In industries such as mining, building materials, and metallurgy, we often need to process huge rocks into sand and gravel aggregates of different sizes. In this transformation from large to small, the cone crusher plays a crucial role, hailed as the core equipment for medium and fine crushing stages. But have you ever wondered how this steel behemoth accomplishes its crushing tasks so efficiently and reliably?

Today, we'll delve into the working principle of the cone crusher, revealing the scientific secrets behind its efficient crushing.

Hydraulic Cone Crusher PDF,Download ↓↓↓

I. Core Philosophy: Layered Crushing, Overcoming Hardness with Softness

Unlike jaw crushers, which rely on hard-on-hard impact, the core concept of the cone crusher is more ingenious—layered crushing. Imagine cracking a walnut with a hammer; fragments might fly everywhere. But if you hold the walnut in your palm and apply even force, it will crack completely. Layered crushing is the latter; it uses continuous static pressure and compressive force to repeatedly crush the material between materials and between the material and the crushing wall.

The advantages of this method are obvious:

• Good product particle shape: Low content of needle-like and flaky particles, more cubic particles, and higher strength.

• High efficiency and low energy consumption: Energy is mainly used for crushing the material itself, resulting in minimal loss.

• Low wear: Reduces direct impact between metal and material, extending the life of vulnerable parts.

II. Detailed Explanation of Working Principle: The Art of Crushing Between Movement and Stillness

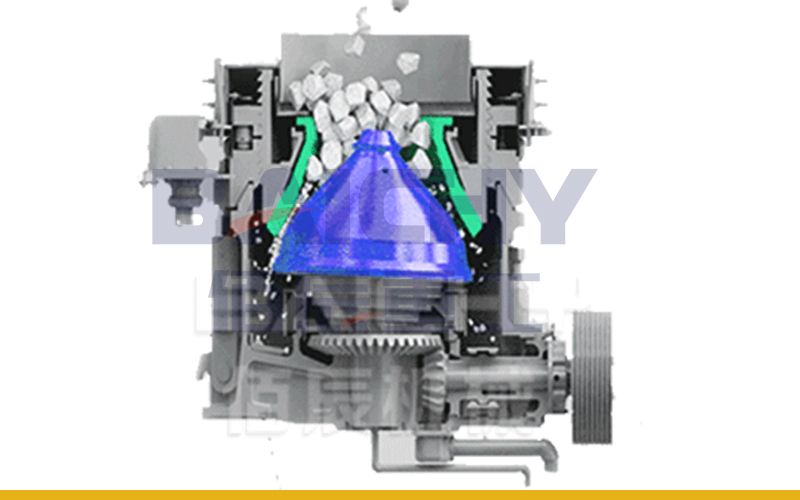

Although the structure of a cone crusher is complex, its working principle can be clearly understood through the coordinated movement of several core components.

Main Components:

1. Moving Cone: The core working component of the equipment, driven by the main shaft, oscillates regularly.

2. Fixed Cone: Fixed to the frame, forming the crushing chamber together with the moving cone.

3. Eccentric Sleeve: Fitted on the main shaft, its rotation is the engine driving the oscillation of the moving cone.

4. Crushing Chamber: Formed by the space between the moving and fixed cones, where the material is crushed.

Working Process (Three Steps):

Step 1: Feeding The material to be crushed falls into the crushing chamber from the top feed port. At this point, driven by the eccentric sleeve, the moving cone undergoes a unique oscillating motion. It doesn't simply rotate; rather, its centerline moves in a circular motion around a point, causing the surface of the moving cone to alternately approach and move away from the fixed cone.

Step Two: Compression Crushing

As the moving cone oscillates closer to the fixed cone, the space between them (the crushing chamber) narrows, applying immense compressive force to the material within. The material is first pre-crushed in the upper part of the crushing chamber (where the feed opening is larger). Subsequently, under the combined action of gravity and the continuous oscillation of the moving cone, the crushed material moves downwards, entering a narrower area in the lower part of the crushing chamber.

Here, the layered crushing effect reaches its peak. Smaller material particles are surrounded by larger particles, and under immense compressive force, the materials squeeze and grind against each other, achieving highly efficient crushing. This ensures that each compression acts on multiple material particles, rather than a single-point impact.

Step 3: Discharge When the material is crushed to a sufficiently small size, smaller than the minimum gap between the moving and fixed cones at the bottom (i.e., the discharge port), it is smoothly discharged under gravity, completing one full crushing cycle.

Animated Visualization: Imagine a spinning top slowly revolving (precession) at the bottom of a bowl. The surface of the top (moving cone) continuously rubs against and squeezes the inner wall of the bowl (fixed cone), and the beans (material) inside are crushed in this process.

III. Key Advantages: Why is it the best choice for medium and fine crushing?

1. High efficiency and low energy consumption: The layered crushing principle allows it to achieve a much higher output than other crushing methods with the same power consumption.

2. Excellent product particle shape: The produced aggregate particles are uniform with a high cubic content, making it particularly suitable for high-standard concrete aggregate production.

3. High degree of automation: Modern cone crushers are usually equipped with hydraulic systems, which can easily adjust the discharge port size, realize overload protection (automatic release when uncrushable materials enter) and clearing function, greatly improving the stability and safety of operation.

4. Stable and Reliable Operation: Robust structural design suitable for continuous, high-intensity crushing operations.

IV. Application Scenarios: Areas Where It Shines

Cone crushers are mainly used for the medium and fine crushing stages of materials with high hardness, such as:

• Crushing of high-hardness ores such as granite and basalt.

• Mineral processing in metal mines such as iron ore and copper ore.

• Production lines in the building materials industry with strict requirements for sand and gravel particle shape.

The cone crusher does not rely on brute force, but is a smart player that understands the principle of using minimal force to achieve maximum effect. Through the ingenious principle of layered crushing, it transforms powerful force into continuous and uniform static pressure, thereby efficiently and economically producing high-quality sand and gravel aggregates, silently supporting the foundation of modern infrastructure construction. Understanding its working principle allows us to better utilize this powerful equipment and contribute to the development of various industries.

For a more in-depth discussion of cone crushers (such as multi-cylinder hydraulic cone crushers), we can continue to explore this topic.