The superior performance and long lifespan of every smooth and sturdy highway and every high-speed railway are not solely due to the surface asphalt or concrete, but rather to the underlying base materials. Among these, crushed stone aggregate produced by quarries plays a crucial skeleton role.

As the load-bearing layer of a road, the particle shape, gradation, compressive strength, and stability of the crushed stone aggregate directly determine the road's load-bearing capacity, durability, and maintenance costs.

Therefore, selecting a high-efficiency, stable quarry crusher with excellent output quality is a primary step to the success of a road construction project.

I. Stringent Requirements for Crushed Stone Aggregates in Road Construction: More Than Just Crushing

Unlike ordinary building stone, road crushed stone aggregate has much more refined and stringent standards. A qualified crusher must meet the following core requirements:

1. Strict Particle Shape and Grading: Ideally, the aggregate should be cubic or multi-faceted, as this provides strong interlocking forces between particles, forming a highly stable base layer. The content of flaky and needle-like particles must be strictly controlled, otherwise it will reduce compaction density and resistance to deformation. Meanwhile, a continuous gradation from coarse to fine ensures the mixture reaches maximum density.

2. High Capacity and Continuity: Road projects typically have tight schedules and large material consumption, requiring crushers to continuously and stably provide hundreds or even thousands of tons of aggregate per hour. Any unexpected downtime can lead to the shutdown of downstream mixing plants, causing significant economic losses.

3. Product persity: A complete road structure requires aggregates of different specifications; for example, the dimensions of stones required for the base course, subbase course, and surface course differ. An excellent crushing production line should be able to flexibly adjust to produce multiple specifications of products, maximizing resource value.

II. Core Equipment Recommendations: Crushing Solutions for Different Working Conditions

Based on 20 years of industry experience, we understand that there is no single, foolproof solution. For different stages of road construction and the characteristics of the aggregate, we recommend the following core equipment combination:

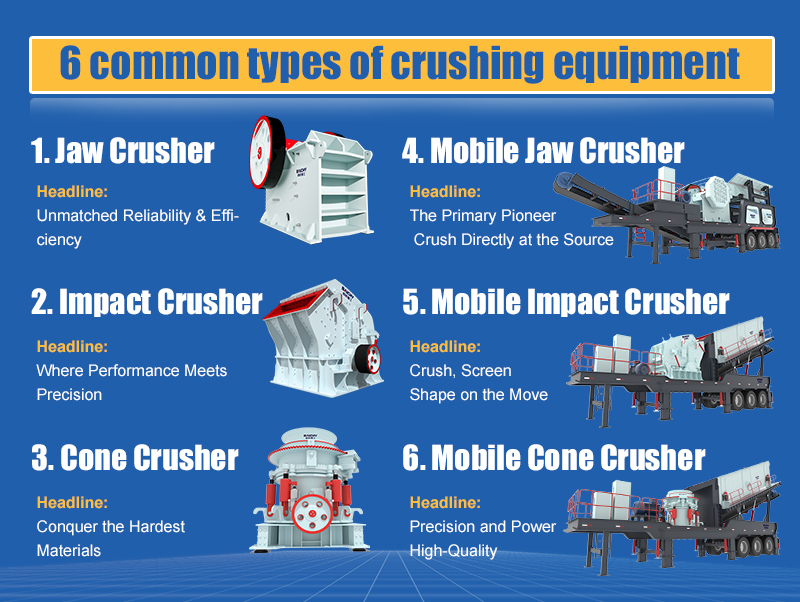

• Primary Crushing Jaw Crusher: The Robust and Durable Pioneer

◦ Role: Responsible for the first coarse crushing of large blocks of raw stone obtained from quarry blasting. It is the entry point of the entire production line, bearing the greatest impact and wear.

◦ Advantages: Simple structure, reliable operation, convenient maintenance, and large processing capacity. Our jaw crusher uses high-strength steel and a deep cavity design, providing powerful crushing force and easily handling various hard rocks, laying a solid foundation for subsequent medium and fine crushing.

• Medium and Fine Crushing Cone Crusher / Impact Crusher: The Refined Shaper

◦ Cone Crusher: Suitable for crushing medium to high hardness, highly abrasive rocks such as granite, basalt, and river pebbles. It uses the principle of layered crushing, producing aggregates with uniform particle shape and low needle-like and flaky content, making it an ideal choice for high-standard highway base course aggregates. Although the initial investment is relatively high, its wear-resistant parts have a long lifespan and long-term operating costs are low.

◦ Impact Crusher: More suitable for crushing medium-to-low hardness materials such as limestone and concrete. It utilizes impact energy for crushing, producing cubic particles with sharp edges and a rough surface that facilitates asphalt bonding, making it a preferred aggregate for high-quality asphalt concrete surface layers. It boasts advantages such as low investment cost, good shaping effect, and easy maintenance.

• Sand Making and Shaping Impact Crusher (Sand Making Machine): The Finishing Touch

◦ Role: Used to produce high-quality manufactured sand (0-5mm), used to adjust the gradation of aggregate mixtures or as fine aggregate in cement concrete. Its stone-on-stone or stone-on-iron principle effectively improves the particle shape of the sand and enhances the overall aggregate quality.

III. Providing Guarantees Beyond the Equipment Itself

Choosing us means you get more than just a cold machine; you get a comprehensive solution based on extensive project experience.

• Customized Production Line Design: Our engineers will visit your site to design the most economical and efficient process flow and equipment layout based on the properties of your raw stone, expected output, finished product requirements, and site conditions.

• Full Life Cycle Cost Management: We focus on the total cost of equipment throughout its entire lifespan, not just the purchase price. We provide high-quality, long-life wear-resistant parts and reduce unit energy consumption through optimized design, helping you truly improve efficiency and reduce costs.

• Timely After-Sales Service: We have a global service network and spare parts inventory, providing rapid installation guidance, commissioning training, and technical support to ensure your project proceeds smoothly and without worries.

Roads are the arteries of economic development, and high-quality crushed stone aggregate is the strong foundation of these arteries. As your trusted mining crushing partner, we are willing to leverage our 20 years of professional experience to provide the most robust and reliable crushing equipment support for your highway, national highway, provincial highway, and other road construction projects. Let us join hands to build every quality road to the future from the source.