For aggregate producers, hard stones (such as granite, basalt, and river pebbles) are both an "asset" and a "challenge." Their high hardness and abrasiveness pose a severe test to crushing equipment. A scientifically designed and rationally selected production line is key to cost reduction and efficiency improvement. This article will provide an in-depth analysis of the core configuration of an 80-100 ton/hour hard stone crusher production line, helping you easily overcome the challenges of hard stone crushing.

I. Core Challenges and Design Principles of Hard Stone Crushing

The core of hard stone crushing lies in "layered crushing" and "using hard materials to overcome hard materials." The production line design must follow these principles:

• Multi-stage crushing: Employing multi-stage crushing processes such as coarse crushing, medium crushing, and fine crushing to progressively reduce particle size and lower the load and wear on inpidual equipment stages.

• Pre-screening: Screening out materials that already meet specifications before crushing avoids over-crushing and improves efficiency.

• Equipment selection is crucial: The core crushing equipment must be selected based on models designed for highly abrasive materials, focusing on the materials of wear-resistant parts and structural strength.

II. Classic Configuration Scheme for a Hard Stone Crushing Production Line with a Capacity of 80-100 t/h

Below are two recommended, efficient, and mature configuration schemes, which can be selected based on raw material characteristics, investment budget, and finished product requirements.

Scheme 1: Jaw Crusher + Cone Crusher Core Configuration (Most Commonly Used and Most Stable)

• Process: Vibrating Feeder → Jaw Crusher (Coarse Crushing) → Cone Crusher (Medium and Fine Crushing) → Vibrating Screen (Screening) → Finished Aggregate (Unqualified material is returned to the cone crusher to form a closed-loop cycle).

• Core Equipment Analysis:

◦ Coarse Crushing (Jaw Crusher): Responsible for crushing large raw stones (≤750mm) to medium particle size. Its simple structure and reliable operation make it the ideal choice for coarse crushing of hard stone.

◦ Medium and Fine Crushing (Cone Crusher): The "soul" equipment for hard stone crushing. Utilizing the principle of layered crushing, it boasts high crushing efficiency and long wear-resistant part life, making it particularly suitable for processing high-hardness materials.

• Advantages: Stable output, excellent finished product particle shape (polyhedral, high compressive strength), and controllable operating costs. It is the first choice for large-scale, modern sand and gravel aggregate projects.

Option Two: Jaw Crusher + Impact Crusher Configuration (Suitable for medium-hardness or lower rocks, lower investment)

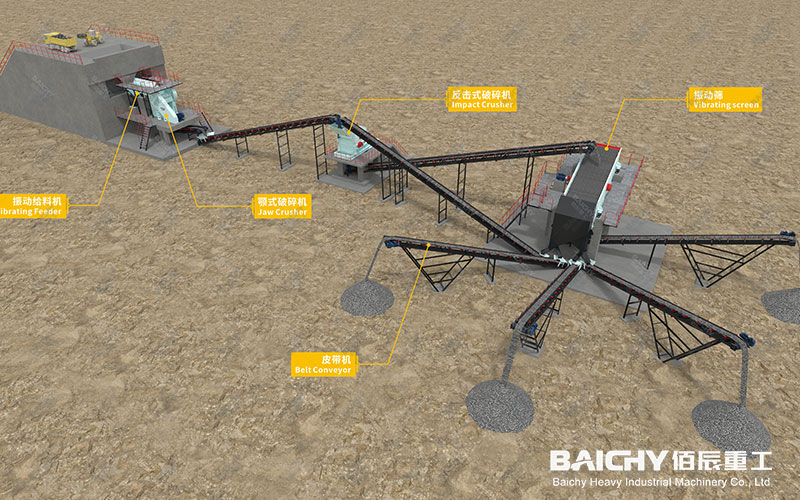

• Process: Vibrating feeder → Jaw crusher (coarse crushing) → Impact crusher (medium and fine crushing) → Vibrating screen (screening) → Finished aggregate.

• Core Equipment Analysis:

◦ Impact Crusher Advantages: Lower investment cost than cone crusher, perfect finished product particle shape (cubic, higher selling price).

• Precautions: The wear of the impact crusher's hammers will be significantly accelerated when processing extremely hard rocks; subsequent maintenance costs must be comprehensively considered. More suitable for conditions with extremely high particle shape requirements and where the raw material hardness is not extreme.

III. Production Line Investment Benefit Analysis

A production line with an hourly output of 80-100 tons, calculated based on 10-12 hours of operation per day, can achieve a daily output of 800-1200 tons. Currently, the market demand for high-quality sand and gravel aggregates is strong, and prices are firm, resulting in a very attractive return on investment. Although the initial equipment investment for a hard stone production line is slightly higher, its stable output and low long-term wear and tear costs ensure maximum profitability throughout the project's lifecycle.

Choosing a suitable hard stone crushing production line is the cornerstone of a successful sand and gravel plant. We recommend that you provide specific stone types, feed sizes, and finished product specifications so that our engineers can tailor the most economical and efficient customized solution for you, along with on-site inspections and equipment commissioning services.