About Of Talc

Talc, also known as painting stone, liquid stone, of stone, cold stone, finite, and co-stone, is a common silicate mineral with a Mohs hardness of 1. It is a known soft mineral and can replace chalk. There are white marks, and nails can leave scratches on the talc. Talc is generally blocky, leafy, fibrous, or radial in shape, white or off-white in color, and may be colored by other impurities.

| Fineness | Application Scenario | recommended equipment |

| Within 200 mesh | Used as feed, such as fish feed, etc., and also used as other additives; | MTW Grinding Mill |

| 200-325 mesh | Drilling, paper making, etc. | MTW Grinding Mill |

| More than 325 mesh | Chemical additives, paper | HGM grinding mill |

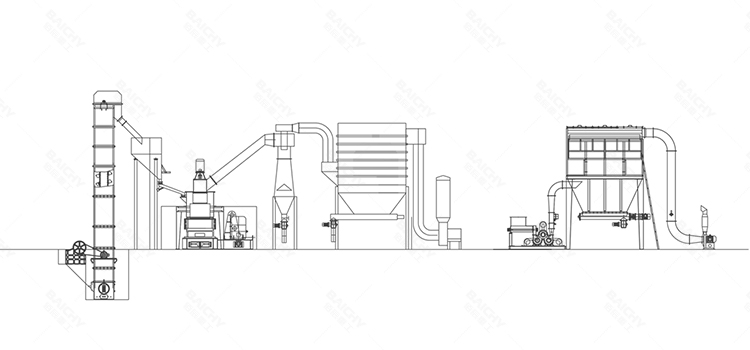

Talc Processing Technology

1. Crushing stage: large pieces of material are crushed by the crusher to the feed fineness that can enter the mill (15mm-50mm)

2. Milling stage: The small pieces of materials that meet the grinding conditions are uniformly and quantitatively entered into the grinding chamber of the mill through the conveying and feeding system, and are ground into powder in the grinding chamber.

3. Classification stage: The ground materials are classified through the powder classifier with the system airflow, and the unqualified powder is classified by the classifier and returned to the main mill for re-grinding.

4. Powder collection stage: the fine powder enters the powder collection system with the airflow through the pipeline, the air and powder are separated, and the finished powder is sent to the finished product silo by the conveying device, and then uniformly packed with a powder tanker or an automatic packing machine.

Recommended machines for Talc grinding mill

According to different uses and different discharge fineness, the choice of Talc mill will also be different.

In the fields of mineral processing and powder manufacturing, talc powder, as an important industrial raw material, is widely used in industries such as plastics, coatings, ceramics, and cosmetics. The quality and fineness of talc powder directly affect the performance of the final product. Therefore, a high-efficiency talc powder grinding mill (also known as a talc powder milling machine) is particularly crucial. It not only determines the fineness and uniformity of the powder but also directly impacts production efficiency and cost control.

Why choose a professional talc powder grinding mill? Talc powder grinding mills are specifically designed for medium-to-low hardness minerals. Through advanced grinding principles, they can achieve fineness adjustment within the range of 80-2500 mesh, meeting the fineness requirements of different industries. Simultaneously, the equipment uses wear-resistant materials and an intelligent control system, significantly reducing energy consumption and maintenance costs while ensuring powder purity. Whether coarse crushing or ultrafine grinding, modern talc powder grinding mills can achieve stable and continuous production, helping companies enhance their product competitiveness.

Key Advantages and Highlights:

High-precision grading, pollution-free grinding

Automated operation, energy saving and consumption reduction

Adaptable to various production capacity needs, flexible configuration

If you are looking for a reliable talc grinding solution, choosing the right grinding equipment will be an important step in improving quality and efficiency.