Ball Mills | High-Efficiency Grinding Process

What is Ball Milling?

In the field of mineral processing, ball milling is a crucial and widely used crushing technology. As a manufacturer of mining crushing equipment with 20 years of experience, we deeply understand the core position of the ball milling process in the mineral processing flow. Simply put, ball milling is the process of crushing materials to a target particle size by using a rotating cylinder to drive internal grinding media such as steel balls, utilizing impact and grinding forces. Whether it's metal ores, non-metallic ores, or industrial minerals, the ball mill is the main force in achieving mineral liberation and creating conditions for subsequent separation.

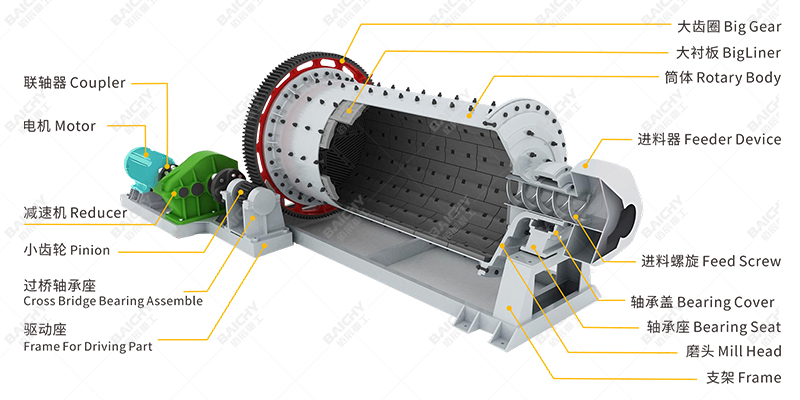

Ball mill structure diagram

I. Overview of the Ball Milling Process: How Does It Work?

A standard ball mill mainly consists of a rotating cylinder, a feeding end, a discharge end, a transmission device, and the grinding media (such as steel balls and steel rods). Its working principle is based on the synergistic effect of centrifugal force and friction:

- The cylinder rotates at a low speed, lifting the grinding media to a certain height before dropping them, generating strong impact crushing.

- The sliding and rolling between the media and between the media and the material produce continuous grinding.

- The material is continuously subjected to impact and grinding inside the cylinder, and its particle size changes from coarse to fine, finally reaching the process requirements.

According to the discharge method, it is mainly pided into grate-type ball mills and overflow-type ball mills, which are suitable for coarse grinding and fine grinding operations, respectively.

II. Advantages of the Ball Milling Process

Why has the ball milling process remained dominant for centuries? Its core advantages are significant:

1. High crushing efficiency and large processing capacity: Especially suitable for large-scale continuous production of medium-hard and harder ores.

2. Uniform and easily adjustable product particle size: By controlling the grinding concentration, media ratio, and grinding time, stable products that meet the separation requirements can be obtained.

3. Extremely wide applicability: It can handle almost all types of ores and materials, with strong adaptability.

4. Reliable operation and simple maintenance: The structure is relatively simple, and the operation is easy, making it the backbone of modern mineral processing plants. 5. Easy to implement automated control: Combined with modern sensors and PLC systems, it allows for optimal control of the grinding process, reducing energy consumption.

Ball mill customer site

III. Case Studies and Technological Evolution Based on 20 Years of Experience

With two decades of deep industry experience, we have witnessed the continuous innovation of ball mill technology. For example, the energy-saving ball mill solution we provided to a large domestic iron mine:

- Challenge: The original equipment had high energy consumption, unstable product particle size, and serious over-grinding.

- Solution: We adopted our independently developed waveform liner and classification liner, optimizing the shape of the lifting bars inside the cylinder and improving the movement trajectory of the grinding media. At the same time, we precisely matched the grading ratio of large and small steel balls.

- Results: Under the same processing capacity, the mill power consumption was reduced by approximately 15%, the target particle size yield increased by 8%, and the over-grinding rate decreased significantly, bringing considerable economic benefits to the customer.

This case demonstrates the transformation from simple equipment manufacturing to high-efficiency and energy-saving grinding system solutions, which is the core value of our 20 years of technological accumulation.

IV. Ball Mill Selection and Related Equipment Recommendations

Choosing a suitable ball mill is a prerequisite for efficient production. Key considerations for selection include:

- Ore properties: Hardness, particle size, grindability, and moisture content.

- Production capacity requirements: Tons processed per hour.

- Product fineness requirements: Coarse grinding or fine grinding.

- Process flow configuration: Open-circuit grinding or closed-circuit grinding.

Related equipment recommendations:

- Supporting classification equipment: Hydrocyclone or high-frequency fine screen, forming a closed-circuit grinding system to improve efficiency.

- Pre-processing equipment: Jaw crusher, cone crusher, providing qualified feed for the ball mill through more crushing, less grinding.

- Subsequent optimization equipment: Stirred mill or vertical mill, used for ultra-fine grinding or regrinding operations.

A scientifically configured crushing and grinding system is the cornerstone of maximizing return on investment in mining.

V. Frequently Asked Questions (FAQ)

Q1: What are the main differences between a ball mill and a rod mill?

A1: The core difference lies in the grinding media. Ball mills use steel balls, primarily relying on impact and grinding, resulting in finer product particle sizes, suitable for fine grinding. Rod mills use steel rods, with linear contact between the media, providing selective crushing action, resulting in a more uniform product particle size and less over-grinding, often used for coarse grinding or brittle materials.

Q2: How to reduce ball mill energy consumption?

A2: Reducing energy consumption is a systemic engineering effort. Key measures include: 1) Ensuring the feed material particle size meets the crush more, grind less requirement; 2) Optimizing the steel ball grading and filling rate; 3) Using energy-efficient liners (such as corrugated liners, classifying liners); 4) Adopting a high-efficiency transmission system (such as permanent magnet synchronous motors); 5) Achieving automatic optimal control of grinding concentration and circulating load.

Q3: What are the key points of daily maintenance for a ball mill?

A3: Daily maintenance is crucial for ensuring stable operation: 1) Regular inspection: fasteners, lubrication system (bearings, gears), liner bolts; 2) Timely replacement: severely worn liners, worn or failed steel balls; 3) Maintain cleanliness: ensure the cooling and lubrication systems are unobstructed; 4) Record operating data: current, temperature, noise, and troubleshoot any abnormalities promptly.

Ball milling, as a long-standing core technology in the field of mineral processing, its efficiency and stability directly affect the economic benefits of the entire beneficiation plant. As an experienced equipment manufacturer, we not only provide reliable and durable ball mills, but are also committed to providing customers with comprehensive solutions covering process design, equipment selection, energy saving optimization, and intelligent control. In the future, we will continue to promote grinding technology towards a more efficient, energy-saving, and intelligent direction, creating greater value for global mining customers.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.