In modern sand and gravel aggregate production lines, raw materials mined from mines, after crushing and screening, often contain a lot of impurities such as mud and stone powder. These impurities seriously affect the quality of the finished sand, and consequently, the strength of concrete and the quality of the project. Therefore, a crucial cleaning process becomes particularly important, and the spiral sand washer is the core equipment in this process.

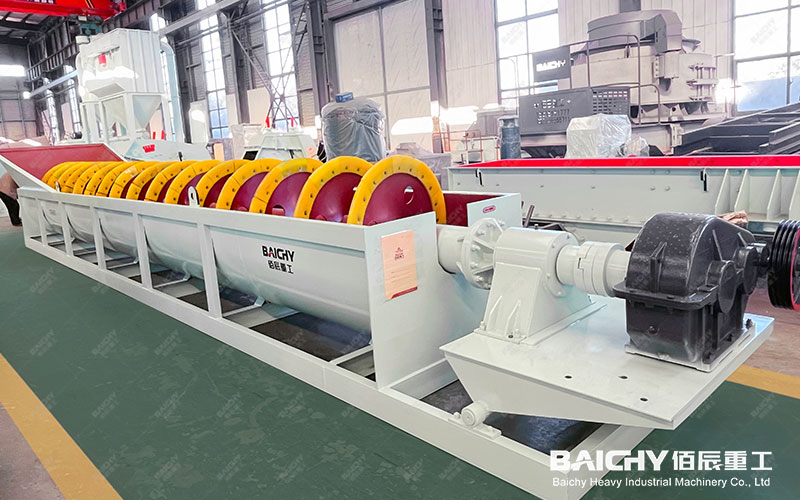

I. What is a Spiral Sand Washer?

A spiral sand washer, also known as a spiral stone washer, is a washing and screening device that uses a spiral device to agitate, wash, and dewater sand and gravel materials. It utilizes the principle that particles of different sizes and densities settle at different speeds in water. Through the continuous agitation of the spiral blades, it effectively separates sand and gravel from mud and stone powder, thereby obtaining clean, well-graded, high-quality construction sand.

II. How Does a Spiral Sand Washer Work?

Its working principle is intuitive and efficient:

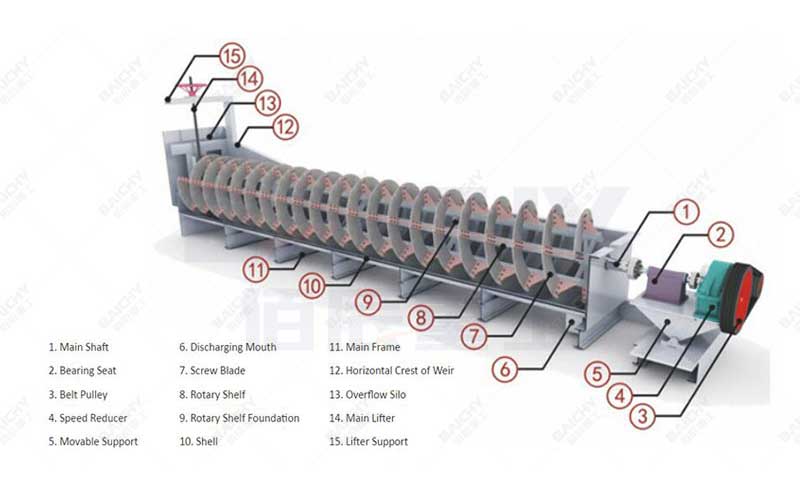

1. Feeding: The sand and gravel raw material mixed with mud and impurities enters the washing tank through the feed inlet of the sand washer.

2. Washing and Separation: The spiral device inside the tank rotates continuously under the drive of a motor, stirring and tumbling the sand and gravel materials in the water. Heavier sand and gravel particles settle to the bottom of the tank and are gradually discharged from the outlet under the push of the spiral blades.

3. Overflow and Sludge Discharge: Lighter impurities such as mud and stone powder float in the water, forming a slurry, which is discharged from the overflow port at the top of the equipment, completing the effective separation of impurities.

4. Dewatering: During the discharge process, some of the lifted sand and gravel passes through a dewatering zone, where water is filtered out through a screen, ultimately outputting clean sand with lower moisture content.

III. Key Advantages of the Spiral Sand Washer

• High Cleanliness and Outstanding Results: The strong stirring and rinsing capabilities effectively break down the water vapor layer covering the surface of the sand particles, resulting in a cleanliness level far exceeding that of traditional equipment.

• Simple Structure and Durability: The overall structure is simple, and the transmission devices are isolated from water and sand, resulting in a low failure rate. Core components such as the spiral blades are made of wear-resistant materials, ensuring a long service life.

• High throughput, continuous operation: Suitable for large-scale, continuous production lines, meeting high-volume cleaning demands.

• Minimal fine sand loss, optimal gradation: Compared to some high-speed washing equipment, spiral sand washers offer gentler scouring, effectively reducing fine sand loss and ensuring good gradation of the finished sand.

IV. Wide Range of Applications

Spiral sand washers are widely used in sand and gravel plants, mines, building materials, transportation, chemical, water conservancy and hydropower, concrete mixing plants, and other industries for washing, classifying, and dewatering manufactured and natural sand. They are essential equipment for enhancing the added value of sand and gravel products.

V. Selection and Maintenance Tips

• Selection Considerations: Choose the appropriate model based on your material characteristics (e.g., mud content, particle size) and production requirements. Also, pay attention to core configurations such as plate thickness, spiral shaft material, and motor brand.

• Daily Maintenance: Regularly check the wear of the spiral blades, add or replace grease as needed, keep the equipment clean, and prevent scale buildup in the tank during long-term downtime.

In today's pursuit of high-quality building materials, a reliable spiral sand washer is a crucial element for achieving environmentally friendly, efficient, and high-profit operation of a sand and gravel production line. It is not merely a simple cleaning tool, but a "quality steward" that ensures the final quality of sand and gravel aggregates and enhances the product's market competitiveness.

If you are looking for a solution to your sand and gravel cleaning problems, a spiral sand washer is undoubtedly your ideal choice.