For many small and medium-sized quarries, engineering contractors, or newly established mining companies, large production lines with capacities exceeding 100 tons are prohibitively expensive, while equipment with insufficient capacity fails to meet profitability requirements.

It is against this market backdrop that rock crushers in the 10-20 ton/hour range, considered the golden capacity range, have become the dominant force in the market due to their superior cost-effectiveness and wide applicability.

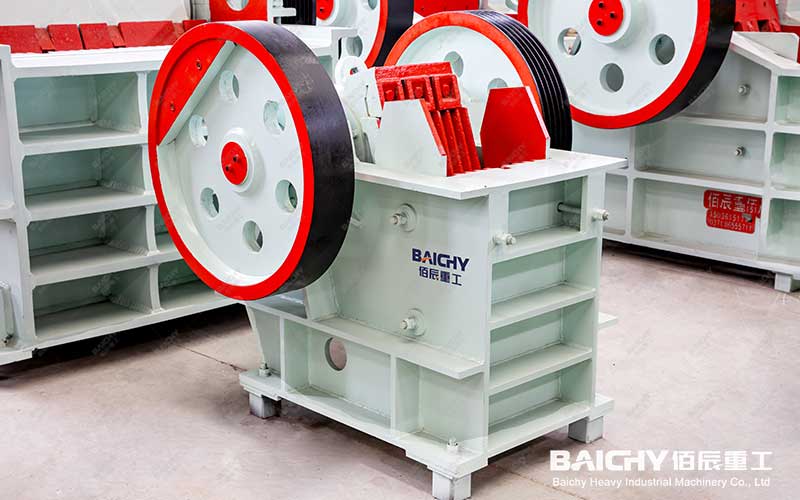

| Product Model | PE250x400 Jaw Crusher |

|---|---|

| Maximum Feed Size | ≤ 4210 mm |

| Outlet Adiusting Range | 25-60 mm |

| Processing Capacity | 5-20tph |

| Motor Power | 15 kW |

| Core Structure | Deep cavity fracture |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

As a manufacturer with 20 years of experience in designing and manufacturing mining crushing equipment, we understand that excellent equipment is not merely a matter of stacked parameters, but also a profound understanding of application scenarios, user habits, and return on investment. This article will combine our years of practical experience to provide a comprehensive analysis of the core value of 10-20 ton/hour rock crushers.

I. Why is 10-20 ton/hour considered the golden capacity?

This capacity range precisely covers the most dynamic market demand, and its advantages are reflected in:

• Optimal Return on Investment: Equipment purchase costs, installation and infrastructure construction costs, and subsequent operation and maintenance costs are relatively controllable, quickly bringing stable returns to investors with less financial pressure.

• Wide Range of Applications: Perfectly matches secondary crushing in small and medium-sized limestone, granite, and river pebble quarries; meets the on-site production needs of roadbed aggregates for highway and railway projects; and is a core component of construction waste recycling production lines.

• Energy Consumption and Output Balance: Achieves an optimal balance between energy consumption and output, making the aggregate cost per unit of energy more competitive in the market, aligning with green and efficient production principles.

II. How to Forge the Core Reliability of Equipment?

In harsh mining environments, reliability is the lifeline of equipment. Leveraging 20 years of technological accumulation, we ensure the long-term stable operation of our equipment in the following key areas:

• Core Crushing Technology: Whether it's the deep-cavity crushing structure of the jaw crusher or the heavy-duty rotor design of the impact crusher, we have conducted countless optimizations and on-site verifications to ensure that when crushing high-hardness rocks, we can guarantee production capacity while effectively controlling the wear rate of vulnerable parts such as hammers and jaw plates.

• Robust Machine Structure: The main frame is welded from high-quality steel plates, with reinforced ribs in key areas and stress-relief processes to ensure the equipment remains undeformed and crack-free under long-term high-intensity vibration, providing a stable foundation.

• Power and Transmission System: Matching high-efficiency, energy-saving electric motors or diesel engines, employing high-strength V-belts or flexible transmission technology, ensuring smooth transmission and strong overload protection to prevent equipment damage caused by material blockage.

III. Providing Comprehensive Solutions

We believe that delivering a piece of equipment is just the beginning of our cooperation. Based on 20 years of experience, we can provide you with more valuable support:

• Scientific Selection Recommendations: What are the characteristics of your raw materials (hardness, moisture content, mud content)? What are your target output particle size requirements? Based on this information, we can scientifically recommend the most suitable crusher type (such as jaw crusher, cone crusher, impact crusher, etc.) to avoid under-powered equipment or wasted capacity.

• Optimized Process Layout: Even small and medium-sized production lines involve feeding, crushing, screening, and conveying processes. We can provide reasonable process layout suggestions to help you optimize your processes, reduce bottlenecks, and improve overall line efficiency.

• Wear Parts Lifecycle Management: We provide high-quality original equipment manufacturer (OEM) wear parts and can predictively provide replacement suggestions and inventory plans based on your production data, helping you plan downtime and maximize equipment utilization.

In an increasingly competitive market environment, choosing a technologically mature, reliable, and capacity-matched crushing machine is key to reducing operating costs and improving profitability. A 10-20 ton/hour rock crusher, like a steady and reliable partner, provides solid support for every step of your business development.

With 20 years of accumulated professional knowledge and craftsmanship, we aspire to be your most trusted partner. Feel free to contact us anytime to discuss your specific needs, and let's work together to create efficient and sustainable crushing production solutions.