Gypsum Crusher

Gypsum is widely used in building materials, cement retarders, medicine, food additives, etc. However, gypsum raw materials can only be used in industrial production after being crushed by a gypsum crusher. Which crushing equipment can be used to crush gypsum?

In general, a stone crusher is recommended. If the particle size of the gypsum material is large, we usually use primary crushing equipment: jaw crusher and impact crusher.Performance Advantages Of Gypsum Crusher:Bacihy specializes in the production of all kinds of mobile crushers for more than 20 years.Therefore, Baichy’s gypsum crusher machine has many excellent features:

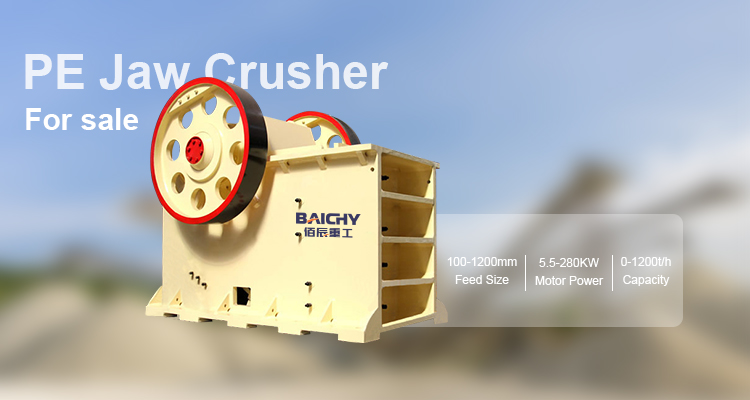

Jaw Crusher

Jaw Crusher

This is a type of crusher that is widely used in the primary and secondary crushing processes. In general, the size of the feed material, which is between 800 and 1500 mm, is reduced to between 150 and 300 mm.

It is usually preferred for the crushing of large blocks of hard and abrasive materials.

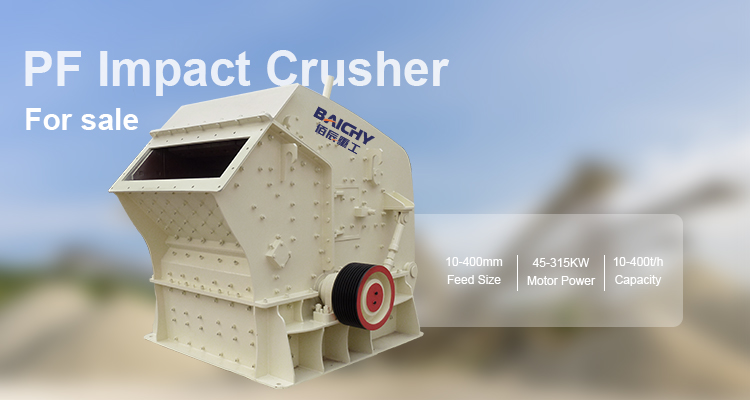

Impact Crusher

Impact Crusher

An impact crusher is generally used for aggregate production, mining operations, and concrete recycling and crushing; it is known for its high crushing ratio and uniform output particle size; An impact crusher is a machine that uses blow instead of pressure to reduce the size of material.

The working process of the 100t/h gypsum crushing production line:

In most cases, the gypsum crushing production line is mainly composed of a vibrating feeder, jaw crusher, impact crusher, circular vibrating screen, belt conveyor, and other stone crushing machines.

First: Coarse crushing stage

We usually use a jaw crusher as the primary crusher. This kind of crusher has a large crushing particle size and a large feed particle size. Therefore, after being crushed by the jaw crusher, the large-sized gypsum can be turned into smaller materials.

Second: finely crushed stage

Baichy recommends that you use an impact crusher at this stage. The working principle is that the rotor driven by the motor rotates at high speed. When the raw material enters the blow bar area, it will be crushed by the blow bar on the rotor. Then the material is thrown into the counterattack device to be crushed again and then crushed again with a hammer. Reciprocating this process, the material can be crushed repeatedly through three crushing chambers until the material is crushed to the required particle size. Then discharge from the discharge port.

Third: Screening stage

Baichy recommends that you use a vibrating screen to screen the crushed material at this stage. Our screening machines are characterized by high efficiency, compact structure, and unique design. Various screening requirements can be met. Gypsum materials can be screened into different specifications: such as 0-5mm, 5-10mm, 10-20mm, and other specifications.

Now there are more and more gypsum crusher manufacturers in the market. So it's hard to choose a really reliable one. Here, I highly recommend Bacihy Group. As a reliable mining machinery exporter, our equipment has been exported to more than 150 countries in the past 20 years. All our crushers are known for high quality, compact design, good performance, excellent functionality, and other features. Please feel free to contact us!