Difference Between Jaw Crusher And Hammer Crusher

In the mining crushing field, jaw crushers and hammer crushers are two of the most commonly used and essential primary crushing equipment. As a mining crushing equipment manufacturer with 20 years of experience, we understand the confusion customers face when selecting equipment.

Why is it necessary to clarify the differences between the two?

Although jaw crushers and hammer crushers both belong to the category of crushers, their design philosophy, applicable scenarios, and ultimate benefits are quite different. Incorrect selection will not only lead to low production efficiency and failure to meet product particle size requirements, but will also significantly increase operating costs and maintenance burdens. Understanding their core differences is the cornerstone of successful mining project operation.

Equipment Overview and Working Principles

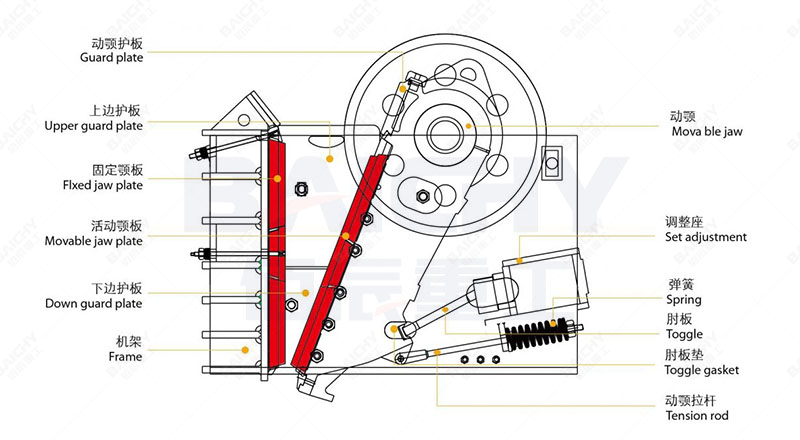

PE Jaw Crusher Structure Diagram

Jaw Crusher

- Working Principle: It crushes materials through the periodic squeezing and bending action between a moving jaw and a fixed jaw. Its working method is similar to the chewing action of an animal's jaws, hence the name jaw crusher.

- Core Structure: Composed of main components such as a fixed jaw plate, movable jaw plate, eccentric shaft, and thrust plate. The structure is robust and highly reliable.

- Feeding and Discharging: Usually handles large blocks of material, with a large feed size and adjustable discharge size, but the product particle size tends to be more flaky.

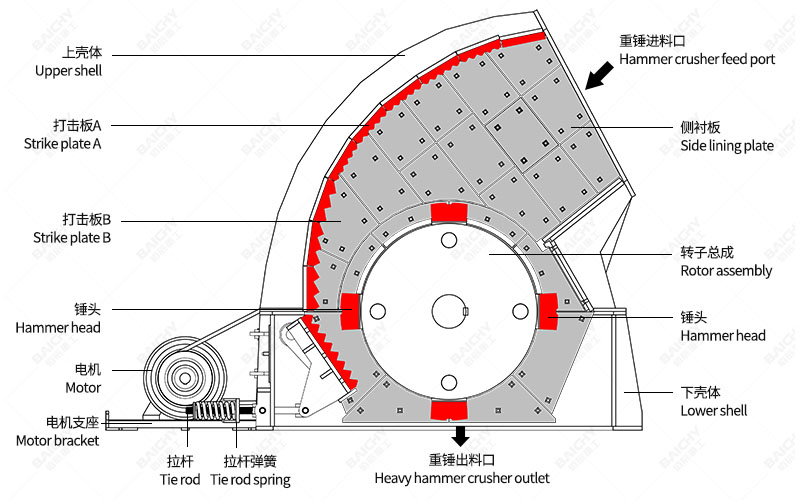

Heavy-duty hammer crusher structural diagram

Hammer Crusher

- Working Principle: It crushes materials by impact, striking, shearing, and grinding using high-speed rotating hammers. It belongs to impact crushing.

- Core Structure: Mainly composed of a rotor, hammers, impact plates, and screen plates. The hammers are the key wear parts.

- Feeding and Discharging: Can achieve one-time feeding to the required particle size, with a large crushing ratio and good product particle shape, mostly cubic.

Core Advantages Comparison

| Feature | Jaw Crusher | Hammer Crusher |

| Crushing Method | Compression, bending | Impact, striking |

| Wear Resistance | Very high, especially suitable for high-hardness materials (such as granite, basalt) | Average, hammer heads wear quickly, not suitable for highly abrasive materials |

| Product Particle Shape | Average, higher content of needle-shaped and flaky particles | Excellent, good particle shape, reasonable gradation |

| Materials with High Water/Mud Content | Strong processing capacity, less prone to clogging | Prone to clogging, sensitive to material moisture |

| Maintenance Costs | Lower, long jaw plate lifespan | Higher, requires frequent replacement of hammer heads and screen plates |

| Energy Consumption | Relatively low | Relatively high |

| Applicable Stage | Primary crushing (coarse crushing) preferred | Often used for secondary and fine crushing, can also be used for primary crushing (with hardness requirements) |

Practical Application Case Selection Reference

- Case 1: Large Granite Quarry

- Challenge: High material hardness (Mohs hardness level 7 or above), requiring high processing capacity and stable operation.

- Our Solution: We recommend a jaw crusher as the primary crusher. Its powerful compression crushing ability and excellent wear resistance ensure continuous and stable operation under harsh working conditions, resulting in the lowest cost per ton.

- Case 2: Limestone Cement Production Line

- Challenge: Medium-hard material, requiring good product particle shape for the production of high-quality aggregates.

- Our Solution: We recommend a hammer crusher for single-stage crushing. Its one-time forming feature simplifies the process, and the resulting particle shape is excellent, meeting the high standards of commercial concrete plants for aggregates.

Equipment Selection and Related Recommendations

There is no absolute best choice, only the most suitable one. Based on 20 years of experience, we recommend:

1. First, consider the material: For high-hardness, highly abrasive, and large-sized materials, choose a jaw crusher.

2. Consider budget and operation: For long-term stability and low maintenance, choose a jaw crusher. Initial investment may be slightly lower, but consider the subsequent costs of replacing wear parts and downtime; a hammer crusher requires careful cost analysis.

3. Consider the process flow: In a complete crushing and screening production line, a jaw crusher often serves as the primary crusher, followed by a cone crusher, hammer crusher, or impact crusher for secondary and tertiary crushing.

We recommend: For most hard rock mines, the combination of jaw crusher (primary crushing) + cone crusher (secondary and tertiary crushing) is the most durable and cost-effective solution.

Frequently Asked Questions (FAQ)

Q1: Can a hammer crusher replace a jaw crusher as the primary crusher?

A: In situations where the material hardness is not high (such as limestone, bluestone) and there are specific requirements for particle shape, a single-stage hammer crusher can simplify the process and achieve one-step forming. However, for hard rock, using a hammer crusher as the primary crusher will lead to extremely rapid wear of the hammer heads, resulting in poor economic efficiency.

Q2: Which equipment offers more flexible output adjustment?

A: Jaw crushers control the maximum particle size of the product by adjusting the discharge opening size, offering a wide and reliable adjustment range. Hammer crushers mainly adjust the product particle size by changing the gap of the bottom screen plate, which is relatively less convenient.

Q3: What are the biggest differences in maintenance between the two?

A: Jaw crusher maintenance focuses on regularly checking jaw plate wear and the lubrication system, with longer maintenance cycles. Hammer crusher maintenance focuses on frequently checking and replacing the high-speed rotating hammer heads, side liners, and screen plates, resulting in greater maintenance workload and spare parts consumption.

Q4: As an established manufacturer, how do you guarantee equipment durability?

A: Based on our 20 years of experience, we use customized materials and optimized designs for key components (such as the jaw plates and frame of the jaw crusher; the rotor and hammer head material of the hammer crusher), and provide comprehensive operational training and maintenance plans to maximize equipment lifespan.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.