In mining, aggregate production, and other fields, the efficiency and stability of the primary crushing stage directly determine the output and profitability of the entire production line. Choosing a reliable and efficient primary crushing unit is the cornerstone of project success.

Today, we will delve into a renowned classic model in the market—the high-efficiency PE500x750 jaw crusher—revealing how it has become a core profit driver for many enterprises.

I. Core Advantages

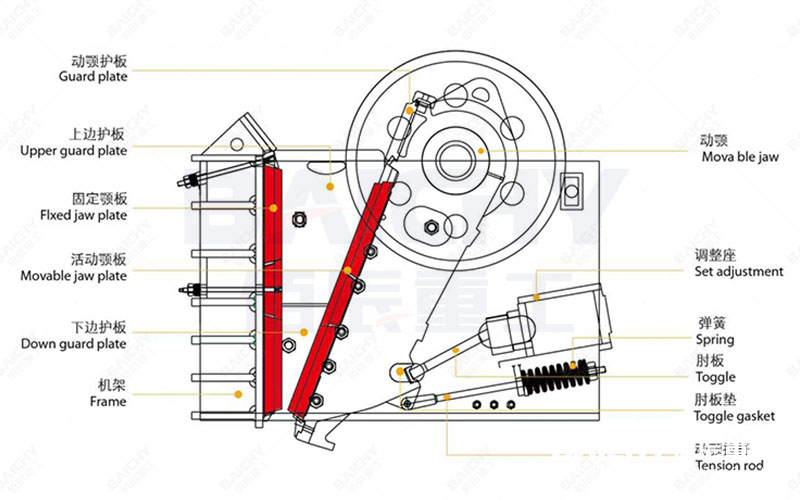

1. Robust Structure and Durability: Utilizing a high-quality, high-strength cast steel frame and moving jaw assembly, key components such as the eccentric shaft are forged, ensuring exceptional stability and an extended service life when crushing the hardest materials, significantly reducing downtime risks due to equipment failure.

2. Deep Cavity Crushing and Superior Output: The optimized cavity design and larger feed opening size (500mm x 750mm) not only allow for larger feed particle sizes but also significantly improve throughput and crushing efficiency. Its processing capacity typically ranges from 40 to 110 tons per hour, adjustable based on specific materials and discharge port settings to meet the needs of medium to large-scale production lines.

3. Dual-function toggle plate for enhanced overload protection: The equipment not only transmits power through the toggle plate but also designs it as a safety device. When uncrushable materials (such as iron blocks) enter the crushing chamber, the toggle plate will break first, protecting core components (such as the eccentric shaft and bearings) from damage. This ensures a high safety factor and low maintenance costs.

4. Flexible adjustment and uniform output: Utilizing a wedge-type discharge port adjustment device, operation is simple and quick, easily meeting the needs of different particle sizes. This ensures uniform particle shape and reasonable gradation of the final product, enhancing its market value.

5. Energy-saving and environmentally friendly, economical operation: The scientific motion trajectory and chamber design reduce wasted energy, allowing for efficient use of motor power and resulting in greater energy savings compared to traditional equipment. Furthermore, a comprehensive dustproof and noise reduction system can be equipped to actively respond to environmental protection production requirements.

II. Key Technical Parameters

• Feed Inlet Size: 500x750 mm

• Maximum Feed Size: 425 mm

• Discharge Inlet Adjustment Range: 50-100 mm

• Processing Capacity: 40-110 t/h

• Spindle Speed: 275 r/min

• Motor Power: 55-75 Kw

• Equipment Weight: Approx. 10.8 tons

III. Wide Range of Applications

The PE500x750 jaw crusher is an ideal primary crushing equipment, widely used in:

• Crushing of hard materials such as granite, basalt, and river pebbles.

• Coarse crushing of raw stone in mines and quarries.

• Primary crushing in construction waste treatment.

• Sand and gravel aggregate production bases for large-scale projects such as highways, railways, and water conservancy and hydropower.

Investing in a piece of equipment is not just about buying a machine, but also about choosing a long-term, reliable partner for your business. The high-efficiency PE500x750 jaw crusher, with its superior reliability, high output, and economical operating costs, will undoubtedly become a powerful force in enhancing your core competitiveness and maximizing profits.

Contact us now to obtain customized technical solutions and quotations, and let the PE500x750 lay a solid foundation for your success!