"What is a Jaw Crusher?"

"What is a Jaw Crusher?" is one of the frequently asked questions by investors new to the stone and mining industry. Jaw crushers are frequently used machines in the stone and mining industries, and they are widely used as crushers for primary and secondary crushing processes. It is often the first choice for breaking large pieces of hard and abrasive materials.

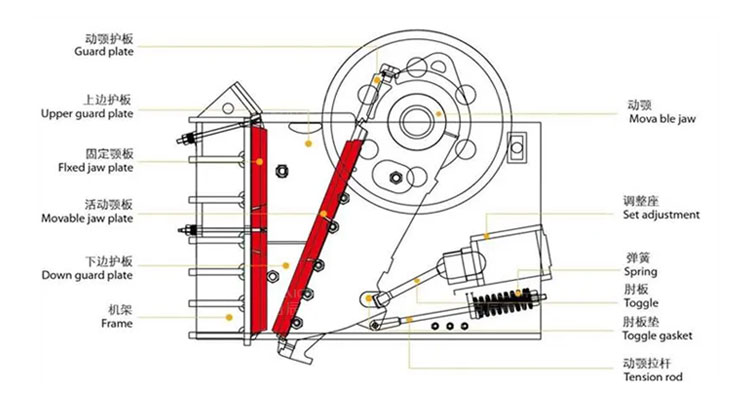

The fixed body, jaw plate part, and adjustment block of the jaw crusher are all made of sheet metal structure, which improves production efficiency. The connecting rod part of the machine is made of cast steel. The jaws of the crusher are made of cast steel such as magnesium or chrome. The lining and chin are logical from the inside out. When one side wears out, you can use the other. Rubber wedges are used for the tension section.

"How does A Jaw Crusher Work?"

How does a jaw crusher work? / Working principle of jaw crusher

All jaw crushers have two jaws: one fixed and the other moving. The working principle of the jaw crusher is based on the reciprocating motion of the movable jaw, which compresses and breaks the rock or ore between itself and the fixed jaw as the material enters the area between the jaws. Get Latest Price

The movable jaw moves back and forth relative to the fixed jaw, and the material fed from the top of the machine is compressed between the two, breaking it into smaller pieces. When the movable jaw is far away from the fixed jaw, the crushed material is discharged from the bottom of the crusher, and the size of the discharged material is determined by the gap between the jaw plates.

Jaw Crusher Production Line Case

In June 2019, a construction company in the Philippines approached our promoters because they were going to carry out a road construction project and wanted to crush granite raw materials (250mm to 500mm) into 1-5mm and 5-10mm sizes10 -20mm, due to the heavy workload, it needs to crush 150t/h of granite.

According to the customer's information, we have customized the granite crushing solution for the customer, including a jaw crusher, cone crusher, sand making machine, and YK vibrating screen.

We choose the PE-600x900 model for coarse crushing, which fully meets the customer's demand for output. We add cone crushers and sand makers to our secondary and tertiary crushing equipment to optimize product granules and ultimately obtain high-quality finished products.

If you want to know more about our equipment, you can contact our technical staff, we will provide you with free design and complete solutions according to your project.