Types of Crushers: Cone, Jaw, Impact, Gyratory and More

In mining, aggregate production, and building demolition, crushers are core equipment, and their type and performance directly impact production efficiency and operating costs. As a manufacturer of mining crushing equipment with 20 years of professional experience, we are committed to providing comprehensive solutions for global customers. This article will provide an in-depth analysis of mainstream equipment such as cone crushers, jaw crushers, impact crushers, and gyratory crushers to help you make informed choices based on your needs.

Product Advantages

• Jaw Crusher: Robust structure, suitable for primary crushing, strong capacity for handling high-hardness materials, large crushing ratio, and easy maintenance.

• Cone Crusher: Utilizes the principle of layered crushing, producing excellent particle shape, low energy consumption, suitable for medium and fine crushing, and highly automated.

• Impact Crusher (including vertical shaft impact crusher): Suitable for medium-soft materials, producing excellent finished particle shape, capable of "stone-on-stone" or "stone-on-iron" crushing, with flexible adjustment of discharge particle size.

• Gyratory Crusher: Large processing capacity, strong continuous operation, suitable for primary crushing in large mines, stable operation, and high output.

Our equipment is manufactured using wear-resistant materials and equipped with an intelligent control system to ensure efficient and stable operation, reducing total lifecycle costs.

Application Scenarios

• Metal Mines: Gyratory crushers are used for primary crushing, while cone crushers are used for medium and fine crushing, producing uniform particles for mineral processing.

• Sand and Gravel Aggregate Production: Jaw crushers, cone crushers, and impact crushers operate in combination to produce aggregates of various grades to meet the needs of construction and highway industries.

• Construction Waste Recycling: Mobile jaw crushers or impact crushers enable on-site crushing, resource utilization, and environmental protection and economic efficiency.

• Industrial Mineral Processing: Fine crushing equipment processes limestone, gypsum, etc., meeting the requirements of the chemical and building materials industries.

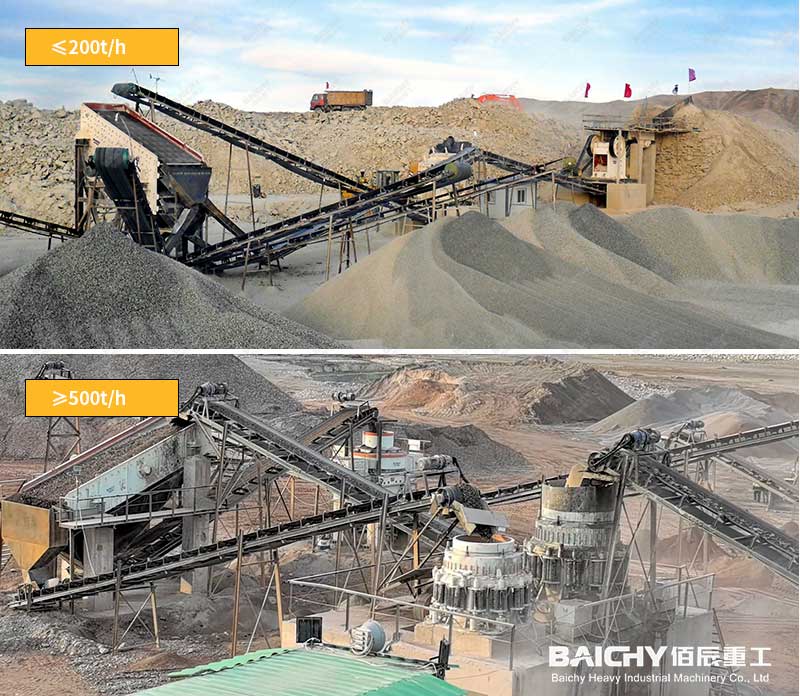

Medium-sized-production-line-vs.-large-sized-production-line

Project Cases

In a large iron ore project in Southeast Asia, we configured a gyratory crusher (primary crushing) + cone crusher (secondary crushing) production line for the client, achieving a production capacity of 2000 tons per hour with an equipment utilization rate exceeding 95%, helping the client increase capacity by 30%. In an aggregate plant in North America, multiple impact crushers were used to produce high-quality manufactured sand, replacing natural sand and obtaining green certification.

FAQ

Q: How to choose the type of crusher?

A: Consider the material hardness, feed size, required output, and finished product requirements. For example, jaw crushers or cone crushers are preferred for high-hardness materials, while impact crushers are used to achieve better particle shape.

Q: Is equipment maintenance complex?

A: We offer modular designs, key components are easy to replace, and are equipped with remote monitoring systems for predictive maintenance, reducing downtime.

Q: Can you provide customized solutions?

A: Yes, we can design fixed or mobile end-to-end solutions based on site conditions, capacity requirements, and budget, and provide installation and training services.

Choosing us means choosing experience and innovation—20 years of focus, helping global mining clients achieve sustainable growth.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.