In Southeast Asia, agricultural waste materials such as palm oil shells and sugarcane bagasse, once a major waste source, have now become a vital source of renewable energy. However, high moisture content (30%-50%) directly impacts combustion efficiency and charcoal quality. Single-drum dryers maximize the value of biomass fuel by rapidly dehydrating it, helping businesses reduce energy costs and achieve sustainable development.

Core Requirements for Biomass Fuel Drying

1. Why is Biomass Fuel Drying Necessary?

• Low Combustion Efficiency: Wet palm oil shells (moisture content >40%) have a calorific value of only 2000 kcal/kg, while dried (<15%) can reach 4000 kcal/kg.

• Poor Charcoal Quality: High moisture content leads to uneven carbonization, resulting in brittle and low calorific value.

• High Transportation Costs: One ton of wet sugarcane bagasse contains 30%-50% moisture, resulting in significant transportation costs. 2. Southeast Asian Market Opportunities

• Palm Shell: Indonesia and Malaysia produce over 50 million tons annually. After drying, it can be used for power generation or biochar production.

• Bagasse: Thailand and Vietnam have abundant waste from sugar mills. After drying, it can replace coal and reduce carbon emissions.

How do single-drum dryers optimize biomass fuel production?

1. Efficient Dehydration, Boosting Energy Value

Rapid Drying: High-temperature airflow (300-400°C) directly contacts the material within the single drum, reducing moisture content to 10%-15% within 1-2 hours.

Case Study: After adopting the dryer, a palm oil mill in Malaysia increased its biomass power generation efficiency by 25%, saving over US$500,000 in annual coal costs.

2. Adaptability to a Variety of Biomass Feedstocks

• Palm Shell: Wear-resistant lining + detangling device to prevent fiber entanglement.

• Bagasse: Low-temperature, staged drying (to prevent sugar caramelization).

• Rice husks/wood chips: Adjustable speed to accommodate different particle sizes.

3. Environmental and Economic Benefits

• Fossil fuel replacement: Dried palm shells have a calorific value close to that of coal, reducing carbon emissions.

• Turning waste into revenue: Sugar mills can sell dried bagasse to power plants, generating additional revenue.

Biomass Dryer Selection Guide

1. Selection by Capacity

• Small (1-5 tons/hour): Suitable for small and medium-sized sugar mills or palm oil processing plants.

• Large (10-20 tons/hour): Suitable for biomass power plants or large-scale charcoal production operations.

2. Energy Adaptation

• Electric heating: Suitable for areas with stable power supply (such as industrial areas in Thailand).

• Gas/biomass fuel: Suitable for remote palm plantations (such as Sumatra, Indonesia).

3. Recommended Value-Added Features

• Waste heat recovery system: Reduces energy consumption by 30% and shortens the return on investment.

• Intelligent temperature control: Avoids over-drying and maintains the optimal calorific value of fuel.

Success Story: How are dryers transforming the biomass energy industry?

Case Study: Palm Shell Power Generation Project in Sumatra, Indonesia

Problem: Wet palm shells have a moisture content of 45%, resulting in low combustion efficiency and high power plant operating costs.

Solution: Install two 10-ton/hour biomass fuel dryers.

Results:

• Moisture content reduced to 12%, increasing power generation efficiency by 30%.

• Annual coal consumption reduced by 8,000 tons and carbon emissions by 12,000 tons.

As Southeast Asian countries promote renewable energy policies (such as Thailand's 2037 target of 30% biomass energy), dried palm shells and sugarcane bagasse will become key resources to replace fossil fuels. Single-drum dryers are not only production equipment but also strategic investments for companies to reduce costs, increase efficiency, and achieve carbon neutrality.

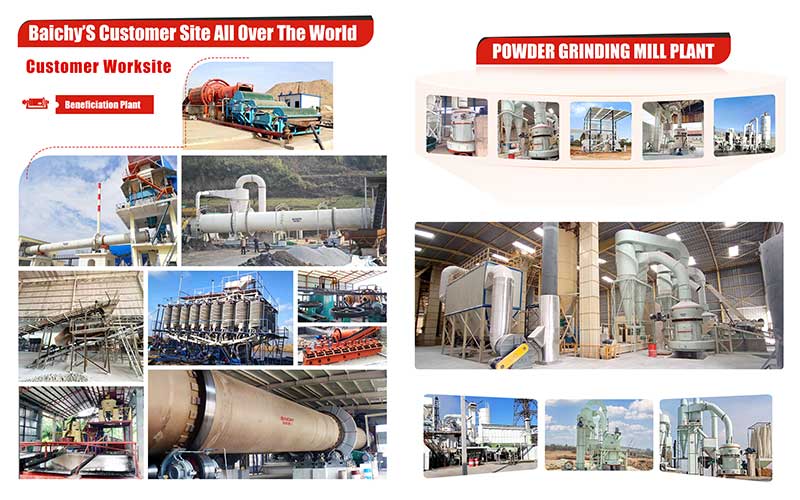

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)