In industries such as construction, building materials, and precast concrete, controlling the moisture content of river sand is crucial for ensuring product quality. Wet river sand not only affects mixing efficiency but also severely reduces the strength of the finished product. Therefore, a high-efficiency river sand dryer becomes an indispensable core piece of equipment on the production line.

I. What is a River Sand Dryer?

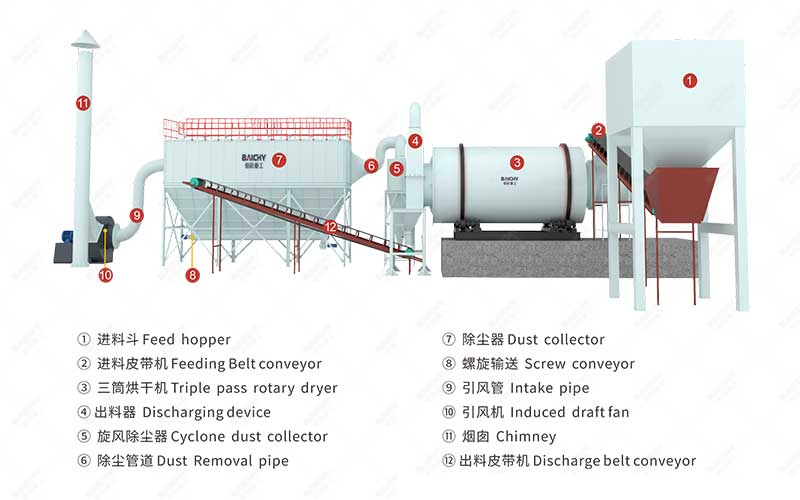

A river sand dryer, also known as a rotary drum dryer, is a drying device specifically designed to process large quantities of granular and powdery materials. It achieves efficient and uniform dehydration and drying by ensuring that hot air comes into full contact with wet river sand inside a rotating drum, rapidly evaporating moisture.

II. How Does a River Sand Dryer Work?

Its working principle is clear and efficient:

1. Feeding: Wet river sand, after preliminary screening, is evenly fed into the drying drum by a conveyor.

2. Drying: The drum rotates slowly under the drive of a transmission device. Special lifting plates inside the drum continuously lift and scatter the river sand, forming a uniform material curtain, allowing it to fully contact the high-temperature flue gas from the hot air furnace for heat exchange.

3. Discharge: After drying, the river sand reaches the standard moisture content (usually reduced to below 1%) and is discharged from the other end of the drum, then transported to a designated location via conveyor equipment. Exhaust gas is purified by dust removal before being discharged.

III. Core Advantages of the River Sand Dryer

• High Efficiency and Energy Saving: Utilizes insulation technology, resulting in high thermal efficiency and significantly reducing fuel consumption and operating costs.

• Large Processing Capacity: Capable of continuous operation, with daily processing capacity ranging from tens to hundreds of tons, meeting the needs of large-scale production.

• Uniform Drying: The unique drum and lifting plate design ensures uniform heating of the river sand, consistent moisture content, and stable quality.

• Stable Operation: Robust structure, low failure rate, adaptable to harsh industrial production environments, ensuring continuous production.

• Environmental Compliance: Can be equipped with various dust removal equipment (such as bag filters) to effectively control dust emissions and meet environmental protection requirements.

IV. Wide Range of Applications

River sand dryers are not only ideal for drying river sand, but are also widely used in:

• Drying of manufactured sand

• Drying of materials such as yellow sand, quartz sand, and mineral powder

• Drying of slag and clay in cement plants

• Dewatering of concentrates and tailings in mineral processing plants

Investing in a high-quality river sand dryer is a key step in improving sand and gravel quality, ensuring production efficiency, and reducing overall costs. Choosing the right drying equipment will create lasting economic benefits for your business.