The core operating principle of a Symons cone crusher is "laminated crushing" (or "intergranular crushing"), which is fundamentally different from the "compression crushing" of a jaw crusher. Its goal is to crush the rocks through mutual compression and friction, rather than simply being crushed by the crusher components. This produces a better-shaped, more cubic product and reduces wear on the machine.

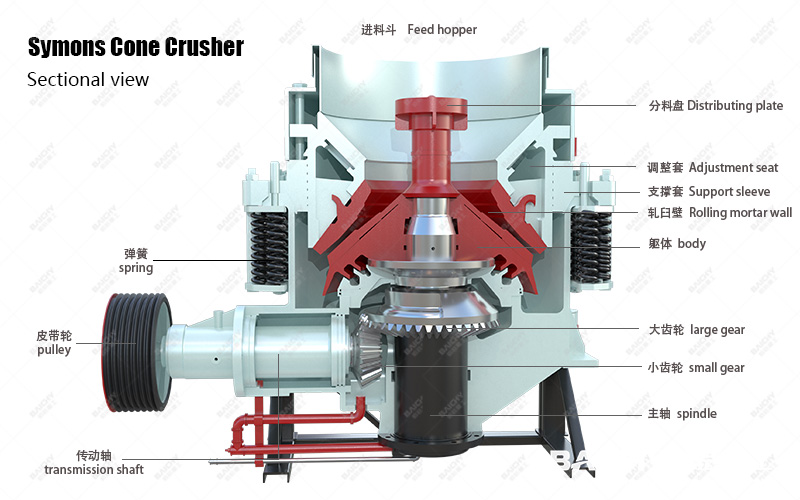

I. Core Components

To understand its principle, it's important to first understand several key components:

1. Fixed Cone (Frame): The crusher's outer casing is stationary.

2. Moving Cone (Crushing Cone): The core crushing element within, driven by the main shaft and large and small bevel gears, undergoes eccentric oscillation.

3. Spring Safety Device: A powerful spring surrounding the crusher. This is a hallmark feature of the Symons cone crusher, providing both the crushing force and a crucial iron-related safety feature.

Download ↓↓↓

II. Detailed Working Process

The working process can be pided into the following steps:

1. Feeding:

Rocks are dropped into the crusher through the feed port at the top. Between the moving cone and the fixed cone lies a space called the crushing chamber. The crushing chamber is pided into a parallel zone above the feed inlet and a crushing zone below.

2. Eccentric Oscillating Motion:

A motor drives a horizontal shaft via a pulley or coupling. The small bevel gear on the horizontal shaft drives the large bevel gear, causing the main shaft (vertical axis) to rotate eccentrically. The moving cone, mounted on the main shaft, moves accordingly. Note that the moving cone does not simply rotate around its own centerline; rather, its centerline moves in a conical motion around the centerline of the machine. This motion causes every point on the moving cone's generatrix to periodically move closer to and further away from the fixed cone.

3. Layered Crushing:

• When the moving cone approaches the fixed cone, the rock between them is squeezed and bent.

• When the moving cone moves away from the fixed cone, rock that has been crushed to a certain size is discharged downward by gravity.

• The key point is that due to the continuous oscillating motion of the moving cone, the rock is not crushed in a single pass within the crushing chamber, but rather experiences multiple cycles of squeezing and friction. Large lumps of stone are crushed into medium-sized pieces at the top, and the medium-sized pieces are further crushed into acceptable product sizes during the downward movement. This "stone grinding stone" method is known as laminated crushing, which produces more cubic-shaped finished products and significantly reduces wear on wear-resistant parts.

4. Discharge and Particle Size Adjustment:

Crushed material is discharged from the discharge port at the bottom of the crusher. Product particle size is primarily controlled by adjusting the size of the discharge port:

• Raising/Lowering the Moving Cone: By adjusting the adjustment sleeve at the top of the crusher, the overall height of the moving cone can be changed, thereby varying the gap between the moving cone and the parallel area at the bottom of the fixed cone (i.e., the discharge port). A smaller gap results in a finer discharge particle size; a larger gap results in a coarser discharge particle size.

5. Iron Overload Protection (the core function of the spring safety device):

This is a very ingenious design feature of the Simmons cone crusher. When unbreakable foreign matter (such as iron) enters the crushing chamber, the crushing force increases dramatically, exceeding the force required for normal stone crushing.

• The immense force forces the movable cone upward, compressing the powerful spring supporting it.

• As the movable cone is lifted, the discharge opening instantly increases, allowing foreign matter (iron blocks) to be discharged smoothly.

• After the foreign matter is discharged, the crushing force returns to normal, and the compressed spring pushes the movable cone back to its original position, allowing the machine to resume normal operation.

This process provides automatic over-iron protection and reset, significantly protecting the machine's core components (such as the main shaft and frame) from damage.

III. Working Principle Dynamic Diagram

IV. Summary: Main Features of the Simmons Cone Crusher

• Advantages:

◦ Laminated Crushing: High output, fine product shape, and low needle-like content.

◦ Spring Safety: Reliable over-iron protection and a high degree of automation.

◦ Stable Operation: Mature technology and high reliability.

◦ Wide Application: Suitable for medium and fine crushing of ores and rocks of various hardnesses.

• Disadvantages (compared to modern hydraulic cone crushers):

◦ Difficulty adjusting: Adjusting the discharge opening requires manual operation while stopping the machine, making it less convenient than a hydraulic cone crusher.

◦ Difficulty clearing the cavity: When a blockage occurs, manual cleaning is required, while a hydraulic cone crusher can quickly clear the cavity by hydraulically raising and lowering the cone.

◦ Low degree of automation: Unlike a hydraulic cone crusher, it lacks the real-time adjustment and automated control capabilities of a hydraulic cone crusher.

We hope this detailed explanation, from the principles to the features, will help you fully understand how a Simmons cone crusher works.