Wet Ball Mill for Metal Ores and Non-ferrous Metals Wet Mill

Wet Ball Milling: The Cornerstone of Mineral Processing

In the beneficiation of metallic ores (such as iron, copper, lead, and zinc) and non-ferrous metals (such as tungsten, tin, and molybdenum), crushing and grinding are crucial steps in releasing valuable minerals and achieving liberation of inpidual minerals. As the core equipment process in the grinding stage, the efficiency of wet ball milling directly affects the indicators of subsequent separation (such as flotation and magnetic separation) and the overall economic benefits of the beneficiation plant. Through the synergistic action of steel balls, materials, and water, it further grinds the crushed ore to a suitable particle size for beneficiation, creating optimal conditions for mineral separation.

| Key Words | Wet Ball Mill for Metal Ores and Non-ferrous Metals Wet Milling |

|---|---|

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Why Choose Wet Ball Milling? In-depth Analysis of its Core Advantages

Compared to dry ball milling, wet ball milling is more widely used in the field of metallic mining due to its irreplaceable multiple advantages.

1. Higher Grinding Efficiency and Finer Particle Size

The water medium plays a role in "lubrication" and "transmission" within the mill. It effectively removes fine particles, reducing over-grinding and the "cushioning" effect, allowing the grinding media to more effectively impact and grind coarser particles, resulting in finer and more uniform product particle size. This is particularly suitable for flotation processes requiring fine grinding.

2. Superior Working Environment and Lower Operating Costs

Wet grinding generates virtually no dust, significantly improving the workshop operating environment and meeting environmental protection requirements. Simultaneously, water helps materials flow within the mill, reducing energy consumption for material transport; overall power consumption is typically lower than dry grinding under equivalent conditions.

3. Suitable for Subsequent Wet Mineral Processing

Most metallic minerals are separated using wet processes such as flotation and gravity separation. The slurry produced by a wet ball mill can be directly or after classification into the next process, ensuring smooth process integration without the need for additional dewatering or pulping steps, simplifying process configuration.

Wet Ball Mill for Metal Ores and Non-ferrous Metals Wet Milling

Success Stories: 20 Years of Professional Manufacturing Experience

With 20 years of experience in mineral processing equipment design and manufacturing, we have provided efficient and reliable wet ball mill solutions for hundreds of mining projects worldwide.

• Case Study 1: A large copper mine in East China. A Φ3.6×6.0m wet grate ball mill was installed, with a stable throughput of 180-200 tons/hour. This milled the copper ore from -12mm to -0.074mm (70%), providing ideal slurry conditions for copper flotation and increasing copper recovery by approximately 2%.

• Case Study 2: A tungsten-tin mine project in Africa. Considering the ore properties, we recommended a closed-circuit grinding system consisting of a wet overflow ball mill and a spiral classifier. This configuration effectively controlled over-grinding, improved the liberation of inpidual tungsten-tin minerals, and ultimately exceeded the client's expectations in terms of concentrate grade and metal recovery.

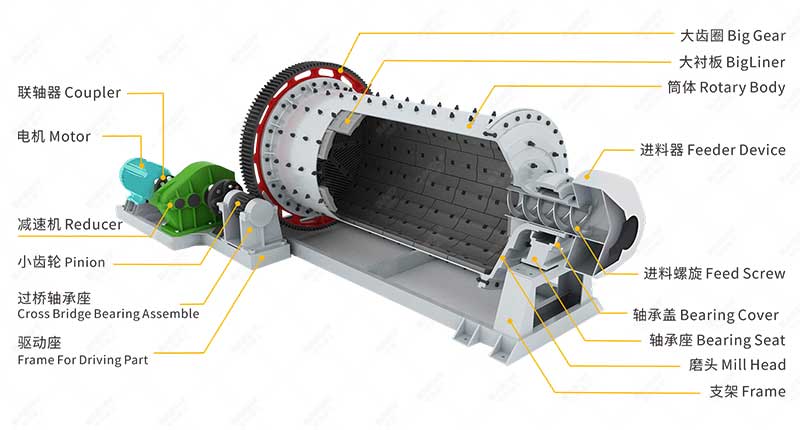

Ball mill structure diagram

Equipment Selection Recommendation: Key Considerations for Matching Needs

Selecting a suitable wet ball mill requires comprehensive consideration of ore properties, processing capacity, product fineness, and process flow.

1. Mill Type Selection: Grid-type ball mills offer fast discharge speeds, minimal over-grinding, and high throughput, suitable for coarse or single-stage grinding; overflow-type ball mills have a simpler structure and produce finer products, commonly used for two-stage or fine grinding operations.

2. Specifications: The mill cylinder diameter and length are determined based on the designed throughput. We offer various specifications from Φ0.9m to Φ4.5m.

3. Core Components:

◦ Liners: We offer a variety of materials including high-manganese steel, rubber, and magnetic liners to accommodate different abrasive ores, protecting the cylinder and improving grinding efficiency.

◦ Grinding Media: From high-chromium steel balls to forged steel balls, we can provide professional advice to optimize the ball ratio and reduce consumption per unit.

Frequently Asked Questions (FAQ) about Wet Ball Mills

1. How is the throughput capacity of a wet ball mill calculated?

Processing capacity depends on ore grindability, feed and product particle size, mill model, and operating conditions. Basic data is typically obtained through Bond's index testing, followed by precise calculations using empirical formulas. We offer free selection testing and calculation services.

2. How to control the fineness of wet-milled products?

Product fineness is primarily controlled by adjusting the mill's feed rate, grinding concentration (slurry concentration), and circulating load. Adding classifying equipment (such as hydrocyclones) to form a closed-circuit grinding system is the most effective method to achieve stable and qualified fineness.

3. What is the lifespan of wear parts in a wet ball mill? Is replacement complex?

The main wear parts are liners and steel balls. Lifespan varies depending on ore hardness and corrosiveness; liner lifespan typically ranges from 6 to 24 months. Our mills are designed with ease of maintenance in mind, employing modular liner designs and providing detailed replacement tools and instructions to minimize downtime.

Wet ball milling serves as a bridge between crushing and sorting, and is a crucial process determining the recovery rate and economic benefits of metal ores and non-ferrous metals. Choosing an equipment partner with extensive experience who can provide comprehensive support from design and manufacturing to commissioning is essential. We sincerely invite mining professionals worldwide to exchange ideas and collaborate, leveraging our 20 years of expertise to help your concentrators achieve higher efficiency.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.