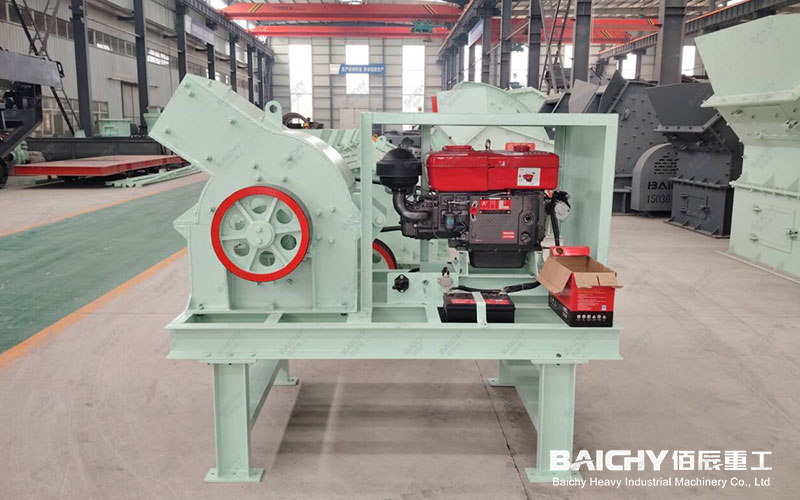

Gold Ore Hammer Mill With Diesel

In gold mining exploration, initial mining, or operations in remote areas, a stable power supply is often a significant challenge. Traditional fixed crushing production lines, while efficient, are limited by the power grid and cannot cover all mining areas.

The diesel-powered gold ore hammer crusher was created to address this pain point. It integrates the powerful crushing capabilities of a hammer crusher with the self-contained power of a diesel engine, forming a mobile, independent, and efficient crushing unit. It is particularly suitable for coarse and medium crushing of raw ore in small and medium-sized gold mines, vein deposits, or scattered mining points.

The diesel-powered gold ore hammer crusher is essentially a mobile crushing system based on a trailer or crawler-mounted mobile station. Its core is driven by a high-performance diesel engine, providing power to the heavy-duty hammer crusher. The hammer crusher uses high-speed rotating hammers to impact, shear, and collide with the gold ore, causing it to cleave along natural fissures and efficiently crush it to the desired particle size (usually adjustable, ranging from 25-40mm), preparing it for subsequent grinding and gold extraction processes. The entire system typically includes a feeder, crushing host, diesel power pack, discharge conveyor belt, and centralized control system, achieving high integration and rapid relocation.

Gold Ore Hammer Mill With Diesel

Core Advantages of the Diesel-Powered Gold Ore Hammer Crusher:

1. Unparalleled Mobility and Site Adaptability: Without relying on an external power grid, it can quickly access new mining areas, mountainous regions, riverbeds, and other complex terrains, enabling crushing wherever you go.

2. Powerful Performance and High Crushing Ratio: The high-power diesel engine provides stable and abundant power, ensuring the hammer crusher can effectively process high-hardness gold ore. The hammer crusher itself has a very high crushing ratio, capable of crushing large chunks of raw ore to smaller sizes in a single pass, simplifying the process flow.

3. Flexible Investment and Rapid Commissioning: Compared to building a fixed crushing production line, this equipment has lower investment costs and requires no foundation construction. It can be quickly put into production after arrival and connection, shortening the return on investment cycle.

4. Reliable Operation and Easy Maintenance: Diesel engine technology is mature, and fuel is readily available; the hammer crusher has a relatively simple structure, and wear parts (such as hammer heads and liners) can be replaced quickly, making it suitable for use in mining areas with limited maintenance facilities.

5. Strong Suitability: The hammer crusher has excellent crushing performance for gold ore with medium hardness or below and not extremely high silicon content (such as quartz vein type gold ore), effectively liberating minerals and facilitating the recovery of gold elements.

Ore Processing Gold Stone Hammer Mill

Application Case

Our client, a medium-sized gold mine located in West Africa, has scattered mining areas and an unstable power grid. In 2022, they introduced our HCPS-1200 diesel-powered mobile hammer crushing station. This equipment is equipped with a large 1200×1000mm hammer crusher, driven by a 400 horsepower diesel engine. In practical application, the equipment operated alternately between three mining points 5 kilometers apart, with an average operating time of 2 months at each point. It successfully crushed raw gold ore with a particle size of approximately 600mm to ≤30mm material, with a stable processing capacity of 80-100 tons/hour, fully meeting the feeding requirements of their downstream ball mill. This increased the initial mining efficiency of the mine by approximately 40% and saved significant costs associated with power supply.

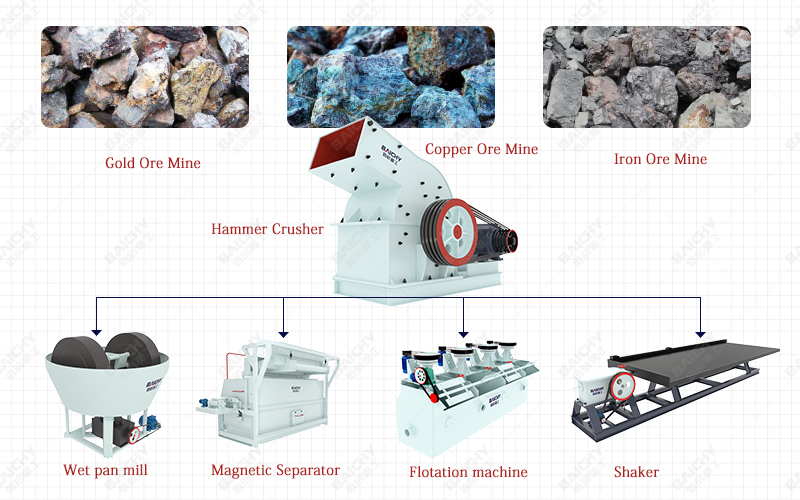

Related Equipment Recommendations

Based on the complete gold ore beneficiation process, after considering the diesel-powered hammer crusher, clients may also consider the following equipment to form a more efficient production line:

Jaw Crusher (Diesel Powered): As the preferred choice for primary crushing, it handles larger raw ore, forming a two-stage mobile crushing system with the hammer crusher.

Mobile Cone Crusher: If finer and better-shaped products are required, it can be used for secondary and tertiary crushing.

Mobile Vibrating Screen: Used in conjunction with the crusher to achieve immediate screening and classification of materials, improving overall efficiency.

Diesel-Powered Gold Panning/Beneficiation Equipment: Such as centrifugal gold concentrators and shaking tables, to form a complete mobile gold beneficiation unit.

Frequently Asked Questions (FAQ)

Q: What are the fuel consumption and operating costs of a diesel-powered hammer crusher?

A: Fuel consumption depends on the equipment model, load rate, and ore hardness. For example, our medium-sized equipment consumes approximately 20-30 liters per hour under full load. Although fuel costs are higher than electricity, the savings in power grid construction costs and the resulting operational flexibility usually make it more cost-effective in remote mining areas.

Q: What size gold ore can it process?

A: The feed size depends on the specific model, but it can typically handle large ore pieces with side lengths of 400mm to 600mm. When purchasing, you need to match the model to the maximum size of the raw ore in your mining area.

Q: How is the equipment's environmental adaptability? Is it resistant to high temperatures and humidity?

A: Our equipment is designed for harsh mining environments. The diesel engine is equipped with an efficient cooling and air pre-filtration system, and key components are treated for rust prevention. It can operate stably in ambient temperatures from -20℃ to 45℃ and is adapted to certain humid climates.

Q: What is the lifespan of the hammer heads? Is replacement complicated?

A: The lifespan of the hammer heads is closely related to the abrasiveness of the ore. When processing moderately abrasive gold ore, a set of high-manganese steel or alloy steel hammer heads can last for 300-600 hours. Our equipment features a quick-change design, allowing for the replacement of a complete set of hammer heads in typically 2-3 hours, greatly reducing downtime.

Q: Does the equipment require a professional operation and maintenance team?

A: Operators with basic knowledge of diesel engine maintenance and crusher operation are required. We provide comprehensive operation and maintenance training, along with detailed Chinese manuals and video tutorials, to ensure that the customer's team can quickly get started.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.