1. Why is the Simmons cone crusher suitable for crushing granite?

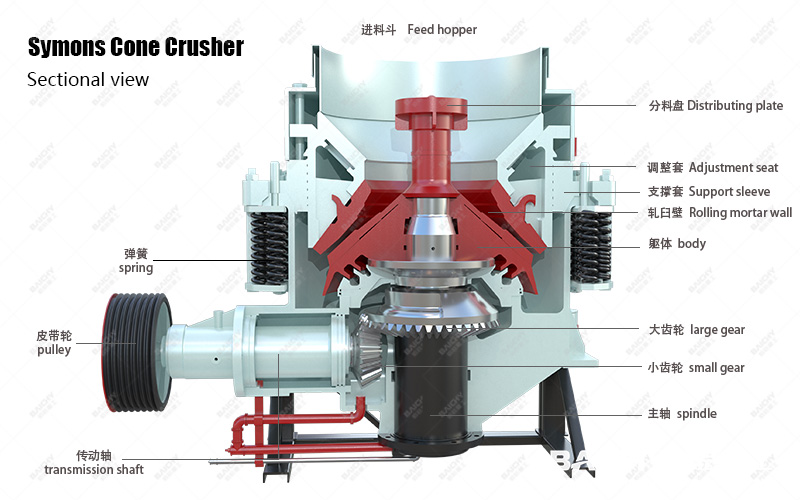

• Working Principle Matching Material Characteristics: The Simmons cone crusher utilizes a laminated crushing principle. The moving cones continuously press the material, causing it to collide and compress within the crushing chamber, crushing it. This method is ideal for hard, wear-resistant, and compressively strong materials like granite, efficiently crushing it into finely shaped cubic particles.

• Powerful Crushing Force: The structural design provides tremendous crushing force, sufficient to withstand granite's high compressive strength (typically 100-300 MPa).

• Stable Performance and Product Size: The equipment operates smoothly, and by adjusting the discharge opening, the final product particle size can be easily controlled to meet the requirements of different specifications (such as 0.5, 12, and 13 granite).

2. Significant Advantages in Crushing Granite

• High Efficiency and Output: The laminated crushing principle enables high production efficiency and high output per unit, making it ideal for large-scale stone production lines.

• Excellent product shape: The produced stone is mostly cubic with low flake content, making it an ideal choice for high-quality concrete aggregate with high market value.

• Relatively manageable operating costs: Although the initial investment in the equipment is high, it achieves high crushing efficiency and relatively reasonable energy consumption. The key lies in the wear resistance of wearing parts (such as the mortar wall and crushing wall).

3. Important Considerations and Challenges

Crushing granite, a highly hard and abrasive material, is also a test for the cone crusher itself. Users should pay special attention to the following points:

• Wear-resistant component material is critical: High-quality wear-resistant components (moving cone and fixed cone lining) made of high-manganese steel, ultra-high manganese steel, or inlaid with wear-resistant alloys must be selected. The wear resistance of the material directly determines the equipment's service life and maintenance costs.

• Strict feed requirements:

◦ Pre-screening: Before entering the cone crusher, it is best to screen the raw material through a vibrating screen to separate the fine material that meets the requirements, avoid over-crushing, and improve efficiency.

◦ Uniform feeding: Feeding must be uniform, continuous, and fill the feed pan ("packed feeding") to achieve effective layered crushing, protect the equipment, and achieve optimal particle shape.

◦ Avoid excessive iron content: If granite contains uncrushable materials such as iron lumps, it can severely damage the cone crusher. An iron remover and metal detector must be installed at the front end.

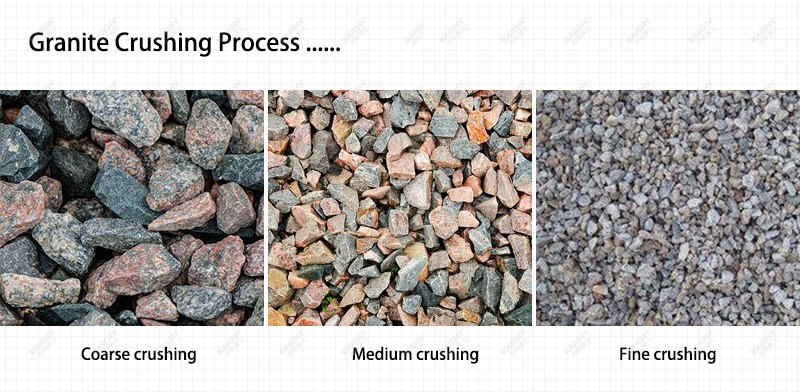

• Selecting the appropriate cavity type: Symons cone crushers offer different cavity designs (such as standard, medium, and short-head). The short-head type is more suitable for producing fine material, while the medium and standard types are more suitable for secondary crushing. Choosing the appropriate model depends on your target product particle size.

The Symons cone crusher is not only capable of crushing granite, but is also one of the ideal equipment for crushing granite. It plays a core role in both secondary and tertiary crushing in modern sand and gravel aggregate production lines.