Efficiency: Reduced waiting time and long-distance transportation time enhanced production line continuity.

• Fast Return on Investment: Due to low installation costs and rapid efficiency improvements, the equipment recouped its investment in a short period.

Recommended for you: Our Primary Crushing Core Equipment

We offer a variety of mobile crushing equipment options to suit different raw material characteristics and capacity requirements:

1. Tracked Mobile Jaw Crusher: Robust and durable, with strong crushing force, it is an ideal choice for primary crushing, especially suitable for processing hard rock.

2. Wheeled Mobile Jaw Crusher: Flexible and easy to relocate, suitable for working conditions where the operation point is relatively fixed but requires intermittent relocation.

3. Mobile Heavy-Duty Feeder + Jaw Crusher Combination: For raw materials with high soil content and prone to clogging, a pre-installed heavy-duty screen separates the soil in advance, ensuring efficient operation of the jaw crusher.

Frequently Asked Questions (FAQ) about Primary Crushing Solutions

1: Is the crushing capacity of mobile primary crushing plants insufficient compared to stationary ones?

A: This is a common misconception. Modern high-performance mobile crushing equipment uses the same or even better technology and materials as stationary equipment for its core crusher (such as a deep-cavity jaw crusher), fully meeting the primary crushing capacity requirements of most mines. Some models can achieve an hourly capacity of thousands of tons.

2: Is maintenance of mobile equipment more complex?

A: Quite the opposite. Our mobile crushing equipment features a modular design, with key maintenance points designed for ease of use. Centralized lubrication systems and hydraulic opening devices make daily maintenance simpler and safer than with stationary equipment.

3: How do I choose the right primary crushing solution for my mine?

A: The choice depends on several key factors, including: the hardness of the raw material, particle size, desired capacity, final product specifications, and ore body distribution. We recommend providing detailed operating conditions, and our technical engineers will provide you with a free, customized primary crushing solution.

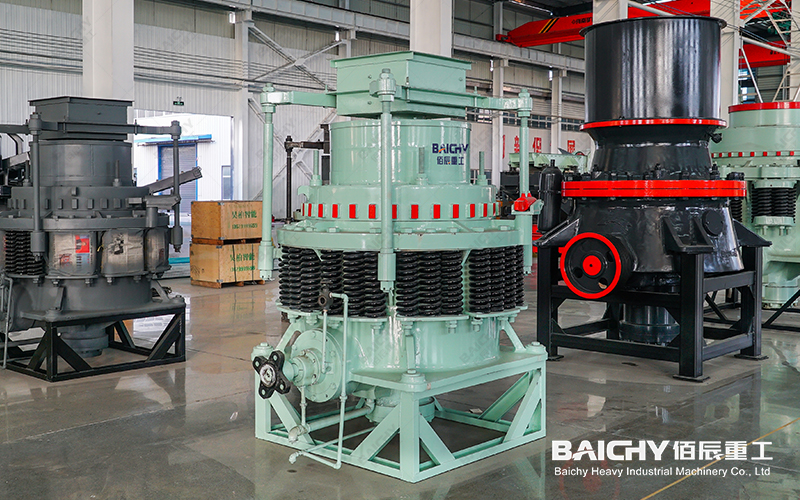

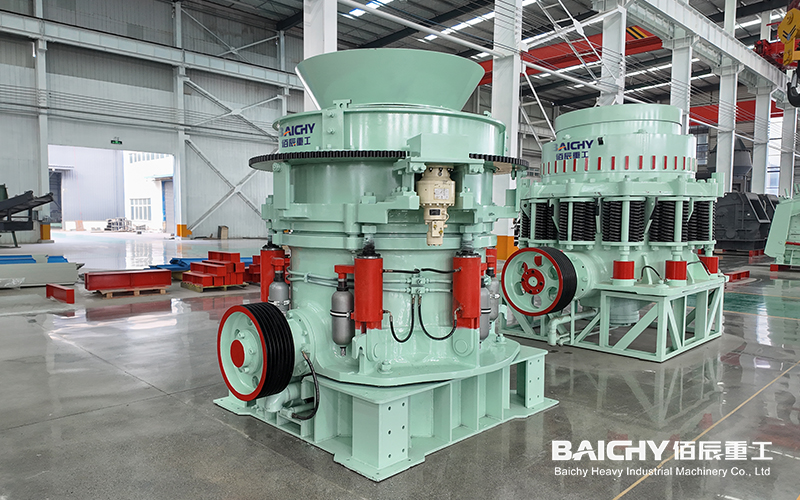

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!