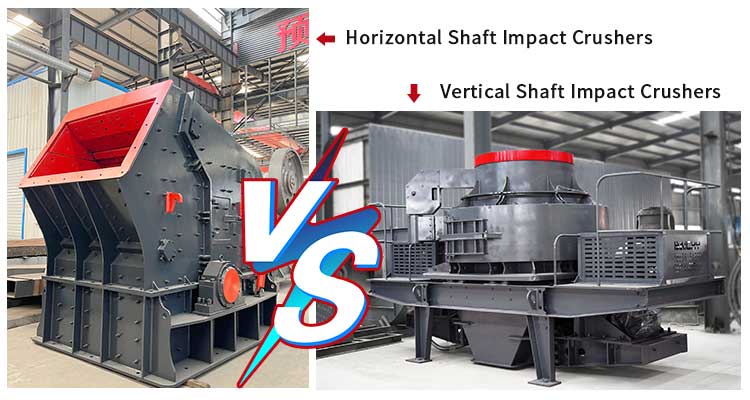

How To Choose Between Horizontal And Vertical Impact Crushers?

Impact crushers, as the backbone of modern mining crushing operations, have a structure that directly impacts production efficiency, finished product shape, and operating costs. Horizontal shaft impact crushers (typically HSI series) and vertical shaft impact crushers (typically VSI sand making machines) are the two main types on the market. For mining investors, this is not simply a matter of choosing between horizontal and vertical, but a critical decision concerning the entire production line process matching and return on investment. As a manufacturer with 20 years of experience in mining crushing equipment manufacturing, we deeply understand the core differences and application scenarios of both.

Fundamental Differences Between the Two Technologies

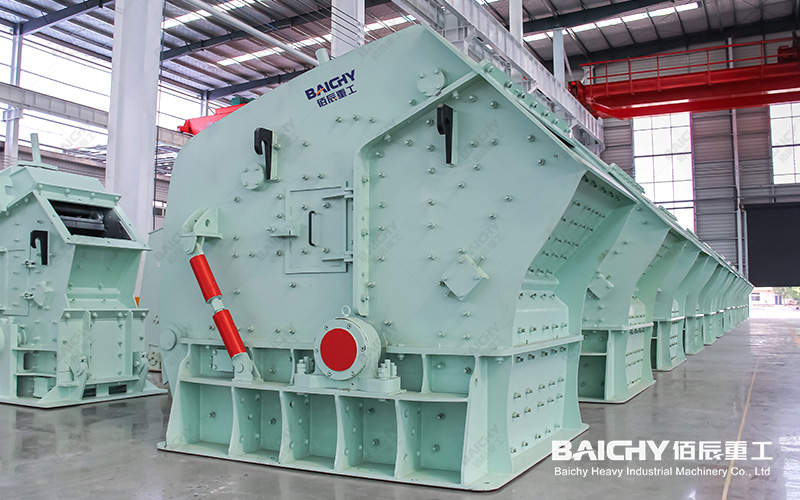

Horizontal shaft impact crushers are characterized by a horizontally placed rotor. Material enters through the feed opening and is struck by the high-speed rotating rotor's blow bars, then projected onto the impact plates for secondary or multiple crushing, finally exiting through the discharge opening at the bottom. The crushing process is primarily rock-on-metal, suitable for medium and fine crushing of medium-soft materials.

Vertical shaft impact crushers have a vertically placed rotor. Material enters through a central feeder into the high-speed rotating rotor, is accelerated and then projected out from the flow channel, impacting and being crushed by the surrounding material lining (rock-on-rock) or wear plates (rock-on-metal). Its characteristic is the flexible conversion between rock-on-rock and rock-on-metal crushing, making it a key piece of equipment for high-performance sand making and particle shaping.

Advantages Comparison: Tailored to Suit, Each with its Strengths

Advantages of Horizontal Impact Crushers

Advantages of Horizontal Impact Crushers

- High throughput: Suitable for processing large, medium-hard materials, with high efficiency in secondary crushing after primary crushing.

- Convenient maintenance: Main wear parts such as blow bars and impact plates can usually be replaced from the side or top of the equipment, resulting in short downtime.

- Cost-effective: The initial investment is relatively low, and for applications primarily focused on crushing with less stringent requirements for particle shape, the overall cost advantage is significant.

Advantages of Vertical Impact Crushers

Advantages of Vertical Impact Crushers

- Excellent particle shape: The finished material is mostly cubic, with low needle and flake content, making it an ideal choice for producing high-grade aggregates and manufactured sand. - Multi-functional: By adjusting the rotation speed and the ratio of central feeding to cascade feeding, it can flexibly switch between sand making and shaping modes.

- High Energy Efficiency: The stone-on-stone principle enables self-lining, reducing wear on wear parts, resulting in controllable operating costs in the long run.

Practical Application Case

We configured a basalt aggregate production line with a capacity of 500 tons per hour for a large building materials group in East China. In this line, our large horizontal impact crusher was used in the secondary crushing stage, efficiently crushing 300mm material from the primary jaw crusher to below 50mm; multiple vertical impact crushers were used in the fine crushing and sand making stage, producing high-quality manufactured sand with continuous gradation and excellent particle shape, as well as high-quality crushed stone of 5-10mm and 10-20mm. The products fully meet national high-standard building material requirements, achieving significant economic benefits. This case fully demonstrates the synergistic concept of horizontal crushers for high output, vertical crushers for quality assurance.

How to Choose? Our Professional Recommendations

1. Scenarios where Vertical Impact Crushers (VSI) are preferred:

- The core business is the production of high-quality manufactured sand.

- There are strict requirements for the particle shape (cubic) of the finished aggregate.

- The material is of medium to high hardness (such as granite, river pebbles, basalt) and the purpose is fine crushing, ultra-fine crushing, and shaping.

2. Scenarios where Horizontal Impact Crushers (HSI) are preferred:

- Medium-scale aggregate production lines processing medium to low hardness materials such as limestone.

- The production line mainly focuses on the secondary crushing stage, pursuing high throughput and lower cost per ton.

- The budget is relatively limited, and ease of maintenance is an important consideration.

As an experienced manufacturer, we can not only provide inpidual machines but also offer complete crushing and screening solutions including horizontal impact crushers and vertical impact crushers, scientifically configuring the line based on your materials, site, budget, and product goals.

Frequently Asked Questions (FAQ)

Q: Can vertical impact crushers handle large materials?

A: It is generally not recommended. Vertical shaft impact crushers are more suitable for fine crushing and sand making of medium-sized materials (generally with a feed size less than 50mm). Large materials should be initially and intermediately crushed by jaw crushers, cone crushers, or horizontal shaft impact crushers.

Q: Which type has higher wear part costs?

A: This depends on the abrasiveness of the material. For highly abrasive materials, the wear of the blow bars and impact plates in horizontal shaft impact crushers may be faster; in vertical shaft impact crushers operating in rock-on-rock mode, wear is transferred to the self-lining layer formed by the material, resulting in a longer lifespan for the core wear parts. However, when replacement is needed, the cost of the rotor, impeller, etc., is also higher. A full life-cycle cost analysis should be conducted based on specific working conditions.

Q: Can you provide trial run services?

A: Absolutely. We have a comprehensive testing facility, and we welcome you to bring representative material samples for crushing tests. Through actual measured data (output, particle shape, energy consumption, and wear), you can make the most informed decision.

Q: What are the core competitive advantages of your equipment?

A: Based on 20 years of technological accumulation, the core advantages of our equipment are:

① Heavy-duty rotor design with large rotational inertia, providing strong crushing force and stable operation;

② Optimized flow channel and crushing chamber design to ensure a balance between high throughput and excellent particle shape;

③ Modular design of wear parts for faster replacement, and the use of our exclusive ultra-high chromium alloy material to extend service life.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.