Triple Pass Rotary Drum Dryer VS Single Pass Rotary Dryer

The structure and working principle of the three-pass rotary drum dryer and the single-pass rotary drum dryer

The three-pass rotary drum dryer uses an internal guide structure to dry the material in three stages (high temperature, medium temperature, and low temperature), with high thermal energy utilization, and is suitable for high-moisture or heat-sensitive materials; while the single-pass rotary drum dryer uses a single-drum linear drying method, and the material contacts the hot air only once. It has a simple structure but high energy consumption, and is suitable for rapid processing of low-moisture or non-heat-sensitive materials. The core difference between the two lies in the complexity of the drying process and the heat recovery efficiency.

Three-pass rotary drum dryer structure diagram

1. Three-pass rotary drum dryer

• Structure: The material undergoes three independent drying stages (three stages) in the dryer, and multiple cycles are achieved through internal guide plates or partitions.

• Working principle: The wet material passes through the high-temperature zone, medium-temperature and low-temperature zone in turn, and is dried stage by stage, with high thermal energy utilization.

• Features: long process, controllable residence time, suitable for high moisture or heat-sensitive materials

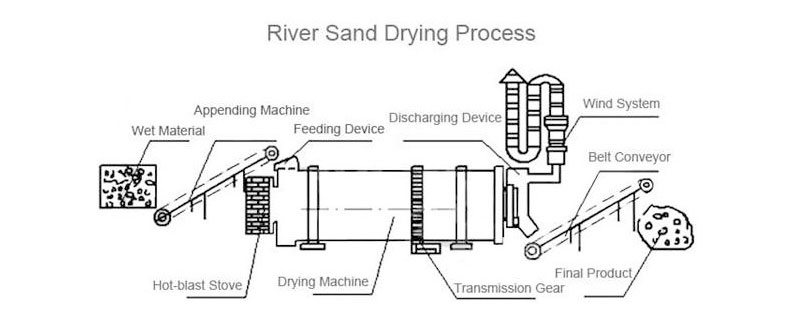

Single-pass-rotary-dryer-structure-diagram

2. Single-pass rotary dryer

• Structure: single cylinder, materials go directly from the feed end to the discharge end, no segmented drying design.

• Working principle: the material contacts the hot air once, and the drying process is short.

• Features: simple structure, suitable for materials with low moisture or no strict requirements on drying time.

Drying efficiency and energy consumption

Three Drum Rotary Dryer

1. Three-pass dryer

• Efficiency: multi-stage drying can deeply dehydrate, and the final moisture content is lower (such as ≤0.5%).

• Energy consumption: segmented utilization of heat energy (such as evaporation of most of the moisture in the high temperature section, fine drying in the low temperature section), low comprehensive energy consumption (saving 20%~30% compared with single-pass).

• Applicable materials: materials with high initial moisture (such as more than 50%), heat sensitivity (such as food, medicine) or that need to be dried at low temperature.

Single Drum Rotary Dryer

2. Single-pass dryer

• Efficiency: Single-pass drying, high moisture content (such as 5%~10%), suitable for occasions with low moisture requirements.

• Energy consumption: Hot air is discharged at one time, waste heat utilization rate is low, and energy consumption is high.

• Applicable materials: low moisture, non-thermosensitive materials (such as ore, sand).

Single-pass-rotary-dryer-site

Equipment cost and maintenance

1. Three-pass dryer

Cost: Complex structure, high initial investment (30%~50% higher than single-pass).

Maintenance: The guide plate needs to be cleaned regularly, which is difficult to maintain, but the service life is long (10~15 years).

2. Single-pass dryer

Cost: Simple structure, low cost, suitable for projects with limited budgets.

Maintenance: Easy maintenance, but the drum is prone to wear (life is about 5~8 years).

Comparison of application scenarios

| Scenario | Three-pass dryer | Single-pass dryer |

| High-moisture materials | Yes (e.g., sludge, biomass) | No (easy to agglomerate and clog) |

| Thermosensitive materials | Yes (quality protection in low temperature section) | No (high temperature may cause denaturation) |

| Continuous large-scale production | Yes (high degree of automation) | Yes (but low production capacity) |

| Projects with limited budget | No | Yes |

Selection suggestions

1. Choose a three-pass dryer:

• The initial moisture content of the material is high, and deep drying is required.

• Strict requirements for product quality (e.g., color, active ingredients).

• Long-term operation requires reducing the overall energy consumption cost.

2. Choose a single-pass dryer:

• Simple drying requirements, high moisture content is allowed.

• Handling non-sticky, non-heat-sensitive materials (e.g., chemical raw materials).

• Limited initial investment or intermittent production.

The three-pass dryer has obvious advantages in energy saving and drying effect, but the cost is relatively high; the single-pass dryer is economical and suitable for simple needs. The actual selection needs to take into account the material characteristics, production capacity requirements, and cost budget. If necessary, you can consult the equipment manufacturer for a customized design.