Professional Cement Crushers for Sale | Direct Sales from a 20-Year Mining Equipment Manufacturer

In mining, building demolition, road construction, and even the cement production cycle itself, cement crushers are core pre-processing equipment. Their performance directly impacts the efficiency, cost, and quality of subsequent production. As a mining crushing equipment manufacturer with 20 years of experience in the industry, we deeply understand the importance of an excellent crusher to the success of our clients' projects. This article will comprehensively analyze the topic of cement crusher sales to help you make an informed decision.

Why is the demand for cement crushers consistently strong?

Cement crusher does not refer to a single machine type, but rather a general term for equipment used to crush medium-to-high hardness materials such as cement clinker, slag, concrete blocks, and construction waste. Three main factors drive this strong demand:

1. Continuous development of infrastructure and real estate: This generates a large amount of concrete construction waste, creating an urgent need for recycling.

2. Cement production process requirements: Efficient crushing of raw materials such as limestone, clay, and iron ore is necessary.

3. Environmental protection and resource utilization policies: Resourceful disposal of construction waste has become a mandatory trend, generating a large demand for crushing production lines.

Therefore, choosing a suitable crusher means grasping the key to improving efficiency and controlling costs.

Equipment Overview: Common Types of Cement Crushers

Based on the crushing principle and output particle size, mainstream cement crushing equipment can be pided into the following categories:

PE Jaw Crusher

• Jaw Crusher: Used for primary coarse crushing. Like the iron jaws of the equipment, it is known for its simple structure, reliable operation, and large processing capacity. It is the first stage in the crushing production line, specifically designed to handle large raw materials.

Hydraulic Cone Crusher

• Cone Crusher: Used for medium and fine crushing. It uses the principle of layered crushing and is suitable for crushing high-hardness materials (such as cement clinker and pebbles). It has the advantages of low energy consumption, low wear, and good product particle shape, making it an ideal choice for obtaining high-quality aggregates.

PF Impact Crusher

• Impact Crusher: Used for medium and fine crushing, especially adept at processing medium-to-low hardness materials and construction waste. It uses impact energy for crushing, producing mostly cubic-shaped products with excellent particle shape. It also has a stone-on-stone self-crushing function, which effectively reduces the consumption of wear parts. • Mobile Crushing Plant: Integrates feeding, crushing, and screening systems onto a mobile chassis, enabling crushing on the go. Particularly suitable for demolition sites, urban construction waste treatment, and small mines requiring frequent relocation, greatly enhancing operational flexibility.

Our Core Advantages: Why Choose Us?

With 20 years of technological accumulation and market experience, we offer not just equipment, but trustworthy solutions.

• Deep Technical Expertise: 20 years of focus on the mining crushing field, a continuously innovating R&D team, and four generations of equipment upgrades ensure proven stability and efficiency.

• Comprehensive Product Range: From fixed production lines to mobile crushing plants, from coarse crushing to fine crushing, we offer a complete product matrix, allowing us to customize the most economical configuration for you.

• Excellent Wear Resistance and Durability: Core crushing components (such as jaw plates, impact plates, and cone liners) use new composite high-manganese steel or alloy materials, treated with special processes, extending service life by 30%-50%, significantly reducing your operating costs.

• Intelligent and Environmentally Friendly Design: The new generation of equipment is equipped with an intelligent control system for real-time monitoring of operating status; it also focuses on sealing and noise reduction to meet increasingly stringent environmental requirements.

• Full Lifecycle Service: From site survey, solution design, installation and commissioning to operation training and spare parts supply, we provide technical support throughout the entire equipment lifecycle, ensuring your peace of mind.

Successful Case Studies

Case Study 1: Raw Material Crushing Line Upgrade for a Cement Group

◦ Challenge: The original production line equipment was aging, had high power consumption, and the output could not meet the expansion needs.

◦ Solution: We configured a combination of a new high-capacity jaw crusher (coarse crushing) and a multi-cylinder hydraulic cone crusher (medium and fine crushing) for them.

◦ Results: The production line's hourly output increased by 40%, the product particle size was uniform, and the overall power consumption decreased by approximately 18%, resulting in high customer satisfaction.

Case Study 2: Construction Waste Resource Utilization Project

◦ Challenge: The processed material had a complex composition (including rebar, wood, etc.), limited site space, and required rapid relocation. ◦ Solution: We recommend a combination of a track-mounted mobile jaw crusher and a mobile impact crusher, equipped with a magnetic separator and a light material separator.

◦ Results: This achieves on-site crushing, sorting, and resource utilization of construction waste, producing recycled aggregates of different specifications, and significantly shortening the project's return on investment period.

Impact crushing production line

Related Equipment Recommendations

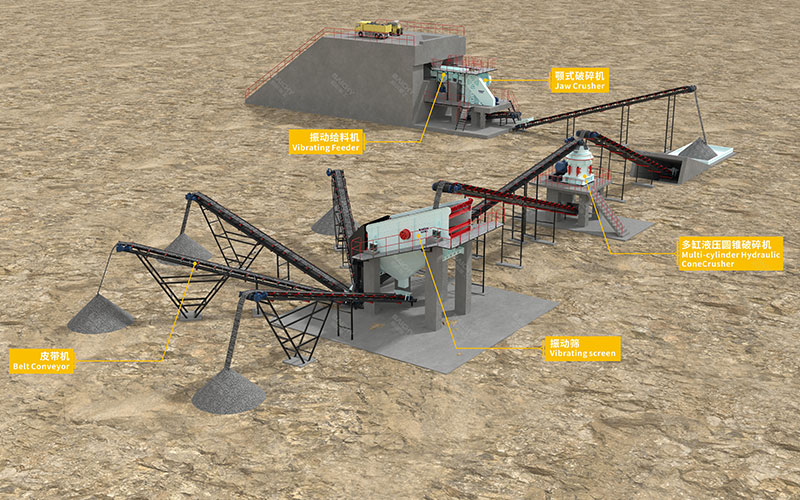

When selecting a cement crusher, the following equipment is often needed to form an efficient production line:

1. Vibrating Feeder: Provides uniform and continuous feeding to the crusher, which is essential for ensuring full load and efficient operation of the crushing chamber.

2. Circular Vibrating Screen: Classifies the crushed material, screening out qualified products and returning unqualified materials to the crusher for further crushing, forming a closed-loop cycle to ensure the final product particle size.

3. Belt Conveyor: The artery connecting each process stage; its stable operation ensures the smooth operation of the entire production line.

4. Dust Removal System: Dust collectors are installed at crushing, screening, and discharge points, which are essential facilities for green mining and environmentally friendly production.

Frequently Asked Questions (FAQ)

Q1: For processing cement blocks and construction waste, should I choose an impact crusher or a cone crusher?

A: If the material has high hardness (such as pure cement blocks, concrete beams), and strict requirements for flaky and elongated particles, a cone crusher is recommended due to its better wear resistance and particle shape control. If the material composition is more complex (containing bricks, mortar, etc.), and the finished product particle shape (for brick making, etc.) and cost-effectiveness are more important, an impact crusher is a better choice.

Q2: What are the advantages of a mobile crushing plant compared to a fixed production line?

A: The biggest advantage of a mobile plant is its flexibility. It eliminates the need for foundation pouring and steel frame installation, allowing for quick deployment and rapid commissioning, making it particularly suitable for projects with short construction periods and dispersed sites. Fixed lines are suitable for long-term, large-scale, and centralized production, with higher single-machine processing capacity and potentially lower long-term operating costs.

Q3: Can you provide on-site testing?

A: Absolutely. We have a complete testing base with various models of machines in stock. You are welcome to bring your materials to our factory for on-site inspection and testing to witness the crushing effect firsthand – this is the most direct way to verify equipment performance.

Q4: Is the supply of critical wear parts for the equipment guaranteed?

A: We have a robust spare parts center with a constant inventory of wear parts worth millions of dollars (such as jaw plates, impact plates, side liners, etc.), and we guarantee shipment within 72 hours to ensure your production will not be interrupted for extended periods due to waiting for parts.

If you are looking for a reliable cement crusher for your project, or have any questions about the configuration options, please feel to contact us. With 20 years of professional experience, we are ready to provide you with comprehensive services from equipment selection to after-sales support.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.