In the mining and aggregate processing industries, Symons 7-foot cone crushers are highly sought after for their durability and stable performance. However, the choice of their core wear component the cone liner (usually referring to the combination of the crushing wall and the mortar wall) directly determines final product particle size and production efficiency. Many users are confused between standard and short-head liners. This article will thoroughly clarify the differences between the two and provide practical selection and maintenance guidelines.

1. Understanding the Symons 7-foot Cone Liner

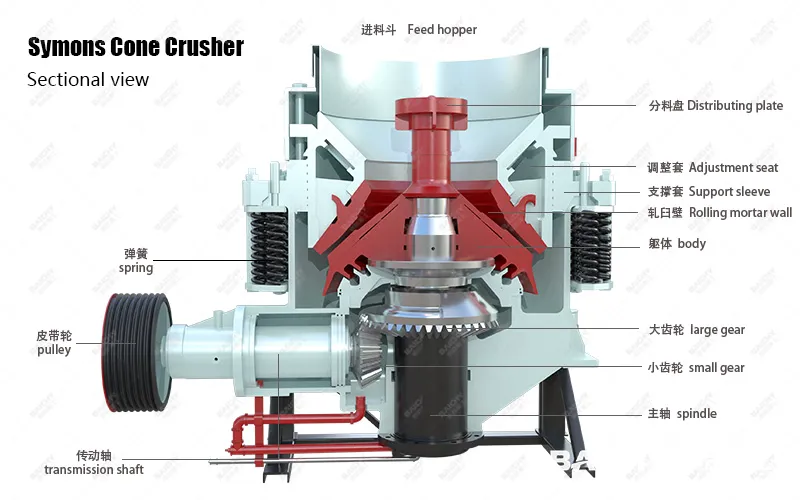

The crushing chamber of a Symons cone crusher consists of two components: the crushing wall (moving liner) mounted on the moving cone and the mortar wall (fixed liner) mounted on the fixed cone. The cavity shape formed by these two components is crucial to crushing performance. The terms standard and short-head primarily refer to the different cavity shapes formed by the combination of these two liners.

Download ↓↓↓

2. Standard vs. Short-head: A Detailed Explanation of the Core Differences

Although both are 7-foot specifications, the design objectives and application scenarios of standard and short-head liners are quite different.

1. Comparison of Crushing Chamber Shapes

◦ Standard Liner: The crushing chamber is coarser and shorter, with a wider feed opening and a shorter parallel zone.

◦ Short-Head Liner: The crushing chamber is thinner and longer, with a narrower feed opening and a longer parallel zone, ensuring multiple crushing of the material.

2. Feed and Discharge Particle Size

◦ Standard Liner: Suitable for medium-sized feeds, primarily used in the secondary crushing stage. Its output product is relatively coarse, but it has a higher processing capacity.

◦ Short-Head Liner: Suitable for finer feeds, primarily used in the tertiary crushing stage. Its long parallel zone enables laminated crushing of the material, producing finer, better-shaped products. However, the throughput per unit is lower than that of the Standard Liner.

3. Main Application Scenarios

◦ Standard Liner: Ideal for secondary crushing in aggregate production, aiming to crush the material to a medium size (e.g., 25-60 mm) while maintaining a certain output.

Short-head liner: Key to achieving the more crushing, less grinding concept, it's commonly used in tertiary crushing or sand making stages to produce high-value machine-made sand or ultra-fine aggregate (e.g., 0-5mm, 5-10mm).

Summary table:

| Features | Standard liner | Short-head liner |

| Main applications | Secondary crushing | Fine crushing, sand making |

| Feed opening | Large | Small |

| Parallel zone | Short | Long |

| Product particle size | Coarse | Fine |

| Processing capacity | High | Relatively low |

| Product particle shape | Good | Excellent |

III. How to choose the right liner? Key factors analysis

Incorrect liner selection can lead to low yields, substandard products, and increased liner wear. Please consider the following factors when making your decision:

1. Production process requirements: Identify your crushing stage (secondary or fine) and target product specifications.

2. Feed characteristics: Consider material hardness, moisture content, and maximum feed size. If the feed material is too coarse, a short-head liner will not be able to effectively handle it.

3. Balancing Capacity and Particle Size: If you're pursuing high output and aren't particular about particle size, choose a standard liner. If you're looking for fine particle size and good particle shape, a short-head liner is the preferred choice.

IV. Liner Maintenance and Replacement Recommendations

1. Replace in Pairs: The crushing wall and mortar wall must be replaced in pairs. Replacing only one part will result in mismatched wear and accelerate the wear of the other.

2. Regularly Check Fasteners: Ensure the liner mounting bolts are properly tightened to prevent loosening and equipment damage.

3. Monitor Wear: Establish a regular inspection system. When there are significant changes in output or product particle size, promptly check liner wear.

Selecting the right Symons 7-foot standard or short-head tapered liner is crucial for optimizing your crushing process, reducing costs, and improving product quality. We hope this article helps you make an informed decision. If you have further questions about selecting the right liner for your specific application, please contact our technical experts for a one-on-one, professional solution.