1. Project Confirmation

According to previous communication, your needs are as follows:

Project planning: 250 tons of stone production line per hour

Raw ore: river pebbles, raw sand content 20%, raw ore specification: ≤720mm (≤200 content accounts for 50%)

Finished product requirements: 0-5, 5-10, 10-20mm

| No. | Product | Model | Motor Power(kw) |

|---|---|---|---|

| 1 | Vibrating feeder | ZSW1360 | 22 |

| 2 | Jaw Crusher | SKJ8711 | 132 |

| 3 | CS Cone Crusher | CS250M | 250 |

| 4 | CS Cone Crusher | CS160F | 160 |

| 5 | Impact Crusher | VSI5X1150 | 250x2 |

| 6 | Vibrating Screen | 2YK2470 | 30 |

| 7 | Vibrating Screen | 4YK3070 | 55 |

| 8 | Screw Sand | XL1590 | 22 |

| 9 | Belt conveyor | B1200x23m | 22 |

| Belt conveyor | B1000x21m | 15 | |

| Belt conveyor | B1000x22m | 15 | |

| Belt conveyor | B1000x22m | 15 | |

| Belt conveyor | B1200x12m | 11 | |

| Belt conveyor | B1200x12m | 11 | |

| Belt conveyor | B1200x22m | 22 | |

| Belt conveyor | B800x21m | 15 | |

| Belt conveyor | B1200x18m | 15 | |

| Belt conveyor | B1200x29m | 22 | |

| Belt conveyor | B650x15m | 7.5X4 | |

| 10 | Electric control | --- | --- |

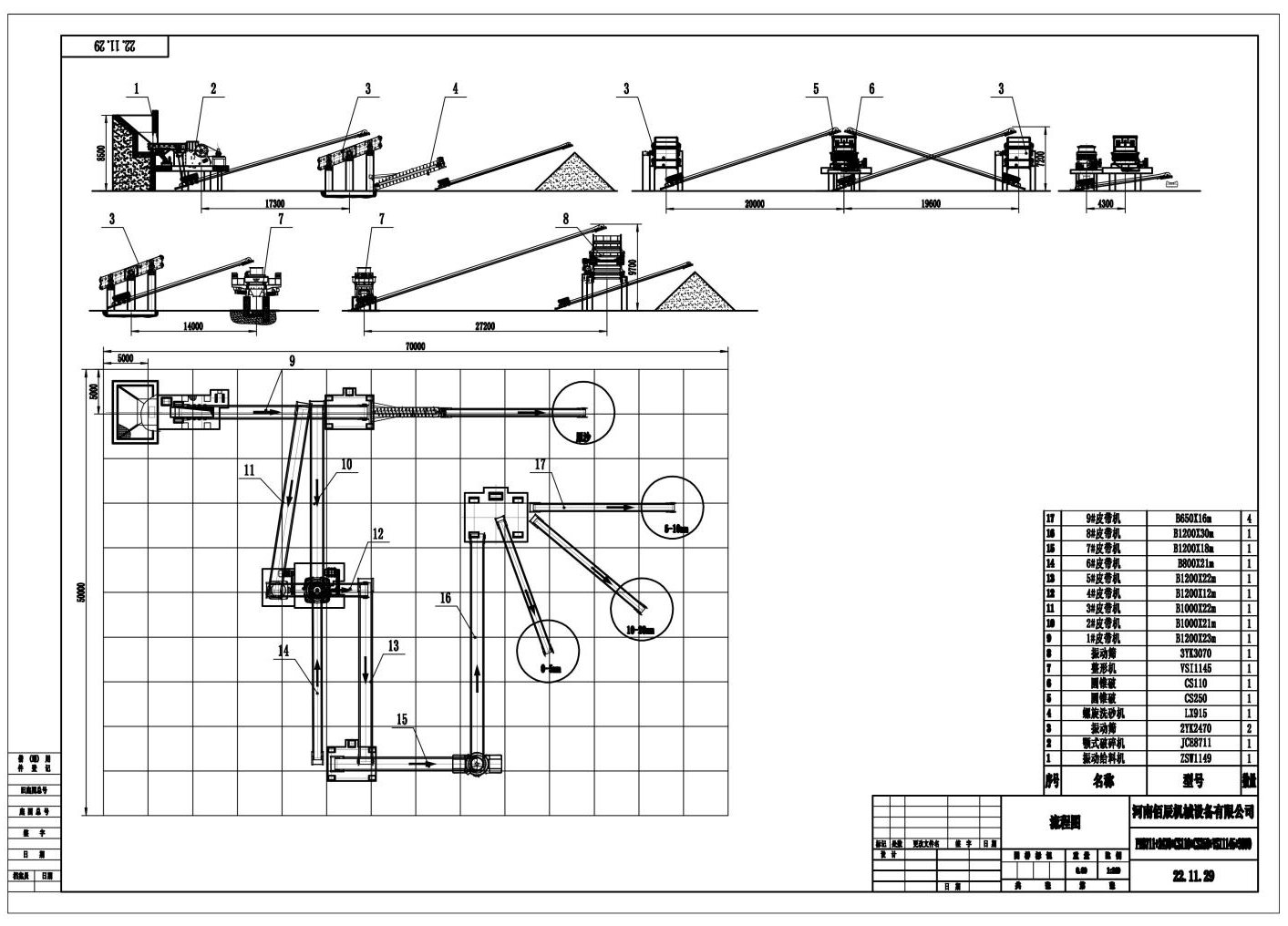

2.2 Process description

1. The feeder adopts a bar-type feeder. According to the proportion of small raw materials, the materials ≤ 80mm are first processed through the grate, and the materials larger than 80mm enter the jaw crusher for crushing. The two materials share a belt conveyor and enter the first stage of screening;

2. The primary screening screens the material into 0-5mm 5-50mm (the size of this material can be adjusted according to the proportion of the raw material to adjust the required range)> 50mm three kinds of material, 0-5mm material enters the spiral sand washing machine for water washing, removes the soil and other impurities in the raw sand, 5-50mm material enters the fine cone for crushing (this fine cone is used to mainly process the finished material contained in the raw material because the finished material in the raw material is mostly round and oval, this kind of material can not be used as sand and gravel aggregates, It must be crushed to make it close to the polyhedron), and the material larger than 50mm enters the crushing cone for crushing. The type selection of the cone is that the size of the medium crushing cone is large, and the size of the fine crushing cone is small because the proportion of the material particle size in the raw material is different. If the proportion of the small material in the raw material is too small and the selection of the fine crushing cone is too large, it will cause a waste of production capacity.

3. The materials coming out of the two crushers enter the secondary screening through the belt conveyor. The 0-25mm material enters the shaping machine for shaping to meet the shaping requirements of the material. The material > 25mm returns to the two cone crushers for secondary crushing. A flap is set in the feeding hopper to control the amount of material entering the two crushers, so as to avoid overloading the capacity of one of the crushers;

4. After the material enters the shaping machine, it enters the three-stage screening through the belt conveyor and screens out the required finished material specifications, such as 0-5 5-10 10-20.