Bentonite, hailed as "the universal clay," is widely used in various industrial fields such as casting, drilling mud, metallurgical pelletizing, coatings, and pesticides due to its unique water absorption, swelling, adsorption, and cation exchange properties. However, unprocessed bentonite ore must undergo multiple processes, including crushing, drying, and grinding, to be transformed into high-value-added products that meet the fineness requirements of different industries. In this process, the grinding stage is crucial, directly determining the particle size distribution and chemical and physical properties of the final product.

Why is bentonite grinding so special?

Bentonite is a layered clay mineral. The purpose of grinding it is not only to reduce particle size, but more importantly, to effectively exfoliate its layered structure through mechanical force, increasing the specific surface area and maximizing its activity. Therefore, grinding equipment has special requirements:

• Flexible grinding: It needs to possess both shear force and friction to avoid over-grinding that could damage the crystal structure.

• Temperature control: Bentonite is sensitive to temperature; excessively high grinding temperatures can affect its physicochemical properties.

• Pollution-free: The equipment material must avoid introducing impurities such as iron to ensure the whiteness and purity of the product.

How to Choose the Ideal Bentonite Mineral Grinding Mill?

There are many types of grinding mills on the market, but not all are suitable for bentonite. Here are some efficient and commonly used options:

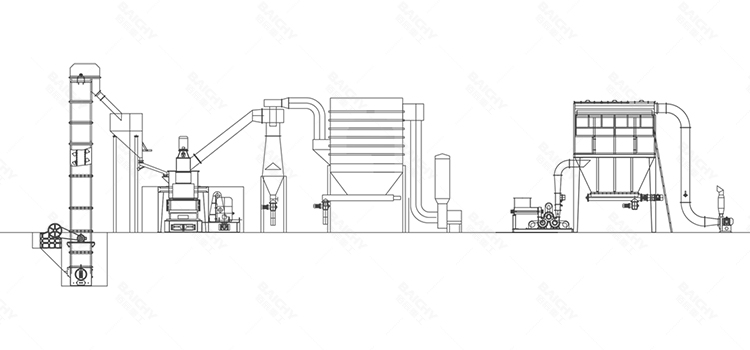

1. Raymond Mill (Suspension Roller Grinding Mill)

◦ Features: Mature technology, stable operation, and the mainstream equipment for processing coarse bentonite powder (80-400 mesh). It adopts the suspension roller pressing and air classification principle, resulting in relatively low energy consumption.

◦ Applications: Suitable for fields where extremely high fineness requirements are not necessary, such as bentonite for drilling mud and foundry bentonite.

2. Vertical Grinding Mill

◦ Features: Integrates drying, grinding, and classification, resulting in high production efficiency. It adopts the bed grinding principle, resulting in low energy consumption and a wide range of adjustable product fineness (80-1000 mesh).

◦ Applications: Suitable for large-scale production, especially for hydrated bentonite requiring simultaneous drying and grinding.

3. Airflow Mill

◦ Features: Uses supersonic airflow to pulverize materials through self-collision; no moving parts, low temperature rise, high product purity, and fineness down to microns or even submicron levels (600-2500 mesh).

◦ Applications: Ideal for the intensive processing of high-value-added bentonite products (such as high-end coatings, cosmetics, and pharmaceutical carriers).

Choose us to empower your bentonite business

We focus on providing advanced mineral processing solutions. Our engineers will recommend the most suitable bentonite mill based on your ore characteristics, target fineness, production capacity needs, and budget, and provide a full-process service from equipment selection, installation, commissioning to technical training to help you create competitive bentonite products.