In the field of ultrafine powder processing, choosing equipment is not merely purchasing a machine, but rather choosing a profit model. For entrepreneurs aiming for large-scale production, the equipment's hourly output, long-term stability, and overall energy consumption directly determine market competitiveness and return on investment.

The HGM80 rock micro-powder mill is an industrial tool designed to meet this core need. This article will go beyond basic introductions and analyze from an investment and operation perspective how the HGM80 can become a core asset for capturing the high-end market.

I. How does the HGM80's high efficiency and low consumption translate into real profits?

One crucial piece of data in your provided information is that, at the same fineness and power, its output is more than twice that of air jet mills and stirred mills, while energy consumption is reduced by 30%. This is not just a technical parameter, but also a formula for profit calculation.

• Winning through volume: Assuming a traditional machine's hourly output is 2 tons, the HGM80 can reach over 4.5 tons. This means that tens of tons more material can be processed daily, enabling faster completion of large orders and seizing market opportunities.

• Savings Lead to Success: A 30% reduction in energy consumption translates to staggering electricity cost savings in large-scale, year-round production. The HGM80 offers not only faster production but also lower costs, directly contributing to your product's price advantage.

II. Unveiling the Long-Term Value Behind Superior Durability

Consumer parts typically last over a year, and 2-5 years when processing calcium carbonate. – This data is enough to shock any owner suffering from frequent parts replacements.

• Reduced Hidden Costs: Equipment downtime means lost output and maintenance labor costs. The ultra-long lifespan of the HGM80 grinding rollers and grinding rings significantly reduces unplanned downtime, ensuring production line continuity and stability.

• Clearer Return on Investment: Longer parts lifespan means lower long-term maintenance costs and more predictable operating expenses. This makes your initial equipment investment return model clearer and more optimistic. The HGM80 is not a consumable, but an asset that can generate stable value over the long term.

III. Engineering Wisdom of Precise and Controllable Particle Size from a Working Principle Perspective

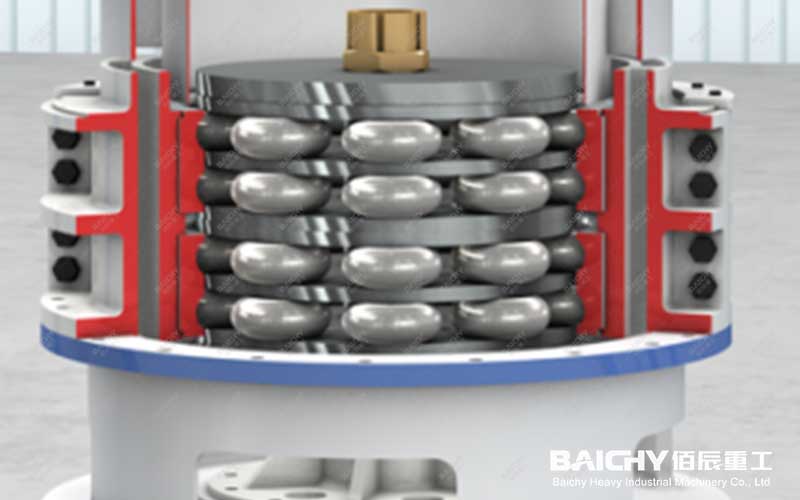

The detailed working principle you provided is excellent material showcasing our professional depth. The material undergoes repeated impact and grinding by three grinding rings and 21 grinding rollers, combined with a high-efficiency turbine classifier this process ensures that the finished particle size can be freely and precisely adjusted between 325 and 2500 mesh, achieving an ultra-fine level of D97≤5μm in a single pass.

• Meeting High-End Demands: This precise control capability allows your products to meet the stringent particle size distribution requirements of industries such as coatings, inks, and high-end plastics, thereby gaining a premium.

• One-Stop Solution: From feeding (≤20mm) to finished product packaging, the system boasts high integration and a smooth process, reducing losses and contamination in intermediate stages and ensuring the purity and consistency of the final product.

IV. Application Areas and Precautions

A wide range of application areas, from mining and metallurgy to food and pharmaceuticals, are clearly listed, demonstrating the powerful adaptability of the HGM80. Meanwhile, the thoughtful and professional Precautions section not only guides customers on proper use but also demonstrates our responsibility and service awareness as an equipment supplier, greatly enhancing customer trust.

From Equipment Supplier to Profit Partner Commitment

The HGM80 rock micro-powder mill is more than just a set of technical parameters. It's a complete solution for efficiency, durability, and profitability, based on our deep understanding of large-scale production scenarios. While your competitors are still struggling with frequent maintenance and high electricity bills, you've already established a strong cost and supply advantage with the HGM80.

Now, it's time to have a conversation to enhance your company's core competitiveness. We welcome you to provide specific material samples and production capacity targets, and we will conduct free grinding tests and provide a detailed investment benefit analysis report.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing onstone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.