High-Capacity Heavy-Duty Hammer Crusher | Ultra-High Output

High-Capacity Heavy-Duty Hammer Crusher was created to address this core pain point. It's not simply a larger version of a standard hammer crusher, but rather a systematic innovation through structural design, materials, power, and intelligent systems, achieving a leap in single-unit processing capacity to meet the demands of large-scale, intensive production in modern industry.

What is a high-capacity heavy-duty hammer crusher?

The high-capacity heavy-duty hammer crusher is a cutting-edge crushing equipment based on the principles of traditional hammer crushers, but with comprehensive enhanced design. Its core features are reflected in its heavy and large characteristics:

- Heavy-duty rotor: Made of high-strength alloy steel through integral forging or composite casting, it has a large weight and high rotational inertia, resulting in incredible crushing force. It can easily handle medium-hard materials with compressive strength below 200MPa, such as limestone, bluestone, and coal gangue.

- Large crushing chamber: Optimized chamber design achieves a longer material retention and crushing path and a higher throughput rate, laying the physical foundation for high capacity.

- High-power drive: Matched with high-power dual motors or heavy-duty motors, ensuring the rotor maintains a stable speed under heavy load, providing continuous and powerful crushing power.

- Heavy-duty hammer heads and grate plates: Using new wear-resistant alloy materials (such as high-chromium composite, tungsten-titanium alloy), and through structural optimization, the service life is significantly extended, reducing the frequency of downtime for replacement.

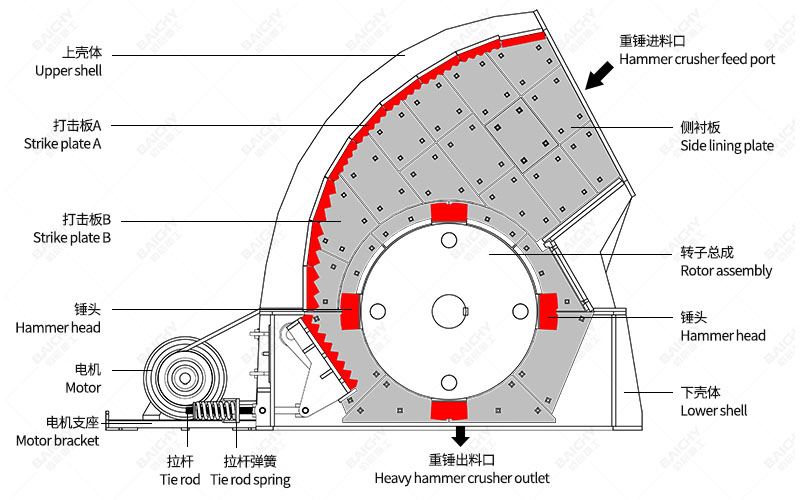

Heavy-duty hammer crusher structural diagram

Why choose our high-capacity heavy-duty hammer crusher?

With twenty years of technological accumulation and practical experience from hundreds of projects, our high-capacity heavy-duty hammer crusher offers the following unparalleled advantages:

1. Capacity leap: Single-unit hourly output can reach 3000-5000 tons, or even higher, perfectly suited for large-scale production scenarios such as large-scale sand and gravel aggregate production lines and cement mines, significantly reducing the number of equipment units and footprint.

2. Excellent energy efficiency: Optimized structural design and transmission system reduce energy consumption per unit of product by approximately 15%-25%, saving customers significant operating costs while achieving high capacity.

3. Excellent discharge particle shape and low fines content: The unique grate plate structure and hammer head trajectory control ensure uniform particle size, low needle-shaped particle content, and high-quality finished product, directly increasing market price.

4. Extremely high reliability: Key components are strength-optimized using finite element analysis (FEA), bearings are selected from internationally renowned brands, and the equipment is equipped with an automatic thin oil lubrication system and hydraulic opening device, resulting in stable operation and significantly increased mean time between failures (MTBF).

5. Convenient maintenance: The machine casing adopts a hydraulic opening design, providing ample space for replacing wear parts such as hammer heads and grate plates, greatly shortening maintenance time and improving equipment utilization.

Heavy-Hammer-Crusher-with-High-Capacity

Practical Case Study: Witnessing the Birth of High-Efficiency Productivity

Project Background: A large cement group in East China, with an annual output of 10 million tons of aggregate production line, uses medium-hardness limestone as raw material. The requirement was for the core crushing equipment of the production line to have a single-machine hourly output of no less than 2000 tons and stable operation.

Solution: We customized a PCZ2125 heavy-duty hammer crusher as the core primary crushing equipment. This equipment has a rotor diameter of 2 meters, a working width of 2.5 meters, and is equipped with two 800kW motors, with each hammer head weighing over 200 kg.

Operating Results:

- The actual average hourly output is stable at 2200-2400 tons, fully meeting and exceeding the design capacity.

- The proportion of finished product with a particle size <25mm exceeds 90%, with excellent particle shape, directly used for high-quality manufactured sand production.

- Since commissioning, the equipment has been running continuously and stably for over 18 months, without any major failures except for normal planned replacement of wear parts.

- Customer feedback indicates that compared to the original plan of using two medium-sized jaw crushers + impact crushers, investment was reduced by approximately 15%, and power consumption was reduced by approximately 20%, resulting in significant overall benefits.

Related Equipment Recommendation: Building an Efficient Crushing System

High-capacity heavy-duty hammer crushers are often used as the core primary or secondary crushing equipment in production lines. To maximize its efficiency, we recommend the following equipment configuration for an optimal system:

- Front End: Extra-large capacity heavy-duty plate feeder to ensure uniform, continuous, and controllable feeding.

- Back End: Multi-layer high-efficiency circular vibrating screen for fine classification of crushed materials.

- Parallel/Shaping: If further improvement of aggregate shape is required, a high-efficiency vertical shaft impact crusher (sand making machine) can be connected in parallel or at the back end for shaping and sand production.

- Control System: Intelligent central control system for interlocking start/stop, load adjustment, and fault warning of all equipment.

Frequently Asked Questions (FAQ)

Q1: Is the heavy-duty hammer crusher suitable for crushing high-hardness materials such as granite and basalt?

A1: Not very suitable. Heavy-duty hammer crushers are primarily designed for materials with compressive strength below 200MPa (medium hardness and below). For high-hardness materials, we recommend jaw crushers and cone crushers as the first choice. Their layered crushing principle is better suited to handle highly abrasive challenges. Although the initial investment may be higher, the wear parts have a longer lifespan, resulting in better overall cost-effectiveness.

Q2: With such a large production capacity, are there any special requirements for foundation construction and installation?

A2: Yes. High-capacity heavy-duty hammer crushers have significant self-weight and dynamic loads, requiring a reinforced concrete foundation that has been rigorously calculated and designed. We will provide detailed foundation construction drawings and installation instructions before equipment delivery, and recommend that a professional team perform the installation and commissioning to ensure a solid foundation for long-term stable operation of the equipment.

Q3: What is the lifespan of wear parts such as hammer heads? Is the replacement cost high?

A3: The lifespan varies greatly depending on the hardness and abrasiveness of the material. For ordinary limestone, our high-chromium composite hammer heads typically have a lifespan of 5000-10000 hours. We offer a variety of hammer head materials to choose from, and have optimized the structure to reduce the weight of each replacement. Although each replacement is a cost, considering the ultra-high production capacity and low downtime, the wear part cost per ton of crushed material is usually very competitive.

Q4: Does the equipment support automated control and remote monitoring?

A4: Absolutely. Our equipment features ample sensor interfaces for easy integration with PLC/DCS control systems. We can provide solutions ranging from single-machine intelligent control (monitoring vibration, temperature, load, etc.) to complete intelligent mining management systems, supporting remote operation and maintenance and data visualization, helping customers achieve intelligent production with unmanned operation and minimal human inspection.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.