China Crusher Manufacturers

In the global wave of mining and infrastructure construction, Chinese crusher manufacturers have evolved from a geographical label into a synonym for reliability, cost-effectiveness, and innovation. Behind this transformation lies decades of technological accumulation, supply chain integration, and keen market insight from the Chinese manufacturing industry. As a participant and witness to this process, this Chinese crusher manufacturer with 20 years of experience has not only provided equipment but also delivered efficient and reliable systemic solutions, successfully serving numerous projects from Asia Pacific to Africa, and from Europe to the Americas, earning the trust of global customers.

Stone Crushing Plant PDF,Download ↓↓↓

Overview: Twenty Years of Focus, Building the Core Strength of Mining Crushing

We are a Chinese crusher manufacturer specializing in the research, development, manufacturing, and service of mining crushing equipment. For twenty years, we have consistently focused on a full range of products, including jaw crushers, cone crushers, impact crushers, and mobile crushing plants, covering various fields such as sand and aggregate production, metal ore crushing, and construction waste recycling. Our mission is to reduce operating costs, improve production efficiency, and create long-term value for our customers through continuous technological innovation and a rigorous quality control system.

Our Core Advantages

1. Profound Technological Accumulation and Innovation

Twenty years of industry experience have given us a deep understanding of various ore characteristics and working conditions. We have established a comprehensive R&D system and possess multiple patented technologies in areas such as cavity optimization, wear-resistant materials, and intelligent control, ensuring the efficiency and durability of our equipment.

2. Full Supply Chain Manufacturing and Quality Control

As a seasoned Chinese crusher manufacturer, we possess full-process production capabilities from casting and machining to final assembly. A strict ISO quality management system is implemented throughout the process, with 100% inspection of core components such as the main shaft, frame, and hammer plates, guaranteeing equipment reliability from the source.

3. Highly Customized Solutions

We understand the importance of a one-mine, one-solution approach. Our engineering team can provide customers with a full range of personalized solutions, from on-site surveys and process design to equipment selection and installation guidance, ensuring optimal production line configuration.

4. Global Service Network

We have established service centers and spare parts warehouses in several key markets worldwide, staffed with professional service engineers. We are committed to rapid response, providing 24/7 online technical support, on-site maintenance, and original spare parts supply, eliminating customerconcerns.

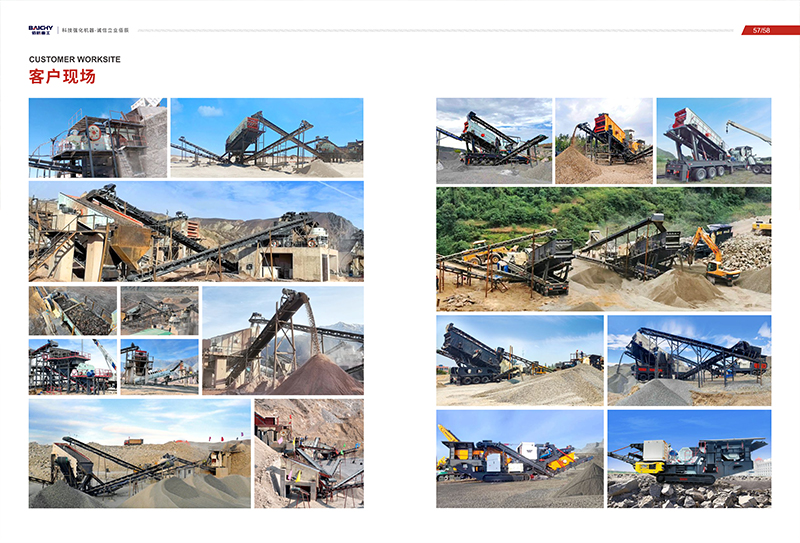

Baichy global customer site

Success Stories

• Case Study 1: Southeast Asia Granite Crushing Project

Customer requirement: 500 tons per hour of high-quality aggregate. We configured a four-stage crushing and screening process for them, consisting of a jaw crusher, a single-cylinder cone crusher, a multi-cylinder cone crusher, and a shaping sand making machine. After three years of operation, the production line has a low equipment failure rate, excellent product particle shape, and fully meets the needs of the local high-end construction market. The return on investment far exceeded the customer's expectations.

• Case Study 2: Central Asia Iron Ore Crushing Project

Facing high-hardness iron ore, we recommended a combination of a heavy-duty jaw crusher with an extra-large feed opening and a cone crusher with hydraulic overload protection. Special wear-resistant materials increased the lifespan of wear parts by 35%, significantly reducing the customer's crushing cost per ton of ore and helping them improve their competitiveness in the international iron ore market.

Product Series Recommendations

• C Series Jaw Crusher: Large feed opening, strong crushing force, a reliable choice for primary crushing.

• HPC Series Hydraulic Cone Crusher: Suitable for medium and fine crushing, high degree of automation, and uniform product particle size.

• CI Series Impact Crusher: Combines stone-on-stone and stone-on-iron crushing, specifically designed for producing high-quality manufactured sand.

• Wheeled/Tracked Mobile Crushing Station: Modular design, flexible relocation, especially suitable for urban construction waste treatment and dispersed mining operations.

Frequently Asked Questions (FAQ)

Q1: As a Chinese crusher manufacturer, where does the cost-effectiveness of your equipment lie compared to international brands?

A1: Our core advantage lies in providing comparable or even superior technical performance and reliability, while offering better procurement costs (thanks to China's complete supply chain), shorter delivery times, and more competitive spare parts prices. In addition, our customized services can better meet your specific budget and needs.

Q2: How do you guarantee after-sales service and spare parts supply after purchasing the equipment?

A2: We provide a global warranty. During the warranty period, we offer free remote technical support and on-site service under certain conditions. We have spare parts warehouses in major markets to ensure that commonly used parts are shipped within 72 hours. We also provide clear parts diagrams and codes to support customers in sourcing some common parts locally.

Q3: Can you provide a trial run or arrange a visit to an existing production line?

A3: Absolutely. We welcome customers to visit our factory to inspect the equipment manufacturing process and conduct trial runs. We can also arrange for you to visit a customer site that processes similar materials (with their consent), allowing you to gain a more intuitive understanding of the equipment's actual performance.