HP100 Cone Crusher - Advanced

In today's highly competitive sand and gravel aggregate market, efficiency, flexibility, and finished product quality are key factors determining a company's profitability. For small and medium-sized crushing plants, urban construction waste treatment, and various secondary crushing applications in mines, choosing a high-performance, stable medium-sized cone crusher is crucial. The HP100 cone crusher - Advanced model is a star product born out of this demand. With its superior performance and intelligent design, it has become the ideal choice for many mobile crushing equipment manufacturers and end-users.

Why is the HP100 Advanced model a market benchmark?

Since its introduction, the HP series cone crushers have been renowned for their high crushing efficiency and low operating costs. The HP100, as a small-to-medium tonnage model in this series, represents an Advanced upgrade that is not a simple iteration, but a comprehensive innovation from design philosophy to core components. It is precisely positioned for crushing scenarios requiring high output, excellent particle shape, and a small footprint.

Design Philosophy Overview

The core design principle of the HP100 Advanced model is to achieve maximum production efficiency within a limited space. It employs a more optimized crushing chamber design and a higher swing frequency, combined with advanced laminated crushing principles, ensuring that materials undergo multiple compressions and impacts within the chamber, thereby forming more cubic aggregates in a single pass and reducing the content of needle-like and flaky particles.

Five Reasons to Choose the HP100 Advanced Model

1. Superior Crushing Efficiency and Excellent Particle Shape: Advanced laminated crushing technology guarantees high output and high-quality finished aggregates. The perfect combination of moving cone speed and stroke results in uniform particle size distribution and a high cubic proportion, greatly enhancing the product's market value.

2. High Degree of Automation and Intelligence: The equipment is equipped with an advanced automatic control system that can monitor key parameters such as spindle position, lubricating oil temperature, and chamber pressure in real time. It achieves functions such as automatic chamber clearing, one-button adjustment of the discharge port, and remote monitoring, significantly reducing operational difficulty and labor costs.

3. Significant Energy-Saving and Environmentally Friendly Characteristics: The efficient hydraulic system and optimized mechanical structure significantly reduce unit energy consumption. Simultaneously, the excellent sealing design effectively controls dust leakage, and with the dust removal device, it meets stringent environmental protection requirements.

4. Excellent Reliability and Durability: Key components are constructed from high-strength alloy materials, resulting in a robust structure. The reliable hydraulic system not only provides over-iron protection but also makes maintenance tasks (such as replacing liners) safer and more convenient.

5. Extreme Flexibility and Adaptability: The HP100 Advanced model features a compact structure and relatively light weight, making it the perfect core for building wheeled or tracked mobile cone crushing plants. It can be quickly relocated and flexibly adapted to various complex operating conditions.

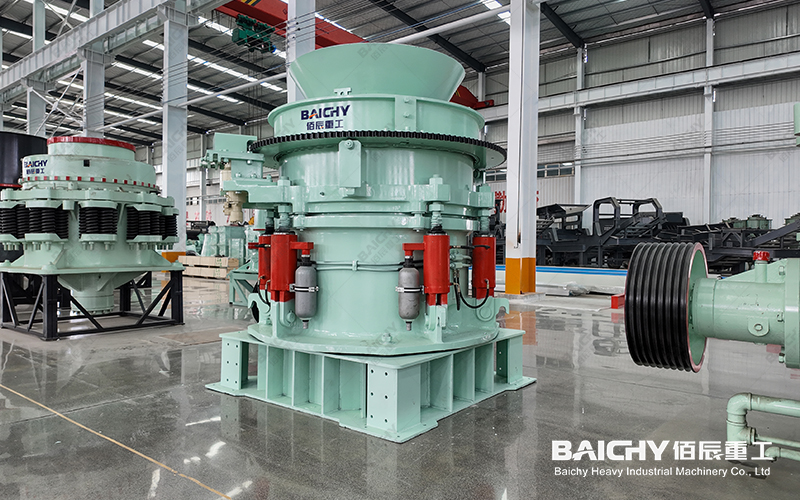

Cone crusher crushing site

Success Story: Helping Customers Create Value

One of our customers, a medium-sized granite quarry, had a previous production line that produced aggregates with a high content of needle-like and flaky particles, resulting in low market prices. After introducing a mobile crushing plant centered around the HP100 Advanced cone crusher, the situation was fundamentally reversed:

• Increased Output: Output reached 80-100 tons per hour, stably meeting demand.

• Optimized Finished Product: The finished aggregate achieved a cubic shape of over 95%, increasing the product price by 15%.

• Cost Reduction: Automated operation reduces the number of operators by two, significantly lowers equipment failure rates, and reduces maintenance costs by 20%.

Recommended Equipment: Building a Complete Production Line

To maximize the efficiency of the HP100 Advanced model, we recommend pairing it with the following equipment to form a high-efficiency mobile crushing and screening production line:

• Feeding Equipment: ZSW series vibrating feeder, ensuring uniform and continuous feeding.

• Primary Crushing Equipment: Jaw crusher mobile station (e.g., equipped with a PE600×900 jaw crusher), for primary crushing.

• Screening Equipment: 3YK series circular vibrating screen mobile station, for precise grading of aggregates.

Frequently Asked Questions (FAQ)

1. What is the maximum feed size for the HP100 cone crusher?

The maximum recommended feed size for the HP100 Advanced model is approximately 80mm. To ensure efficient and stable operation of the equipment and a long service life of the liners, oversized materials in the feed should be strictly controlled.

2. What is the maintenance cycle and complexity of the equipment?

Thanks to intelligent monitoring and hydraulic clearing functions, daily maintenance is very simple. The main maintenance tasks focus on regularly checking the lubrication system's filter element and periodically replacing the wear-resistant liners. The automated system will indicate maintenance times, greatly reducing the risk of unplanned downtime.

3. Is it suitable for processing high-hardness materials such as basalt and granite?

Perfectly suitable. The HP100 advanced model is designed for secondary or tertiary crushing of medium-to-high hardness materials. Its robust structure and optimized cavity shape can effectively crush materials such as granite, basalt, and river pebbles, but it is important to select appropriate wear-resistant parts materials (such as high-manganese steel or higher-grade alloy steel).

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!