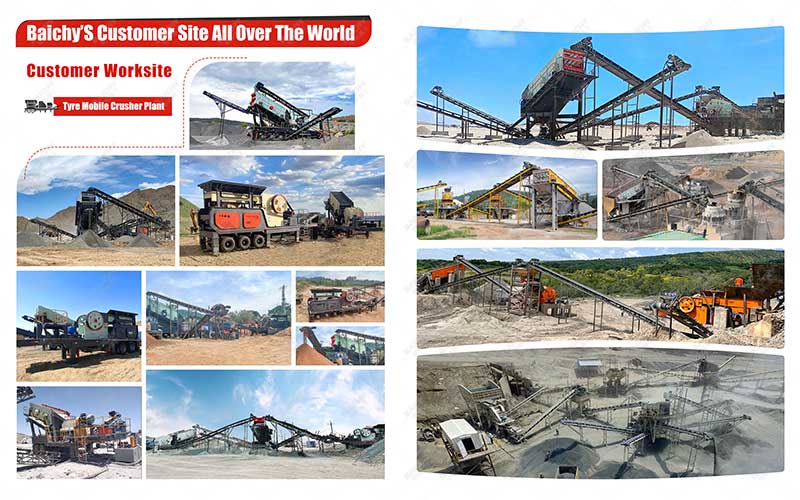

Baichy Heavy Industry Global Customer Site

In mining, aggregate production, and even infrastructure construction, crushers are undeniably the heart of the industry. Their performance directly determines production efficiency, finished product quality, and operating costs. Faced with a dazzling array of crusher models on the market jaw crushers, cone crushers, impact crushers, and more a core question arises: Which crusher is best for you?

As a manufacturer of mining crushing equipment with 20 years of R&D and manufacturing experience, we understand that the answer to this question is not simply recommending a particular best machine. The real answer lies in matching a perfect match between your production needs, material characteristics, and equipment performance. Blindly choosing popular or expensive equipment often leads to a series of problems such as insufficient capacity, rapid wear of vulnerable parts, and poor finished product particle shape.

This article, drawing on our 20 years of industry insights, will provide you with a clear and practical selection logic to help you make the wisest decision.

Step 1: Understand Your Raw Materials

When selecting equipment, raw materials come first. The vastly different physical properties of different materials are the primary basis for selection.

• Hardness and Abrasiveness: For high-hardness, highly abrasive materials such as granite and basalt, jaw crushers using the layered crushing principle should be prioritized for coarse crushing, while cone crushers should be used for medium and fine crushing. These have robust structures and more durable wear parts. Conversely, for medium- to low-hardness materials such as limestone and limestone, impact crushers are a more cost-effective choice, as their impact crushing principle produces better particle shape.

• Feed Size and Moisture Content: What is the size of your raw material? If it contains a lot of mud and moisture, is pre-screening or washing necessary? Sticky materials may clog the crushing chamber of certain models, requiring special design.

Step Two: Define Your Output Goals

What are your requirements for the final product? This directly determines the design of the crushing process flow and equipment configuration.

• Capacity Requirements: What is your expected hourly or daily output? This is crucial in determining the size of the equipment. Avoid using undersized equipment for large tasks, and also avoid using oversized equipment for small tasks, which would lead to wasted investment.

• Finished Product Specifications and Particle Shape: How many specifications of finished product do you need? Are there high requirements for the particle shape (cubic, needle-like and flaky content) of the stone? For example, aggregates used for high-grade highway surface courses or commercial concrete have stringent particle shape requirements, and vertical shaft impact crushers (sand making machines) are ideal for producing excellent particle shapes. If only a single specification of crushed stone needs to be produced, the process can be simplified.

Matching Core Equipment Characteristics

Step 3: Matching Core Equipment Characteristics

After clarifying the first two steps, we can precisely match the requirements with the characteristics of the equipment:

• Jaw Crusher – King of Coarse Crushing: Characterized by a large feed opening, it can handle huge raw stones. Its simple structure and reliable operation make it the first barrier in a crushing production line. If your raw material is large, it is an irreplaceable starting point.

• Cone Crusher – Expert in Medium and Fine Crushing: Excels at handling hard rock, offering high efficiency and relatively low wear costs, making it particularly suitable for high-volume secondary crushing stages. The crushed product has a uniform particle shape, but the equipment investment and maintenance technology requirements are higher.

• Versatile – Impact Crusher: Utilizes rotor impact crushing to produce high-quality finished product with easily adjustable discharge particle size. Suitable for medium to low hardness materials, it combines crushing and shaping effects, typically with lower investment costs.

• Shaping and Sand Making Powerhouse – Impact Crusher: Designed specifically for obtaining high-quality manufactured sand and high-standard cubic crushed stone, it significantly reduces needle-like and flaky content through a stone-on-stone or stone-on-iron principle.

Step Four: Beyond the Equipment Itself – Choosing the Manufacturer's Value

A manufacturer with 20 years of experience offers much more than just a machine. We recommend considering the following when making your decision:

• Process Design: Excellent manufacturers will provide customized production line layouts and process flow diagrams based on your site conditions.

• Core Component Quality and Durability: The wear-resistant materials used in vulnerable parts such as jaw plates, mantle walls, and hammers directly impact your long-term operating costs.

• Technical Support and After-Sales Service: Does the manufacturer provide timely installation guidance, operation training, maintenance support, and spare parts supply? This determines the stable operation of the equipment throughout its lifecycle.

Which crusher is best for you? The answer lies in your specific production conditions and long-term development plans. There is no one-size-fits-all solution, only the optimal configuration tailored to your needs.

As your trusted partner, with 20 years of technical expertise and extensive project experience, we are willing to be your professional advisor. Please feel free to contact our technical team, providing your raw material information, capacity requirements, and budget. We will provide you with a customized, cost-effective equipment selection and solution.