According to the mineral properties and discharge requirements, the filling rate of general ball is 32-45%, and the density of steel ball is about 4.5t/m ³。 The density of high alumina ceramic ball is about 3.7t/m ³。 The wet ball mill mainly depends on grinding rather than impact in the grinding process, so the steel ball filling rate is slightly lower, and the steel ball filling rate of dry ball mill is slightly higher.

How to judge the appropriate ball loading?

First method is to check the fineness of the final product, if the final product meets the requirement, and also no big fluctuate, it proves the mill is running normally,and shows the feeding material is suitable, the gradation of the ball is also suitable.

If the ball mill has high output but coarse fineness, the adjustment method: reduce the grinding media size of the coarse grinding bin and reduce the ball filling rate of the coarse grinding bin.

If the output of the ball mill is low but the fineness is coarse, the adjustment method: increase the loading ball of the coarse grinding bin, increase the ball size of the coarse grinding bin, and reduce the grinding media size of the fine grinding bin.If the output of the ball mill is low, the fineness is fine. When the feeding amount is increased, the return occurs. Adjustment method: increase the grinding body of coarse grinding bin and increase the size,check whether the partition board is blocked and whether the filling rate of fine grinding bin is too high.

Second is to listen the sound of the mill, normally should be issued a "buzzing" sound mixed with a slight impact. If the sound becomes dull,issued a "roaring" sound and cannot hear the impact sound, it indicates too much material in the grinding chamber, if seriously, will appear so-called full grinding phenomenon, at that time, must stop feeding material.

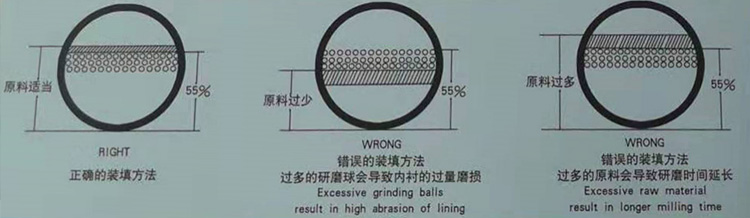

For the correct ball loading, the proportion of balls is roughly higher than the center line of the hollow shaft, and the discharge port of the hollow shaft cannot be stuck, accounting for about 55% of the total volume of the mill. You can use a bamboo rod thrust into the ball mill cylinder from the checking door and make remarks, and then compare to the standard 55% position line.

When the equipment is feeding normally, the voltage is normal and the moisture content of the material is normal, if the current is low, it means that the grinding media is less; if the current is high, it means that the grinding media is loaded too much.For ball mills with two or three chambers, the maximum ball diameter of the second bin is generally one level smaller than the minimum ball diameter of the first bin. The material ball ratio of open circuit ball mill is 4-6 for the first bin and 7-8 for the second bin.

Steel ball proportioning method

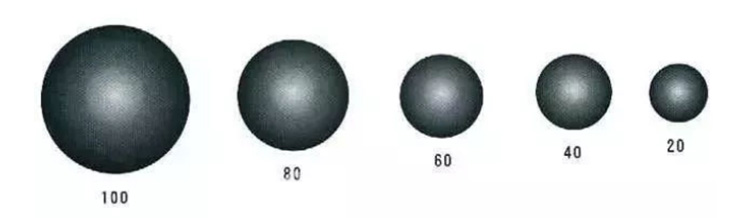

Comparison table of steel ball diameter and feed particle size

|

球径/Ball diameter(mm) |

120 |

100 |

90 |

80 |

70 |

60 |

50 |

40 |

30 |

|

入料粒度/ Feed particle size(mm) |

12-18 |

10-12 |

8-10 |

6-8 |

4-6 |

2-4 |

1-2 |

0.3-1 |

<0.3 |

The maximum ball diameter is determined according to the maximum feed particle size. Then, according to the needs, can adopt four graded balls, or three graded balls, and two graded balls.

Take the material and do separating test, calculate the proportion of feed particle size: (according to the large ball, medium ball and small ball, the middle value can be taken in groups, such as φ 100, 70, 40mm. Or φ 80, 50 and 30mm, and the feeding particle size shall be taken and combined, like the φ 100mm balls used for 8-18mm feeding size, and φ70mm balls used for 2-8mm feeding size, like this method ).

Here supposed 2.4x4.5m ball mill , the total ball loading of the ball mill, assuming Q= 30t

The following table shows the ball diameter φ 100,70,40mm for demonstration

|

入料粒度/ Feed particle size(mm) |

%比例 %Proportion |

球径(mm) Ball diameter |

装球量 t(Qx%) Ball loading |

|

8-18 |

30 |

100 |

9 |

|

2-8 |

45 |

70 |

13.5 |

|

0-2 |

25 |

40 |

7.5 |

Steel ball supplement method

After determining the pellet size and proportion. To calculate the daily series ball consumption index (kg /t)

Determine the loss of grinding ball according to the quantity of grinding materials per day. Properly adjust the ball loading proportion, and only install the large ball diameter quantity of coarse grinding bin and fine grinding bin.

In general, the consumption of grinding balls is related to the material and the fineness of the discharge. The iron beneficiation is 0.8-1kg/t ore, and the gold beneficiation is about 0.8-1.2Kg/t ore. The high chromium ball is used for grinding at about 0.3-0.5Kg/t ore, and the general steel ball gradation is 120mm 100mm 80mm 40mm.

In short, according to the working conditions, material conditions and required powder fineness, each manufacturer can master the adjustment method according to its own situation, find out the best value of the factory in production, improve the output and reduce the ball consumption at the same time.