The main work of the stone crushing plant in the mining industry is to crush and screen the mined raw stones to produce crushed stone products that meet the needs of different projects. The following is a clear process of the stone crushing plant:

1. Crushing in the mining industry:

Pre-crushing: The large stones are sent to the jaw crusher through a vibrating feeder for preliminary crushing to break them into smaller stones.

Fine crushing: The stones after preliminary crushing are sent to the cone crusher or other fine crushing equipment through a conveyor belt for further fine crushing to obtain the required crushed stone particle size.

2. Screening in the mining industry:

The crushed stones are screened by screening equipment and classified according to different particle sizes to meet the needs of different projects. Common stone classifications include sand and gravel (particle size between 2mm and 5mm), aggregate (particle size between 5mm and 20mm) and stone powder (particle size less than 2mm).

3. Application of finished products in the mining industry:

Crushed stone products are widely used in road construction, construction engineering, water conservancy engineering and other fields. For example, sand and gravel can be used to fill and reinforce the roadbed to improve the bearing capacity and stability of the road surface; aggregates can be used to make asphalt mixtures or concrete for paving the structure and foundation of roads or buildings; stone powder can be used for the maintenance and repair of roads.

4. Quality control of finished products:

Throughout the production process, the stone crushing plant needs to strictly control product quality to ensure that the crushed stone produced meets relevant standards and customer needs. This includes regular maintenance and overhaul of equipment to ensure the normal operation of the equipment; quality inspection of raw materials to ensure that the quality of raw materials meets production requirements; sampling inspection of the produced crushed stone products to ensure stable and reliable product quality.

5. Environmental protection:

During the production process, the stone crushing plant needs to pay attention to environmental protection and take effective measures to reduce the emission of pollutants such as noise and dust. For example, sound insulation covers or sound barriers are set around equipment such as crushers and screening machines; dust covers or sprinklers are set in areas such as conveyor belts and stockpiles.

Through the above process, the stone crushing plant can efficiently process raw stones into crushed stone products that meet the needs of different projects, providing strong support for the construction of infrastructure such as buildings and roads.

Key influencing factors

• Stone hardness: determines the type of crusher (e.g., granite requires a cone crusher, limestone can use an impact crusher).

• Capacity requirements: Small plants can process dozens of tons per hour, and large plants can reach thousands of tons.

• Environmental requirements: must meet noise, dust, and wastewater emission standards, and some areas require closed plants.

Frequently Asked Questions (FAQ) about Stone Crushing Plants

1. What is the main equipment in a stone crushing plant?

• Coarse crushing equipment: jaw crusher, gyratory crusher (suitable for large mines).

• Medium crushing equipment: cone crusher (high hardness stone), impact crusher (medium and low hardness).

• Fine crushing equipment: impact crusher (sand making machine), roller crusher.

• Auxiliary equipment: vibrating screen, conveyor belt, dust removal system, feeder, etc.

2. What is the workflow of a stone crushing plant?

• Raw material preparation: mining raw stones → transport to the crushing plant → preliminary screening.

Multi-stage crushing:

• Coarse crushing (100-300mm) → Medium crushing (30-100mm) → Fine crushing (0-30mm).

• Screening and grading: Vibrating screen separates crushed stones by size (such as 0-5mm sand, 5-10mm aggregate).

• Finished product storage: Classified stacking or loading, and transportation.

3. How to choose the right crusher for stones of different hardness?

• High hardness (granite, basalt): jaw crusher (coarse crushing) + cone crusher (medium and fine crushing).

• Medium and low hardness (limestone, sandstone): jaw crusher (coarse crushing) + impact crusher (medium and fine crushing).

• Sand making (mechanical sand production): impact crusher (VSI sand making machine).

4. What are the environmental protection measures of stone crushing plants?

• Dust control: spray system, bag filter, closed plant.

• Noise control: equipment shock absorption, soundproof cover, reasonable layout.

• Wastewater treatment: Use a sedimentation tank to circulate water during wet processing.

5. What are the uses of the finished products after crushing?

• 0-5mm: machine-made sand, used for concrete and mortar.

• 5-20mm: construction aggregate, used for roadbed and building materials.

• 20-40mm: large-scale construction projects, water conservancy projects.

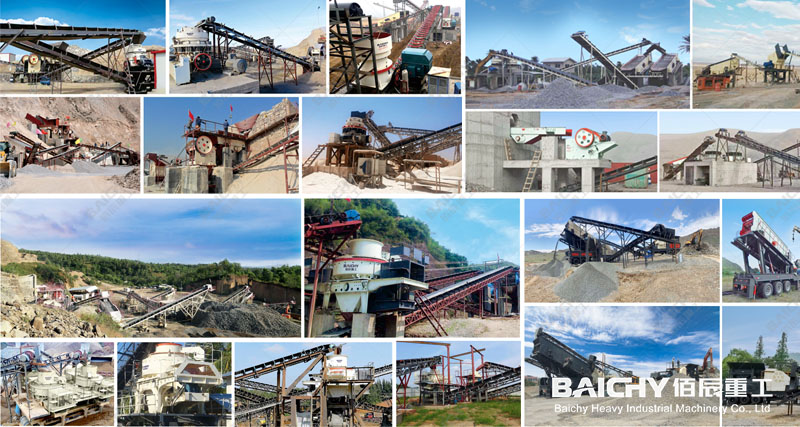

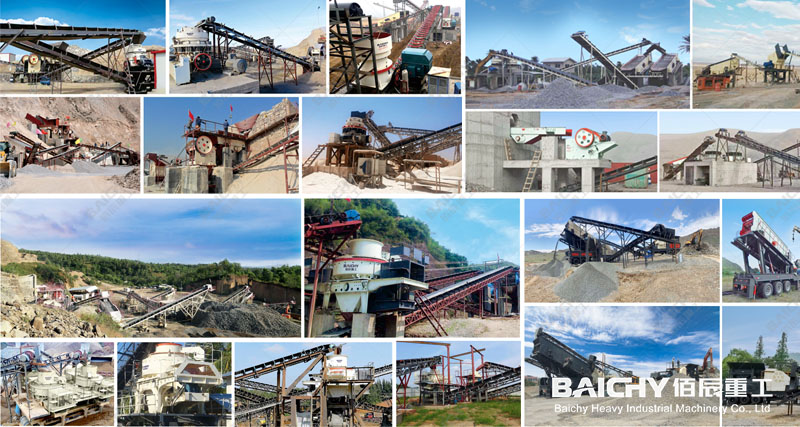

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.