Iron ore, the "food" of the steel industry, is the starting point of the beneficiation process and a key factor in determining the efficiency and cost of the entire production line. A well-designed crushing process can significantly reduce energy consumption, improve grinding efficiency, and thus enhance the final concentrate grade and recovery rate. This article will provide an in-depth and easy-to-understand explanation of the core equipment for iron ore crushing and the typical three-stage closed-circuit process.

1. Core Equipment for Iron Ore Crushing

To do your job well, you must first sharpen your tools. Selecting the right crushing equipment is fundamental to process design. Iron ore is hard and abrasive, so the equipment must possess high strength and wear resistance.

1. Primary Crushing Equipment - Jaw Crusher

◦ Role: The "pioneer" of the production line, responsible for crushing the massive raw ore (up to one meter in diameter) into fragments of approximately 250mm.

◦ Advantages: Simple structure, reliable operation, high throughput, and excellent at handling large, hard materials. Its crushing method is "extrusion," crushing the ore like two giant jaws.

2. Secondary and Tertiary Crushing Equipment - Cone Crusher

◦ Role: The backbone of the production line, receiving primary crushed material and further crushing it to less than 30mm in preparation for subsequent grinding.

◦ Advantages: High efficiency, low energy consumption, and uniform product particle size. Using a laminated crushing principle, it is ideal for crushing hard rock such as iron ore. Depending on the crushing chamber type, it can be pided into standard (secondary crushing) and short-head (tertiary crushing) types.

3. Screening Equipment - Vibrating Screen

◦ Role: The "quality inspector" and "dispatcher" of the process.

◦ Function: Screens the crushed material. Qualified fine material is sent to the next process step (such as grinding), while unqualified coarse material is returned to the crusher for further crushing (a "closed-loop" process). This effectively controls the final product particle size, prevents over-crushing, and optimizes overall efficiency.

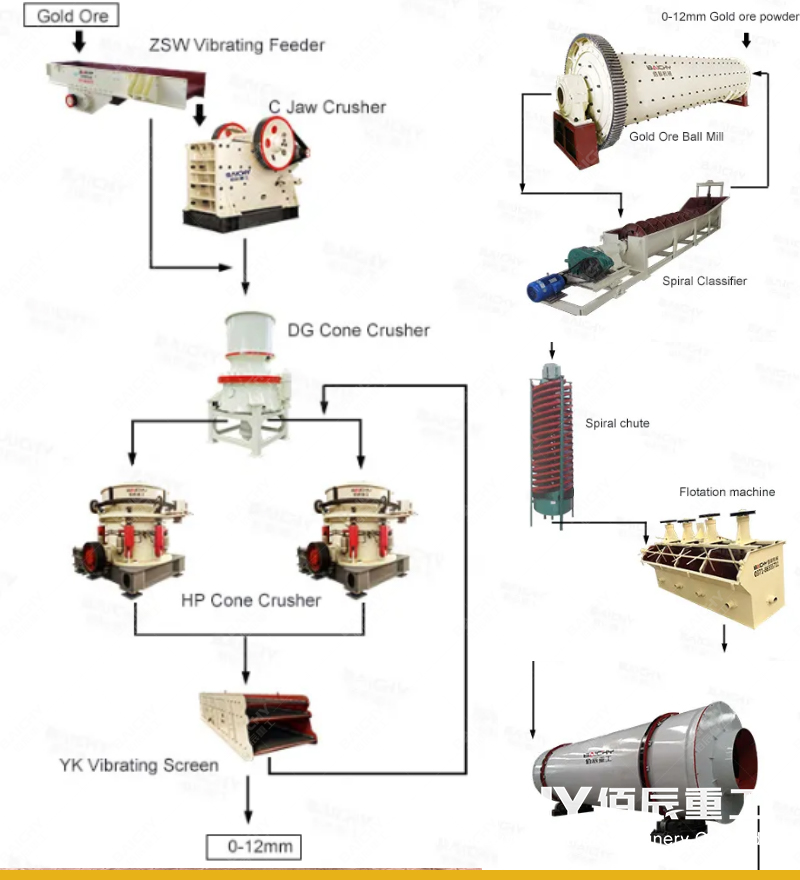

2. Typical Three-Stage, One Closed-Circuit Crushing Process

Currently, the "three-stage, one closed-circuit" process is the most classic and efficient crushing process for large and medium-sized iron ore processing plants. Its core lies in "multi-stage crushing, gradual particle size reduction, and closed-circuit screening."

• Stage 1: Coarse Crushing

Ore is fed from a feeder into a jaw crusher for initial crushing. The crushed material is transported by a belt conveyor to an intermediate stockpile or directly to the next stage.

• Stage 2: Secondary Crushing

The coarsely crushed material enters a standard cone crusher for secondary crushing, where the particle size is further reduced.

• Stage 3: Fine Crushing and Closed-Circuit Screening (Key Step)

1. The secondary crushed material is conveyed by a belt conveyor to a vibrating screen for screening.

2. The oversize (material with a particle size larger than the required size) is fed into a short-head cone crusher for fine crushing.

3. The undersize (qualified product that meets the particle size requirements) is the final crushed product and sent to the grinding plant.

4. The finely crushed material returns to the vibrating screen, forming a closed-loop cycle to ensure that all products meet the required grinding particle size.

Process Schematic:

Ore → Jaw Crusher (Coarse Crushing) → Belt Conveyor → Standard Cone Crusher (Secondary Crushing) → Belt Conveyor → Vibrating Screen → [Underscreen Pass] → Grinding

↓

[Overscreen Coarse Material] → Short-Head Cone Crusher (Fine Crushing) → (Returns to Vibrating Screen)

III. Key Points for Equipment Selection and Process Design

• Based on Ore Properties: Scientific analysis of the iron ore's hardness, particle size composition, moisture content, and gangue content is essential. This is the fundamental basis for equipment selection and process design.

• Ensure Balanced Production: The production capacity of each crushing equipment stage must be matched to avoid bottlenecks and ensure smooth operation of the entire system.

• Focus on Dust Removal and Environmental Protection: The crushing process generates a large amount of dust. Effective dust removal equipment must be installed at transfer points, crusher inlets, and other locations to meet environmental requirements. Iron ore crushing is more than a simple "smashing" process; it's a complex, interconnected system. Scientifically selecting core equipment like jaw crushers and cone crushers, along with a well-designed "three-stage, one closed-circuit" process flow, is the cornerstone of building a modern, efficient, and energy-efficient ore processing plant. We hope this article provides valuable guidance for planning and optimizing your iron ore crushing production line.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)