Secondary Impact Crusher Manufacturer | Mobile Crushing Equipment

In the field of mobile crushing, transforming large raw materials into finished aggregates that meet high construction standards is the core value of the entire production process. As a mobile crushing equipment manufacturer with 20 years of experience, we deeply understand that single-stage crushing often fails to balance both output and particle shape. At this point, the choice of the secondary crushing stage is crucial, and the secondary impact crusher is a star device in this field, playing a key role as the finishing expert for aggregates.

Why is secondary impact crushing necessary?

In a stone production line, primary crushing (usually performed by a jaw crusher) is responsible for the coarse crushing of mined raw stone. However, the resulting material often has a high content of flaky particles and uneven particle size, making it unsuitable for direct use as high-grade concrete aggregate or asphalt mixture.

This is where the core mission of the secondary impact crusher comes in: it uses a high-speed rotating rotor to drive the hammer plates to impact the material, and through stone-on-stone or stone-on-metal impact methods, the material undergoes violent collision and grinding in the crushing chamber. This process not only effectively reduces particle size but also significantly improves the cubic particle shape of the aggregate and reduces the content of flaky particles through strong impact crushing. This improves the bulk density, compressive strength, and adhesion to cement, meeting the stringent requirements of the high-end market.

Working Principle and Technical Features

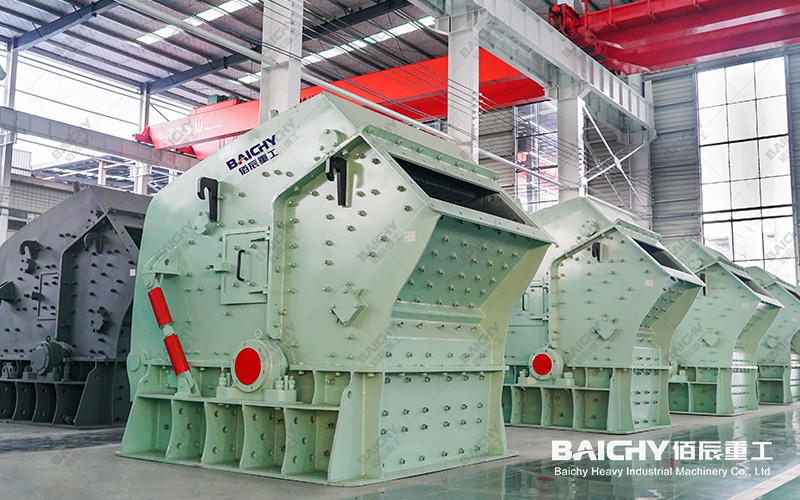

Our Baichy series secondary impact crusher is optimized for secondary and tertiary crushing in mobile crushing plants and fixed production lines. Its core advantages include:

• High-efficiency rotor design: Heavy-duty, high-inertia rotor ensures stable and efficient energy output even when crushing high-hardness materials, resulting in a high crushing ratio.

• Hydraulic assist system: Equipped with a hydraulic opening device, facilitating quick inspection and replacement of core wear parts such as the rotor, hammer plates, and impact plates, greatly reducing downtime.

• Flexible particle size adjustment: By adjusting the rotor speed, feeder, and grinding chamber gap, the output particle size can be flexibly controlled, enabling multi-purpose use and meeting the production needs of various aggregate specifications.

• Robust machine structure: Made of heavy-duty steel plate welding and stress-relieved treatment, ensuring the stability and durability of the equipment under long-term, high-intensity operation. Core Advantages: Why Choose Our Impact Crusher?

Combining our 20 years of technological expertise and market feedback, our secondary impact crusher offers the following irreplaceable advantages:

1. Superior Particle Shape Quality: The finished aggregate produced is cubic in shape, with a reasonable gradation and extremely low needle-like and flaky content, making it an ideal choice for producing commercial concrete and high-grade road surface materials.

2. Higher Production Efficiency: The inherent characteristics of impact crushing result in high processing capacity, making it particularly suitable for crushing abrasive materials of medium hardness and below, such as limestone and gypsum.

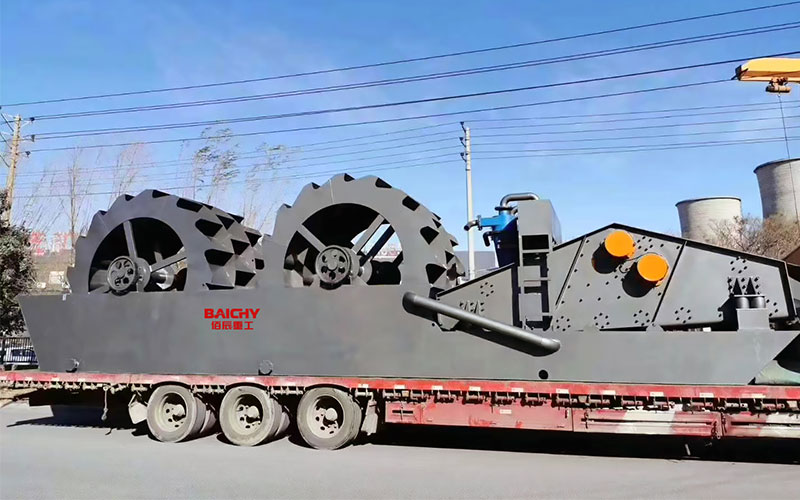

3. Excellent Mobility and Flexibility: As the core machine of a mobile crushing plant, it can be quickly relocated, allowing it to operate directly at raw material sites or construction waste processing sites, significantly reducing material transportation costs.

4. Intelligent and Environmentally Friendly: An advanced PLC control system is available as an option, providing real-time monitoring of operating status. Simultaneously, the enclosed crushing chamber, combined with efficient dust removal interfaces, effectively controls dust emissions, meeting environmental protection requirements.

Secondary impact crushers – Baichy Crushing Plants

Success Stories

At a large green building materials base in East China, a customer used our mobile crushing and screening plant equipped with a secondary impact crusher to process construction waste concrete. This equipment successfully increased the qualified rate of recycled aggregate particle shape by more than 35%, and the high-quality recycled aggregate produced was widely used in the construction of water-stable layers for local municipal roads, achieving a win-win situation in terms of economic and environmental benefits.

Related Equipment Recommendations

• Primary Crushing Partner: PE/PEX series jaw crusher, providing stable primary crushed material for the impact crusher.

• Front-end Feeding Guarantee: ZSW series vibrating feeder, providing uniform and continuous feeding to the crusher.

• Rear-end Screening Key: 3YK/4YK series circular vibrating screen, accurately screening the crushed material into different specifications of finished products.

Frequently Asked Questions (FAQ)

Q: Is the secondary impact crusher suitable for crushing high-hardness rocks such as granite and basalt?

A: It can handle them, but the wear of wear parts (such as blow bars and impact blocks) will be relatively faster. We offer a variety of wear parts materials (such as high-chromium cast iron and ceramic composite materials) to choose from, balancing durability and cost under hard material crushing conditions. For materials with extremely high hardness, a cone crusher can be considered as a secondary crushing solution.

Q: Is there a difference in capacity between the impact crusher on a mobile crushing plant and a stationary one?

A: Under the same model and power, the core crushing performance is the same. Because the mobile plant integrates feeding, conveying, and screening systems, the overall production line design is more compact, and its overall capacity depends on the perfect matching of the entire system. Our advantage lies in providing a one-stop mobile solution.

Q: Is the equipment maintenance complicated?

A: Easy maintenance is a key focus of our design. Through hydraulic opening mechanisms and modular wear parts, daily inspections and replacement of wear parts can be completed within a few hours, with full guidance provided by our technical team.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.