Impact Crusher vs. Jaw Crusher | Limestone Crushing Equipment Selection

In the design and equipment selection of limestone crushing production lines, a classic and crucial question often perplexes many mining professionals: should they choose an impact crusher or a jaw crusher? As a manufacturer of mining crushing equipment with 20 years of professional experience, we understand that there is no absolutely best equipment, only the most suitable solution. The key to selection lies in a thorough understanding of material characteristics, production needs, and matching the core advantages of the equipment. This article will provide an in-depth analysis to help you make an informed decision.

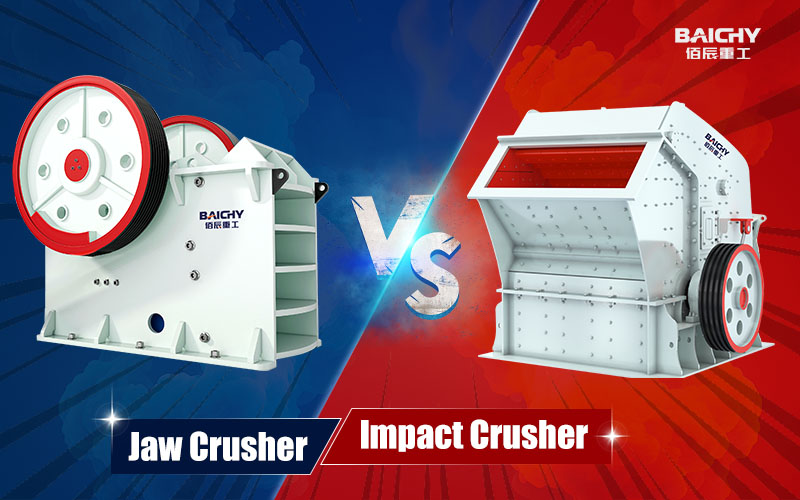

I. Core Overview: The Fundamental Differences Between the Two Crushing Principles

The first step in selection is understanding the two fundamentally different crushing methods:

PE Jaw Crusher

• Jaw Crusher: Employs the compression crushing principle. The moving and fixed jaws mimic the movement of an animal's jaws, forcefully compressing and bending the limestone located between them, thereby achieving crushing. It is like the coarse crushing warrior of the production line, specifically designed to process large pieces of raw ore, laying the foundation for the entire crushing process's capacity.

Impact Crusher

• Impact Crusher: typically referring to impact crushers or vertical shaft impact crushers: Utilizing the principle of impact crushing, a high-speed rotating rotor drives hammers to violently throw limestone against the impact plate, or through stone-on-stone or stone-on-iron methods, causing the material to break under high-speed impact. It's more like a shaping expert, excelling in medium and fine crushing and producing products with excellent particle shape.

II. Product Advantage Comparison: Each has its strengths and weaknesses

Jaw Crusher's Core Advantages:

1. Powerful Coarse Crushing Capacity: Deep crushing chamber, easily swallowing large pieces of limestone (maximum feed side length can reach over 1.5 meters), resulting in strong processing capacity.

2. Robust Structure and Strong Adaptability: Simple and reliable structure, low sensitivity to material moisture and viscosity, stable operation, and relatively simple maintenance.

3. Investment and Operating Costs: Initial investment is usually lower than impact crushers with the same processing capacity; wear parts wear patterns are more predictable; overall operating costs are advantageous in the coarse crushing stage.

Core Advantages of Impact Crusher:

1. Excellent Particle Shape and Size Control: The produced material is predominantly cubic with low needle-like and flaky content, exhibiting excellent gradation, making it ideal for producing high-quality aggregates and manufactured sand.

2. High Crushing Ratio and Flexibility: The single-machine crushing ratio is large, and the output particle size can be easily controlled by adjusting parameters such as rotor speed and impact plate gap to meet various specifications.

3. High Efficiency and Energy Saving: When performing medium-hard and lower-hardness crushing (such as limestone), its impact crushing principle has high energy utilization, potentially offering advantages in unit product power consumption.

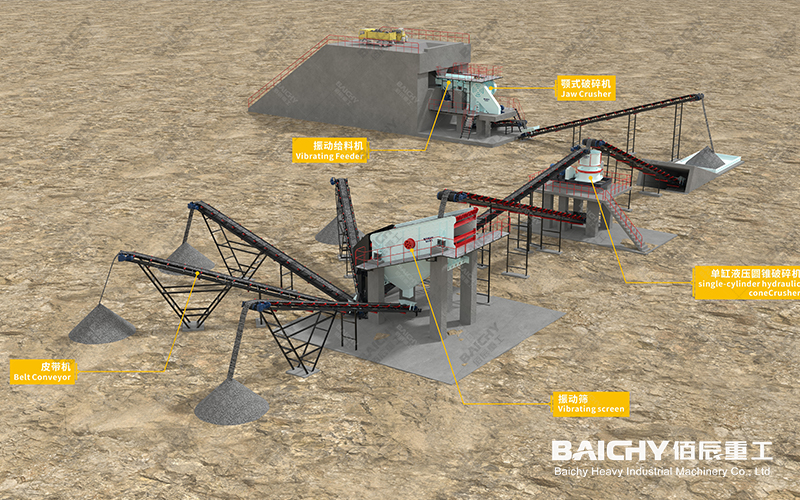

Aggregate crushing plant

III. Application Scenario Analysis: How to Match Equipment for Your Limestone Project?

• Jaw Crusher Preferred When:

◦ Large Raw Material Size: The limestone ore is large, requiring powerful primary crushing.

◦ High Demand for Production Line Stability and Durability: As the core of coarse crushing, the equipment must be robust and durable, operating stably under harsh conditions.

◦ Budget and Cost Control Sensitive: Seeking a more cost-effective solution in the coarse crushing stage.

◦ Typical Process: Typically used as the first crushing step in a combined process such as jaw crusher + impact crusher/cone crusher or jaw crusher + sand making machine.

• Impact crushers are preferred when:

◦ High requirements for finished product particle shape: The product is used in high-grade concrete aggregate, asphalt aggregate, building materials and decoration, requiring excellent cubic shape.

◦ Production of medium and fine-grained products or manufactured sand: The goal is to produce stone or high-quality manufactured sand with specifications such as 0-5mm, 5-10mm, 10-20mm.

◦ Moderate raw material hardness: Limestone is a material with a hardness of less than medium, which is very suitable for the impact crushing principle, and can give full play to its high efficiency and good particle shape characteristics.

◦ Single-stage crushing or simplified process: Under certain conditions, it can be used as a single-stage crushing equipment to simplify the process flow.

IV. Global Project Case Studies

1. A large-scale cement raw material production line in Southeast Asia: The customer's limestone raw material had a large particle size and a slightly high soil content. We configured a heavy-duty jaw crusher as the primary crusher, ensuring stable feeding and high reliability under complex operating conditions, providing a stable and qualified raw material for the subsequent grinding system.

2. A high-quality aggregate and manufactured sand project in the Middle East: The client had stringent requirements for the particle shape and gradation of the finished aggregate, intended for export to the high-end building materials market. We adopted a process of jaw crusher + impact crusher (for medium crushing and shaping) + vertical shaft impact crusher for sand production. The impact crusher excellently completed the crushing and shaping of medium-sized limestone, producing aggregate with near-perfect particle shape, fully meeting the client's standards.

V. Frequently Asked Questions (FAQ)

Q1: Can a single impact crusher complete the entire process from coarse crushing to finished product for limestone?

A: Generally not recommended. For large raw ore, direct processing with an impact crusher will lead to a sharp increase in hammer wear, resulting in decreased output and stability. The most economical solution remains a stepped combination of jaw crusher for coarse crushing + impact crusher for medium and fine crushing/shaping.

Q2: Which is more energy-efficient?

A: This depends on the specific process. For coarse crushing of large materials, the jaw crusher has a higher overall energy efficiency ratio. For medium-fine crushing of medium-sized limestone, the impact crusher's impact crushing principle may be more energy-efficient. A comprehensive system calculation is needed.

Q3: Which equipment has higher maintenance costs?

A: The two have different wear parts. Jaw crushers mainly wear the jaw plates, resulting in longer replacement cycles and relatively simpler maintenance. Impact crushers mainly wear the hammers and impact plates, which wear faster when crushing highly abrasive materials, but modern wear-resistant materials and technologies have greatly improved their lifespan. Overall maintenance costs need to be comprehensively evaluated based on the hardness of the specific material, production capacity, and the quality of the parts.

Q4: How to make a final decision?

A: We recommend that you provide detailed information on the physical properties of the limestone (compressive strength, SiO2 content, feed particle size, moisture content), expected production capacity, finished product specifications, and investment budget. As a manufacturer with 20 years of experience, we can provide you with free technology selection and solution design, and tailor the most economical and efficient crushing and screening solutions for all scenarios.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.